3D (three dimensional) printer controller and 3D printer control method

A technology of 3D printers and controllers, applied in the electromechanical field, can solve problems such as over-processing of workpieces, affecting processing accuracy, and affecting processing efficiency, and achieve the effects of fast command connection, improved processing efficiency, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail and completely below in conjunction with the embodiments and the accompanying drawings.

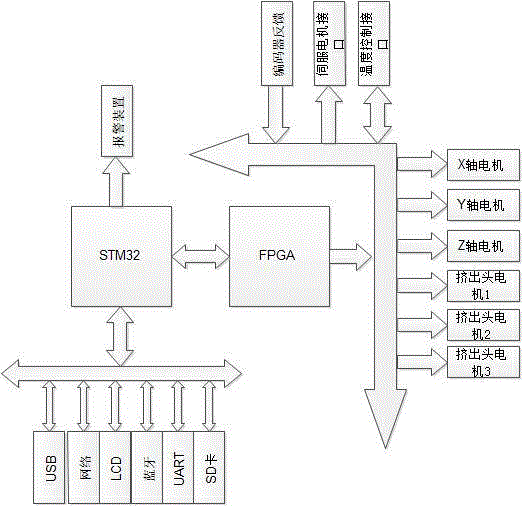

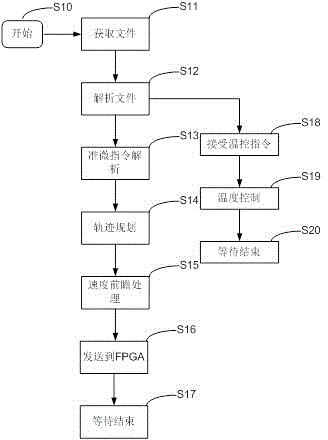

[0042] The 3D printer controller of the present invention adopts a dual-core architecture structure of MCU (Micro Control Unit) and FPGA (Field Programmable Gate Array). Micro control unit MCU is used for motion control calculation and control of man-machine interface, while FPGA is used for sequential logic generation and control of printing equipment. Such a dual-core architecture makes the division of labor of the whole system clear, thereby improving the real-time performance of the whole system, increasing the printing stability and accuracy; at the same time, the trajectory planning algorithm is introduced into the software, which greatly improves the processing efficiency. In addition, the network controller and Bluetooth are integrated in the system, so that it can easily interact with other devices, especially with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com