Autoclaved aerated concrete material prepared by adding saponin air entraining agents

A saponin-based air-entraining agent, autoclaved air-entraining technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of low slurry water-material mixing ratio, low pass rate of block products, poor pouring stability, etc. Achieve good sound absorption and sound insulation effects, high masonry strength utilization coefficient, and not easy to shrink the blank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

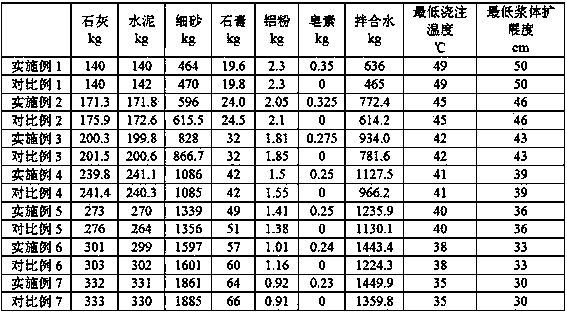

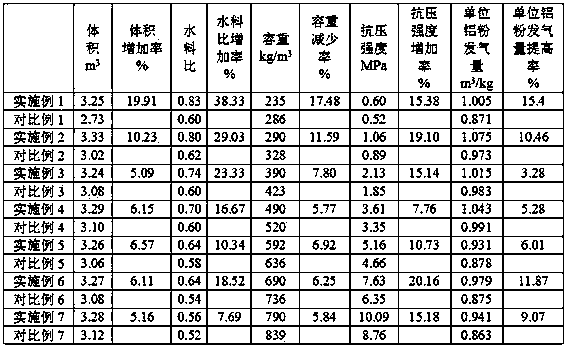

Embodiment 1

[0041] The remaining amount is mixed with water, stirred several times, controlled the temperature of the slurry, and when the temperature was ≥49 ° C, the water -soluble aluminum powder ointment 2.3 kg, the saponin air induction agent (with saponin) 0.35 kg and water 2.0 kg 2.0 kgThe formation of suspension, stirring for several times to control the slurry extension, when the extension is ≥50 cm, the content of the pulp injection is 3.24 m 3 After the mold is completed, the mold is moved to the quiet stop room for several time. After the body meets the solidification requirements, remove the quiet parking room, cut out the mold according to the product specifications, and the mold is moved to the high temperature of the steaming kettle., To accelerate the development of hydrated minerals and promote the post -intensity development of the body. After the product is out of the kettle, it has been raised for 7 days in the warehouse to make light porous steaming pressure and reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com