Boron-containing polyethylene glycol fatty acid ester surfactant

A surfactant, polyethylene glycol technology, applied in the directions of dissolution, chemical instruments and methods, chemical/physical processes, etc., to achieve good emulsification performance, improve esterification rate, and reduce surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

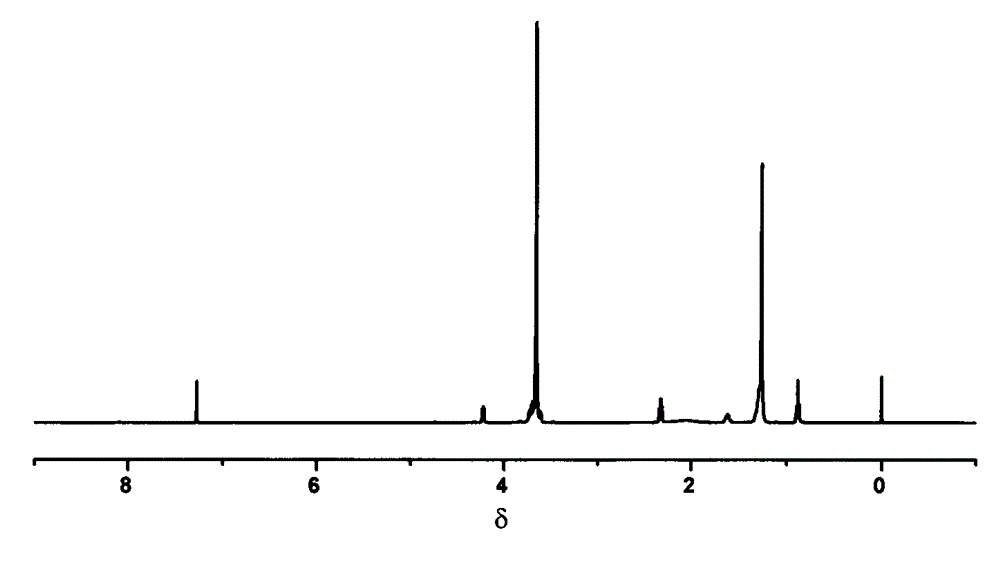

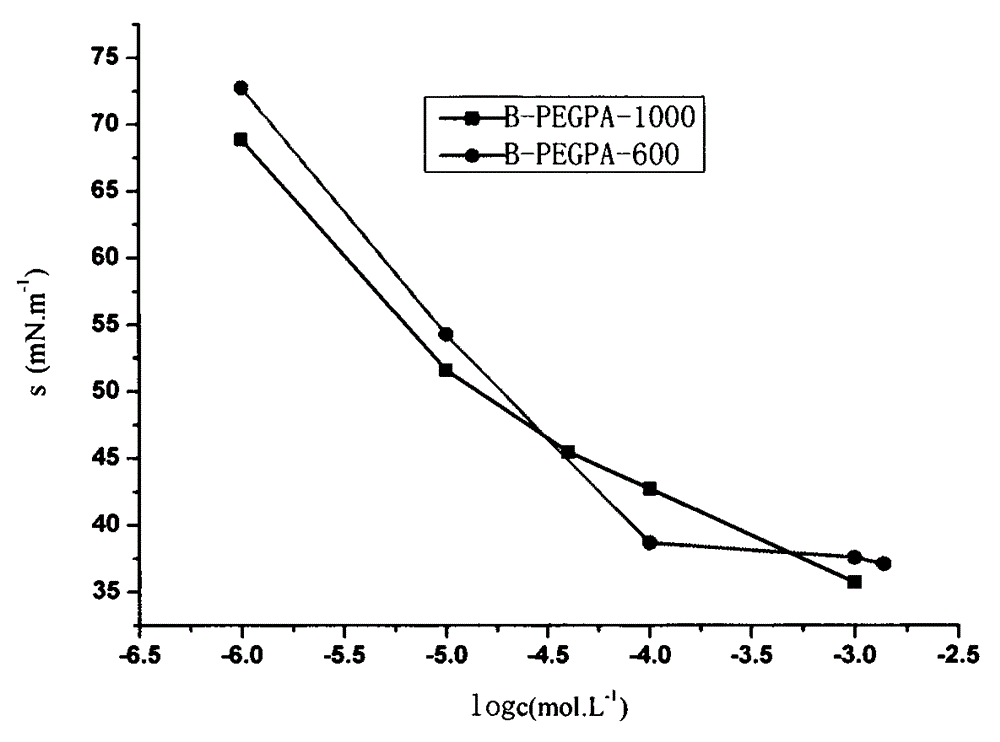

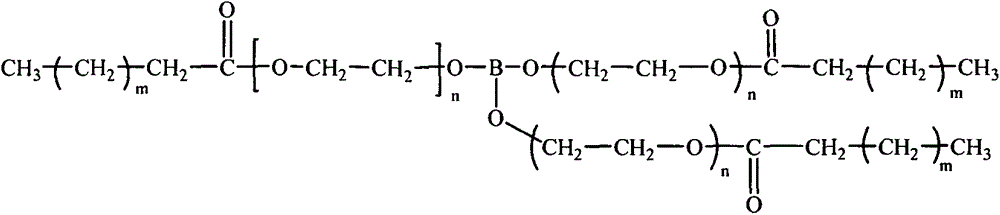

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, the esterification reaction of boric acid and PEG

[0015] Put 10g of PEG-600 and 350mg of boric acid in a molar ratio of 3:1 into a three-necked flask, install an electric stirrer, a water separator, a thermometer and a reflux condenser, add 0.8% terephthalic acid, and 100mL of water-carrying agent xylene , reflux at 140°C for 2 hours, distill off water and xylene under reduced pressure, and dry to obtain polyethylene glycol borate.

[0016] Embodiment 1, the esterification reaction of boric acid-PEG and fatty acid

[0017] Weigh 5g polyethylene glycol borate, react with 2g palmitic acid in a molar ratio of 1:3, catalyst sodium bisulfate monohydrate (0.8% of the total mass) and water-carrying agent xylene are put into the installation electric stirrer , a water separator, a thermometer, and a three-necked flask with a reflux condenser, reflux at 140 ° C for 5 hours, filter to remove the catalyst after the reaction, and distill under reduced pressure to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com