A double-layer sleeve type corona plasma generator

A plasma and generating device technology, applied in the field of plasma generating devices, can solve the problems of high energy consumption in single-stage reactor processing, complex components of industrial waste gas, and wide equipment footprint, and achieve compact structure and uneven coefficient of electric field The effect of large size and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

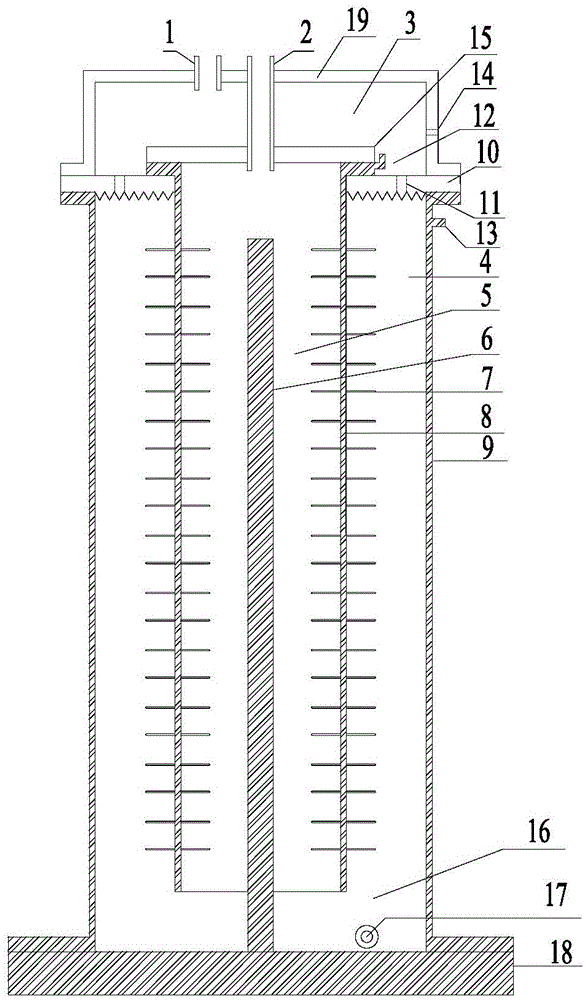

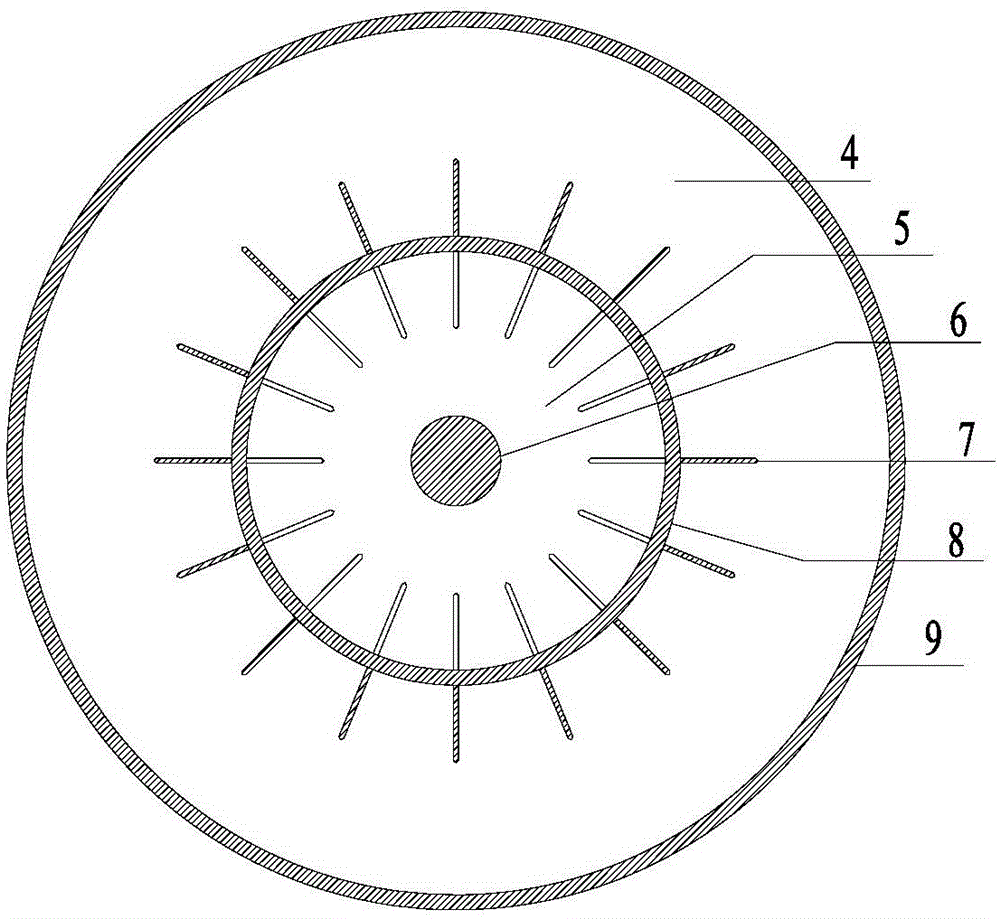

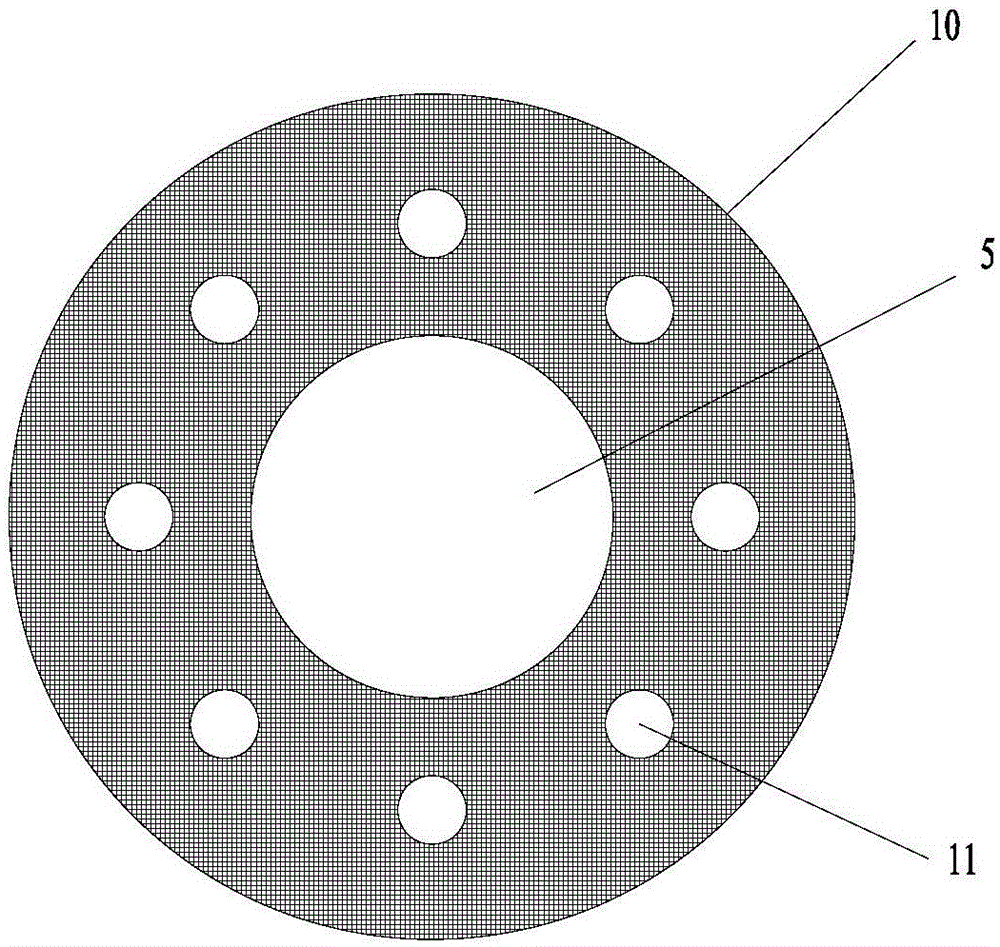

[0028] see Figure 1 to Figure 4 , a double-layer sleeve type corona plasma generating device of the present invention includes a metal base 18 and an outer metal sleeve 9 arranged on the metal base 18, and the top of the outer metal sleeve 9 is sequentially provided with insulating baffles 10 and an outer insulating shell 19, the center of the insulating baffle 10 is provided with a through hole, and a number of air passage holes 11 are evenly opened in the upper direction of the insulating baffle 10; the inner metal sleeve 8 passes through the insulating baffle The central through hole of the plate 10 is fixed on the insulating baffle 10, a number of needle electrodes 7 are arranged on the side wall of the inner metal sleeve 8, and the number of needle electrodes 7 are perpendicular to the side wall of the inner metal sleeve 8, The inner ground electrode 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com