Cassava alcohol wastewater whole mash anaerobic high temperature fermentation tank water distribution system

A cassava alcohol and high-temperature fermentation technology, which is applied in anaerobic digestion treatment, food industry wastewater treatment, waste fuel, etc., can solve the problems of water distribution system wear and corrosion, treatment efficiency decline, uneven water distribution, etc., and achieve uniform water distribution , the effect of large service area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

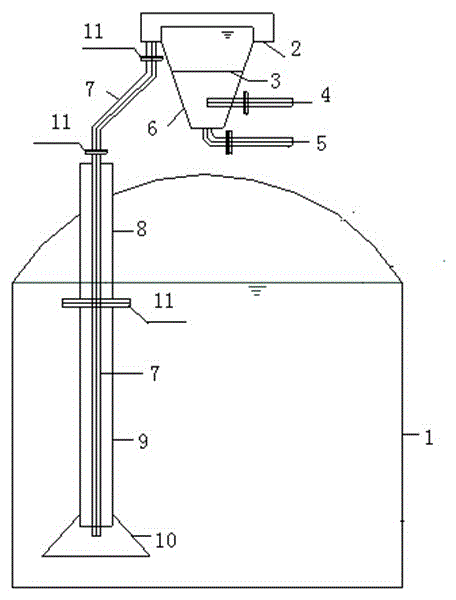

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

[0017] The anaerobic full-mash fermenter water distribution system for cassava alcohol waste mash includes an umbrella-shaped water separator 10 arranged at the bottom of the fermenter 1, and the umbrella-shaped water separator 10 is connected to a vertically arranged water distribution pipe. The water distribution pipe includes Two layers, the outer water distribution pipe, 316L stainless steel outer water distribution pipe 8 is used above the liquid surface of the fermentation tank, and the carbon steel seamless steel pipe is used below the liquid surface. A natural water seal is formed between the outer layer and the inner layer to ensure There is no leakage of biogas; the inner water distribution branch pipe 7 is connected to a water distributor installed outside the fermentation tank through a flange 11, and the water distributor will deposit part of the mud and sand here ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com