Preparation apparatus of microspheric polymer coating

A polymer coating and preparation device technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the requirement that polymers are difficult to achieve fusion ignition, and it is difficult to meet the uniformity of microsphere polymer coating Requirements and other issues to achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

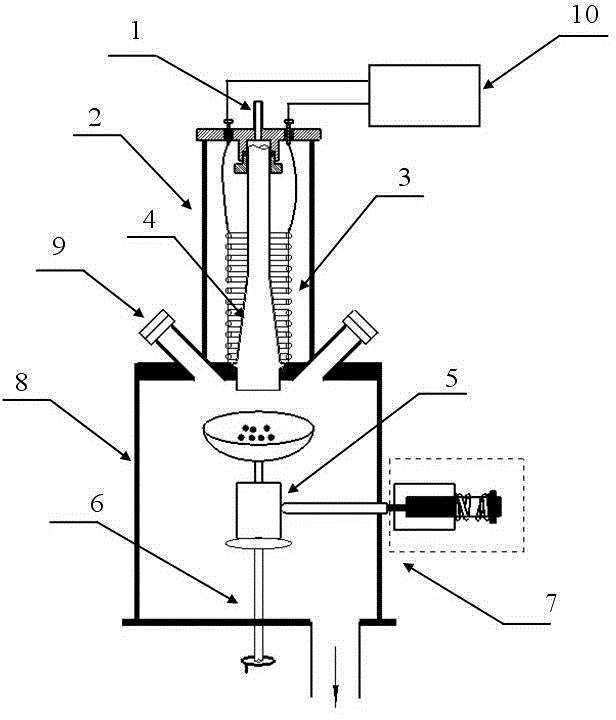

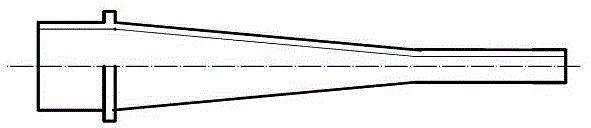

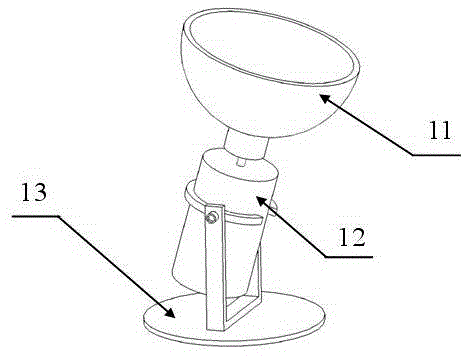

[0015] figure 1 It is a structural schematic diagram of the microsphere polymer coating preparation device of the present invention, in figure 1 Among them, the quartz resonant cavity 4 is located in the inductance coil 3, and the two lead wires of the inductance coil 3 are drawn out from the terminal on the top of the device, and connected to the radio frequency power supply 10, and the number of turns of the inductance coil 3 is adjustable to realize the adjustment of the plasma generation area. The inductance coil 3 is located in the radio frequency shield 2 to shield the high frequency signal of the inductance coil 3 . The intake pipe 1 is connected to the top of the quartz resonant cavity 4 , and the bottom of the quartz resonant cavity 4 is connected to the vacuum chamber 8 . The reaction gas is coupled to the plasma by the radio frequency indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com