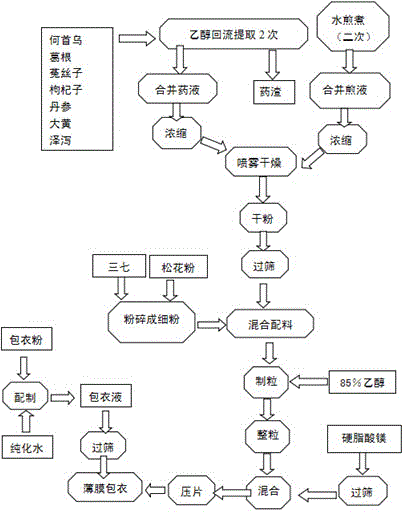

Preparation process of lipid-lowering tablet

A preparation process and tablet compression technology, applied in the field of medicine, can solve the problems of high safety and inability to meet the cost of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. The crushing of materials, Panax notoginseng powder is crushed into fine powder, passed through 80-mesh sieve, pine pollen is directly passed through 80-mesh sieve, and the raw materials of Polygonum multiflorum, Pueraria lobata, Cuscuta, Lycium barbarum, Salvia miltiorrhiza, Rhubarb, Alisma, and Yinchen Bawei raw materials are crushed into The coarse powder is passed through a 24-mesh sieve.

[0020] 2 Alcohol extraction, the coarse powder sieved in the previous step is reflux extracted with 3 times the amount of 70% ethanol, extracted twice, each time for 3 hours, filtered, the combined filtrate reclaims ethanol and concentrates to a relative density of 1.1g / ml (80°C) extract. 3. Decoct in water, decoct the remaining medicinal dregs after alcohol extraction, the amount of water is also 3 times the volume of the medicinal dregs, each time for 2 hours, combine the decoction, filter, and concentrate the filtrate to a relative density of 1.3g / ml (90°C ) thick paste. ...

Embodiment 2

[0024] 1. The crushing of materials, Panax notoginseng powder is crushed into fine powder, passed through 80-mesh sieve, pine pollen is directly passed through 80-mesh sieve, and the raw materials of Polygonum multiflorum, Pueraria lobata, Cuscuta, Lycium barbarum, Salvia miltiorrhiza, Rhubarb, Alisma, and Yinchen Bawei raw materials are crushed into The coarse powder is passed through a 50-mesh sieve.

[0025] 2 Alcohol extraction, the coarse powder sieved in the previous step is reflux extracted with 3 times the amount of 70% ethanol, extracted twice, each time for 3 hours, filtered, the combined filtrate reclaims ethanol and concentrates to a relative density of 1.08g / ml (80°C) extract. 3 Decoct in water, decoct the remaining medicinal residues after alcohol extraction with water, the amount of water is also 3 times the volume of the medicinal residues, each time for 2 hours, combine the decoctions, filter, and concentrate the filtrate to a relative density of 1.28g / ml (90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com