Method for preparing 3-methylamino-4-nitrophenoxyethanol

A technology of nitrophenoxyethanol and methylamino group is applied in the field of preparation of 3-methylamino-4-nitrophenoxyethanol, can solve the problems of high solvent tetrahydrofuran price, difficult recovery, low yield and the like, and achieves a reduction in The effect of recovering operating costs, reducing solvent costs, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

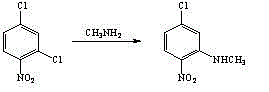

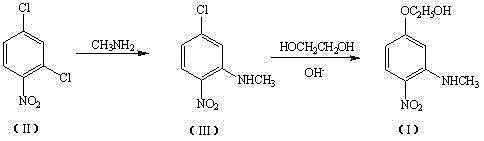

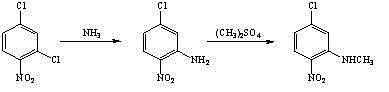

[0036] (1) Preparation of 3-methylamino-4-nitrobenzene chloride

[0037]Add 50g (0.260mol) of 2,4-dichloronitrobenzene and 150g of methanol into a four-neck flask, stir and raise the temperature to reflux, add 47.6g (0.613mol) of 40w% methylamine aqueous solution dropwise, and the dropping time is controlled After 1h, after the dropwise addition, keep the reflux temperature and react for 15h, the reaction solution is orange transparent liquid, slowly cool down to 10°C by passing through ice-salt water, keep warm and crystallize for 30min, then filter and dry to obtain orange 3-methylamino-4- The crude product of nitrochlorobenzene was beaten with 60g of methanol, filtered and dried at 70°C to obtain 34.5g of orange intermediate 3-methylamino-4-nitrochlorobenzene, the HPLC purity was 99.65%, and the yield was 71.00 %.

[0038] (2) Preparation of crude 3-methylamino-4-nitrophenoxyethanol

[0039] Add 5.5g NaOH (the first batch of alkali) and 105g (1.692mol) ethylene glycol int...

Embodiment 2~4

[0043] The same operation as that in step (1) of Example 1 is adopted, except that different amounts of methanol, methylamine aqueous solution, different concentrations of methylamine aqueous solution and different reaction times are used. The data obtained in Examples 1 to 4 are shown in Table 1:

[0044] Table 1

[0045]

[0046] Can find out according to table 1, adopt the methyl alcohol of different consumption, methylamine aqueous solution, methylamine aqueous solution of different concentration and different reaction time, all can have obvious effect to the purity and the yield of 3-methylamino-4-nitrochlorobenzene Impact, thereby affecting the purity and yield of the final product 3-methylamino-4-nitrophenoxyethanol.

Embodiment 5~8

[0048] Adopt and embodiment 1 step (2) in same operation, difference is to select the ethylene glycol of different consumption, NaOH and different reaction time, the data obtained in embodiment 1 and embodiment 5~8 are as shown in table 2:

[0049] Table 2

[0050]

[0051] Wherein, NaOH is one-time addition among the embodiment 6, and other embodiments are to add in batches.

[0052] Can find out according to table 2, adopt the ethylene glycol of different consumption, NaOH and different reaction time, all can have obvious influence to the purity and the yield of 3-methylamino-4-nitrophenoxyethanol crude product, thereby influence final The purity and yield of the product 3-methylamino-4-nitrophenoxyethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com