Composite material for multifunctional rubber and plastic car foot mats and preparation method

A technology for car floor mats and composite materials, applied in the field of multifunctional rubber-plastic composite materials for car floor mats and its preparation, can solve the problems of high cost, insufficient antibacterial effect and wide range, etc., and achieve low production price and antibacterial performance Good, long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

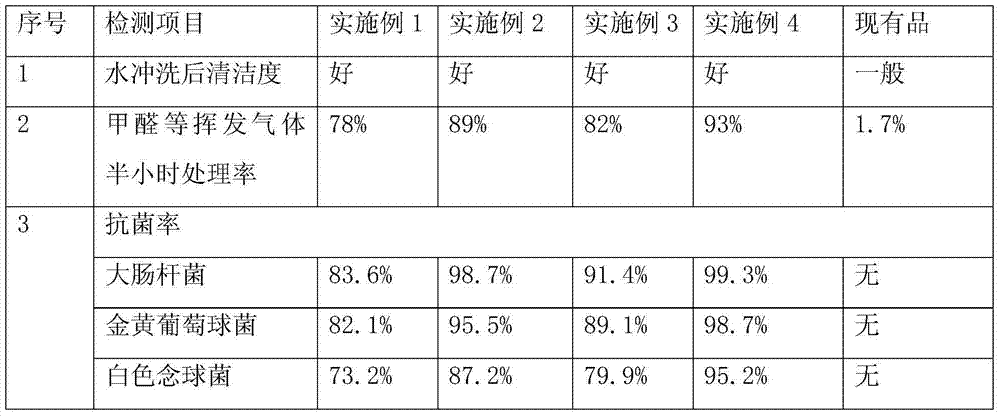

Examples

Embodiment 1

[0027] Embodiment 1: a kind of composite material that multi-functional rubber and plastic car floor mat is used, and its raw material component and parts by weight are:

[0028] Polyvinyl chloride (medical grade, molecular weight 2500): 50 parts;

[0029] Styrene-isoprene-styrene block copolymer: 25 parts;

[0030] Tributyl citrate: 40 parts;

[0031] Epoxy resin (E-51): 5 parts;

[0032] 2-Methylimidazole: 0.5 parts;

[0033] Nano anatase titanium dioxide: 5 parts;

[0034] Calcium carbonate: 20 parts;

[0035] Antibacterial agent: 1 part;

[0036] Epoxidized soybean oil: 3 parts;

[0037] Polyoxyethylene polyoxypropylene polyether: 1 part;

[0038] Calcium zinc stabilizer: 2 parts.

[0039] Its preparation method is:

[0040] First add polyvinyl chloride, tributyl citrate, epoxy resin, nano-titanium dioxide, calcium carbonate, epoxy soybean oil, antibacterial agent, polyoxyethylene polyoxypropylene polyether and calcium zinc stabilizer into the stirring tank, at te...

Embodiment 2

[0043] A composite material for a multifunctional rubber and plastic car mat, its raw material components and parts by weight are:

[0044] Polyvinyl chloride (medical grade, molecular weight 2500): 100 parts;

[0045] Styrene-isoprene-styrene block copolymer: 5 parts;

[0046] Tributyl citrate: 100 parts;

[0047] Epoxy resin (E-51): 8 parts;

[0048] 2-Methylimidazole: 1 part;

[0049] Nano anatase titanium dioxide: 10 parts;

[0050] Calcium carbonate: 30 parts;

[0051] Antibacterial agent: 2 parts;

[0052] Epoxidized soybean oil: 10 parts;

[0053] Polyoxyethylene polyoxypropylene polyether: 2 parts;

[0054] Calcium zinc stabilizer: 5 parts.

[0055] Its preparation method is:

[0056] First add polyvinyl chloride, tributyl citrate, epoxy resin, nano-titanium dioxide, calcium carbonate, epoxy soybean oil, antibacterial agent, polyoxyethylene polyoxypropylene polyether and calcium zinc stabilizer into the stirring tank, at temperature Stir at 40°C for 1 hour at...

Embodiment 3

[0059] A composite material for a multifunctional rubber and plastic car mat, its raw material components and parts by weight are:

[0060] Polyvinyl chloride (medical grade, molecular weight 2500): 75 parts;

[0061] Styrene-isoprene-styrene block copolymer: 15 parts;

[0062] Tributyl citrate: 60 parts;

[0063] Epoxy resin (E-51): 6.5 parts;

[0064] 2-Methylimidazole: 0.75 parts;

[0065] Nano anatase titanium dioxide: 7.5 parts;

[0066] Calcium carbonate: 25 parts;

[0067] Antibacterial agent: 1.5 parts;

[0068] Epoxidized soybean oil: 6.5 parts;

[0069] Polyoxyethylene polyoxypropylene polyether: 1.5 parts;

[0070] Calcium zinc stabilizer: 3.5 parts.

[0071] Its preparation method is:

[0072]First add polyvinyl chloride, tributyl citrate, epoxy resin, nano-titanium dioxide, calcium carbonate, epoxy soybean oil, antibacterial agent, polyoxyethylene polyoxypropylene polyether and calcium zinc stabilizer into the stirring tank, at temperature At 30°C, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com