Stoving varnish writing board and preparing method for stoving varnish writing board

A technology of writing board and baking varnish, which is applied in the field of teaching equipment, can solve the problems of physical and mental health threats to teachers and students, excessive dust, and short life, and achieve the effects of reducing eye damage, low gloss, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

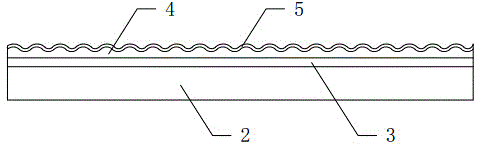

[0054] A lacquered writing board, see figure 1 As shown, it includes a substrate 2, and the upper surface of the substrate 2 is sequentially provided with a passivation layer 3, a baking paint layer 4 and an impermeable layer 5.

[0055]The material of the impermeable layer 5 is acrylic resin. The material of the baking paint layer 4 is baking paint, and the baking paint is composed of the following raw materials by mass percentage: acrylic resin 30%, dispersant 1%, coloring pigment 2%, anti-settling agent 8%, water 22%, urea-melamine-formaldehyde resin 13% %, catalyst 1%, wear-resistant filler 16%, matting agent 2%, auxiliary agent 5%, made by mixing, grinding and filtering. Among them, the dispersant is PAA-402 dispersant; the anti-settling agent is FP-88 anti-settling agent; the coloring pigment is dark green coloring pigment; the matting agent is white carbon black; the wear-resistant filler is a mixture of ceramic powder and graphite powder, wherein The mass ratio of ce...

Embodiment 2

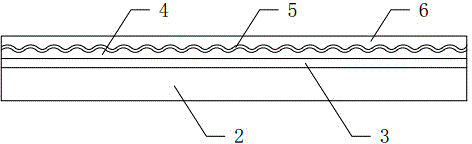

[0065] A lacquered writing board, see figure 2 As shown, it includes a substrate 2, and the upper surface of the substrate 2 is sequentially provided with a passivation layer 3, a baking paint layer 4, an impermeable layer 5 and a coating layer 6.

[0066] The material of the impermeable layer 5 is acrylic resin. The material of the baking paint layer 4 is baking paint, and the baking paint is composed of the following raw materials by mass percentage: acrylic resin 34%, dispersant 0.5%, color pigment 1.5%, anti-settling agent 8%, water 24%, urea-melamine-formaldehyde resin 10% %, catalyst 1%, wear-resistant filler 14%, matting agent 2%, auxiliary agent 5%, made by mixing, grinding and filtering. Among them, the dispersant is PAA-402 dispersant; the anti-settling agent is FP-88 anti-settling agent; the coloring pigment is dark green coloring pigment; the matting agent is white carbon black; the wear-resistant filler is a mixture of ceramic powder and graphite powder, wherein...

Embodiment 3

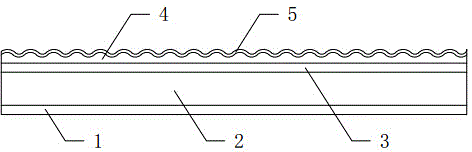

[0077] A lacquered writing board, see image 3 As shown, it includes a substrate 2, the upper surface of the substrate 2 is provided with a passivation layer 3, a baking paint layer 4 and an impermeable layer 5 in sequence; the backside of the substrate 2 is provided with a back paint layer 1.

[0078] The material of the impermeable layer 5 is acrylic resin. The material of the baking paint layer 4 is baking paint, and the baking paint is composed of the following raw materials by mass percentage: acrylic resin 35%, dispersant 0.5%, color pigment 1.5%, anti-settling agent 10%, water 22%, urea-melamine-formaldehyde resin 10% %, catalyst 1.5%, wear-resistant filler 11%, matting agent 2.5%, auxiliary agent 6%, made by mixing, grinding and filtering. Among them, the dispersant is PAA-402 dispersant; the anti-settling agent is FP-88 anti-settling agent; the coloring pigment is dark green coloring pigment; the matting agent is white carbon black; the wear-resistant filler is a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com