A high-yield oil lotus garden green coccus and its application

A technology of green algae and biodiesel, which is applied in the field of high-yield oil-producing green algae, can solve the problems of slow growth of algae species, high equipment cost, and small cell volume, so as to reduce the demand for nutrients and reduce the The effect of culture cost and large cell volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

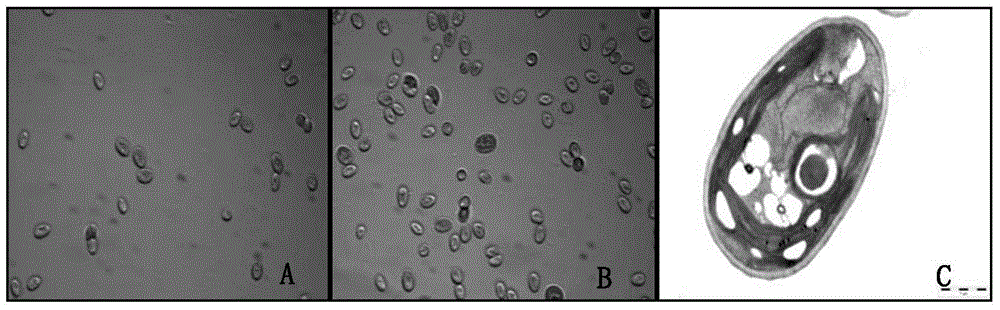

[0040] The Chlorococcum lianyuanensis of the present invention is isolated from an artificial lake with shallow water depth. The Chlorococcum lianyuanensis is single-celled, oval, with thinner or irregularly thickened cell walls, and pigment bodies in newborn cells. Periphyte, cup-shaped, with 1 pyrenoid, the cells gradually mature and then disperse and fill the whole cell; 1 nucleus, many starch granules; asexual reproduction forms many zoospores, occasionally also forms iminetospores ( figure 1 ). The cell size of Chlorococcus lienyuanensis is 8-12μm, and the cells are relatively large.

[0041] 1. Environmental conditions:

[0042] The suitable growth temperature for Chlorococcum lianyuanensis is 15-30℃, and the light intensity is 10-1000μmol photons m -2 the s -1 , pH 6-10, available in CO 2 The concentration is 0-10% under the condition of aeration.

[0043] 2. Nutritional conditions:

[0044] a).NaNO 3 100-1500mg / L; b).K 2 HPO 4 ·3H 2 O10-100mg / L; c).MgSO 4 ·7...

Embodiment 2

[0052] Example 2: Lianyuan Chlorococcus treatment of domestic wastewater

[0053] 1. Wastewater source

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com