Method of using catering waste shrimp shells for continuous production of compound amino acid oligopeptide chelated calcium and chitin

A compound amino acid and chelated calcium technology, applied in the biological field, can solve the problems of high cost of compound amino acid short peptide chelated calcium, insufficient product safety, loss of amino acid quality, etc., and achieve good nutritional value, high utilization rate, and efficient recovery The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

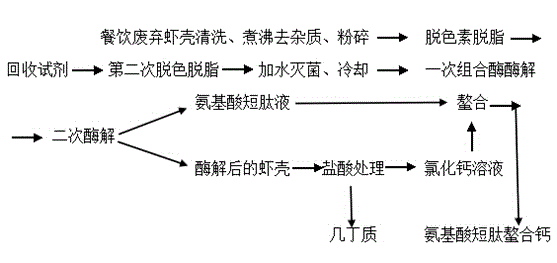

Image

Examples

Embodiment 1

[0027] Embodiment 1 illustrates the method for utilizing shrimp shells to continuously produce compound amino acid short peptide chelated calcium and chitin.

[0028] (1) Pretreatment of waste catering shrimp shells:

[0029]50 g of shrimp shells were ultrasonically cleaned 3 times, each time for 30 minutes to remove most of the particulate impurities, boiled to remove various impurities such as edible oils, and then dried, crushed (60 mesh) and put into a reaction vessel, adding Food grade anhydrous ethanol and ethyl acetate v / v (1:1) 400ml, 60 ℃ assisted by ultrasound for 24 hours, after suction filtration, use a rotary evaporator to recover the used ethanol and ethyl acetate from the filtrate, and then use the recovered ethanol The once-treated shrimp shells are treated again with ethyl acetate to ensure thorough treatment, and finally the treated shrimp shells are washed with water for 2 to 3 times, and dried to obtain depigmented and defatted shrimp shells.

[0030...

Embodiment 2

[0038] Embodiment 2 illustrates the method for utilizing shrimp shells to continuously produce compound amino acid short peptide chelated calcium and chitin.

[0039] (1) Pretreatment of waste catering shrimp shells:

[0040] 50g shrimp shells were ultrasonically cleaned 3 times, each time for 30 minutes to remove most of the particle impurities, boiled to remove various impurities such as edible oils, then dried, crushed (60 mesh) and put into a reaction vessel, adding food grade Absolute ethanol and ethyl acetate v / v (3:1) 500ml, 70 ℃ assisted by ultrasound for 25 h, after suction filtration, use a rotary evaporator to recover the used ethanol and ethyl acetate from the filtrate, and then use the recovered ethanol and acetic acid The once-treated shrimp shells are treated again with ethyl ester to ensure thorough treatment. Finally, the treated shrimp shells are washed with water for 2 to 3 times, and dried to obtain depigmented and defatted shrimp shells.

[00...

Embodiment 3

[0048] Embodiment 3 illustrates the method for utilizing shrimp shells to continuously produce compound amino acid short peptide chelated calcium and chitin.

[0049] (1) Pretreatment of waste catering shrimp shells:

[0050] 50g shrimp shells were ultrasonically cleaned 3 times, each time for 30 minutes to remove most of the particle impurities, boiled to remove various impurities such as edible oils, then dried, crushed (60 mesh) and put into a reaction vessel, adding food grade Absolute ethanol and ethyl acetate v / v (3:1) 150ml, 25 ℃ assisted by ultrasound for 25 h, after suction filtration, use a rotary evaporator to recover the used ethanol and ethyl acetate from the filtrate, and then use the recovered ethanol and acetic acid The once-treated shrimp shells are treated again with ethyl ester to ensure thorough treatment. Finally, the treated shrimp shells are washed with water for 2 to 3 times, and dried to obtain depigmented and defatted shrimp shells.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com