Adjustable umbrella-shaped dripping irrigation all-in-one machine

A technology of sprinkler and drip irrigation, all-in-one machine, applied in horticulture, botany equipment and methods, cultivation and other directions, can solve the problems of poor adaptability, limited irrigation range, high operating cost, and achieve a simple and reasonable design structure, easy to store and carry. , the effect of easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

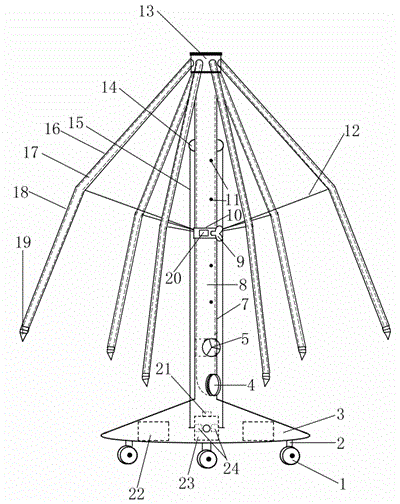

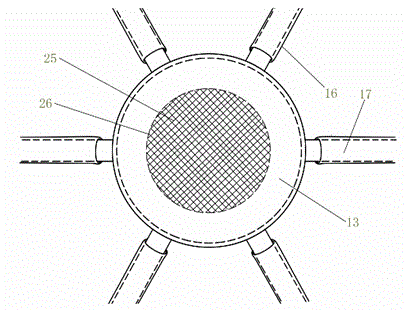

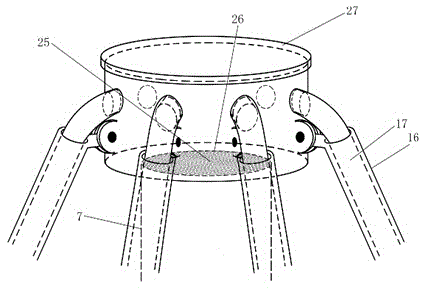

[0039] Embodiment 1: This adjustable umbrella spray and drip irrigation machine includes a chassis 3, a main rod 7, a steel ring 10, a water collection box 13, a support rod I16, a support rod II18, and a motor 24; the main rod 7 is fixed on the chassis 3 , the main rod 7 is a hollow cylinder, which is provided with a water inlet pipe 8, the water inlet 4 of the water inlet pipe 8 is opened on the lower end side of the main rod 7, the water outlet 26 of the water inlet pipe 8 is arranged on the top of the main rod 7, and the water collection box 13 is installed on the top of the main pole 7 and communicates with the water outlet 26 of the water inlet pipe 8. More than two poles I16 are installed on the water collection box 13. The poles I16 are movably connected with the water collection box 13, and one end of the pole II18 is connected to the Rod I16 is connected, the other end of the rod II18 is provided with a nozzle 19, and the inside of the rod I16 and the rod II18 is prov...

Embodiment 2

[0041] Embodiment 2: This adjustable umbrella spray and drip irrigation machine includes a chassis 3, a main rod 7, a steel ring 10, a water collection box 13, a pole I16, a pole II18, and a motor 24; the main pole 7 is fixed on the chassis 3 , the main rod 7 is a hollow cylinder, which is provided with a water inlet pipe 8, the water inlet 4 of the water inlet pipe 8 is opened on the lower end side of the main rod 7, the water outlet 26 of the water inlet pipe 8 is arranged on the top of the main rod 7, and the water collection box 13 is installed on the top of the main pole 7 and communicates with the water outlet 26 of the water inlet pipe 8. More than two poles I16 are installed on the water collection box 13. The poles I16 are movably connected with the water collection box 13, and one end of the pole II18 is connected to the Rod I16 is connected, the other end of the rod II18 is provided with a nozzle 19, and the inside of the rod I16 and the rod II18 is provided with a ...

Embodiment 3

[0043] Embodiment 3: The structure of this adjustable umbrella spray and drip irrigation all-in-one machine is the same as that of Embodiment 2, the difference is that a position sensor receiver 21 is set on the system box 23, and a position sensor transmitter 20 is set on the outside of the steel ring 10. During use, the position sensor emits device 20 issues a signal u (as Figure 8 ), which is received by the position sensor receiver 21, and the position sensor receiver 21 receives the signal u (such as Figure 8 ) changes with the change of the steel ring 10 in the position of the main rod 7, and the change of the signal u is passed as Figure 8 The shown circuit controls the positive and negative poles of the motor 24 to change the positive and negative poles of the motor so that the rotor of the motor rotates forward and reverse. Figure 8 Gradually weakens, at the highest point the signal u as Figure 8 At the weakest time, the motor 24 changes the positive and negative le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com