Method for inducing high-nitrogen-doped photo-reduced graphene oxide film through fluorination

A graphene film and fluorination technology, which is applied in the field of simple preparation of macro-graphene materials, can solve the problems of complex process and ineffective adjustment of graphene band gap, and achieve the effect of convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

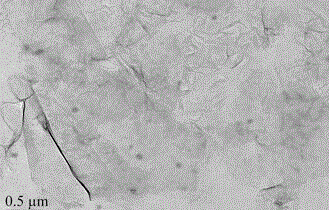

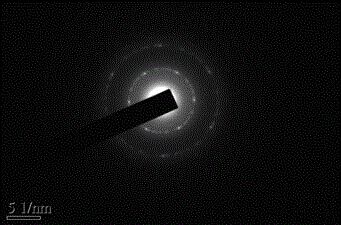

Image

Examples

Embodiment

[0027] (1) Mix 8g of flake graphite, 8g of sodium nitrate and 384mL of commercially available concentrated sulfuric acid in an ice bath; then slowly add 48g of potassium permanganate, stir with a magnetic force and heat at 35 degrees Celsius for 2 hours; then add 320mL to Deionized water was stirred for 15 minutes, and then 800 mL deionized water and 40 mL HO were added 2 o 2 Stirring for 10 minutes gave a green suspension.

[0028] (2) Add 0.0001 mol / L dilute nitric acid solution to the green suspension obtained in step (1) for washing, and then centrifuge at a centrifugal speed of 14000 rpm to obtain a precipitate.

[0029] (3) Repeat step (2) 3 times.

[0030] (4) Add deionized water to the suspension obtained in step (3), and centrifuge at 14,000 rpm to obtain a precipitate.

[0031] (5) Repeat step (4) adding deionized water and then centrifuging for 10 times to ensure that no other impurities are contained; a graphene oxide solution is obtained.

[0032] (6) Drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com