Method for disinfecting filtered water from water plant with cooperation between medium-pressure ultraviolet catalyzing peroxymonosulfate and chloramine

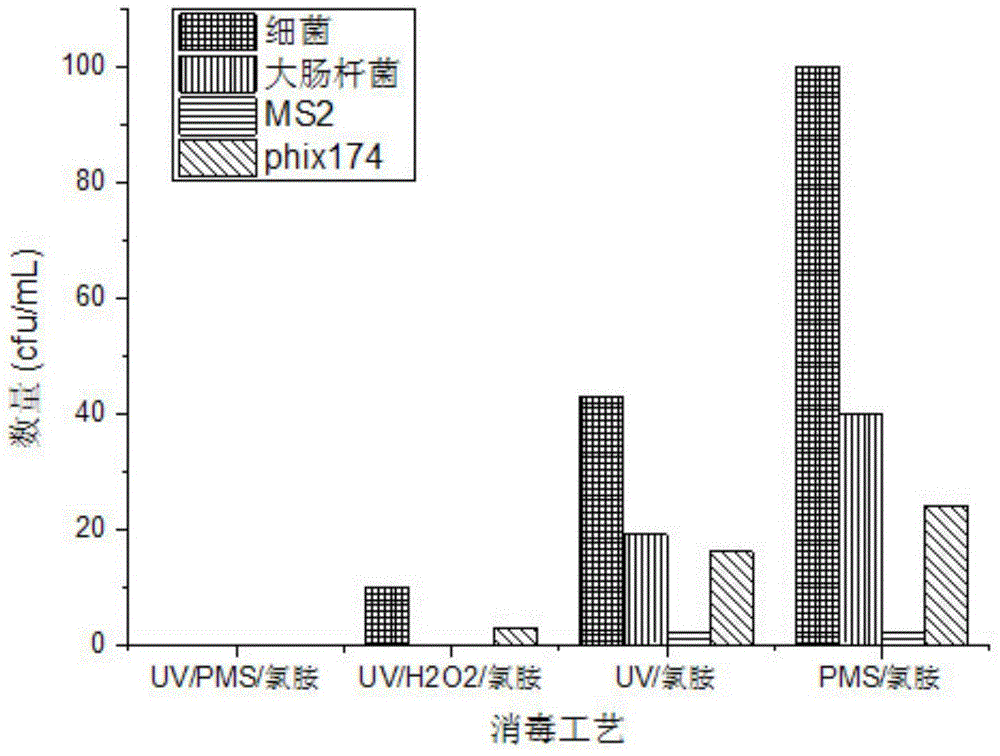

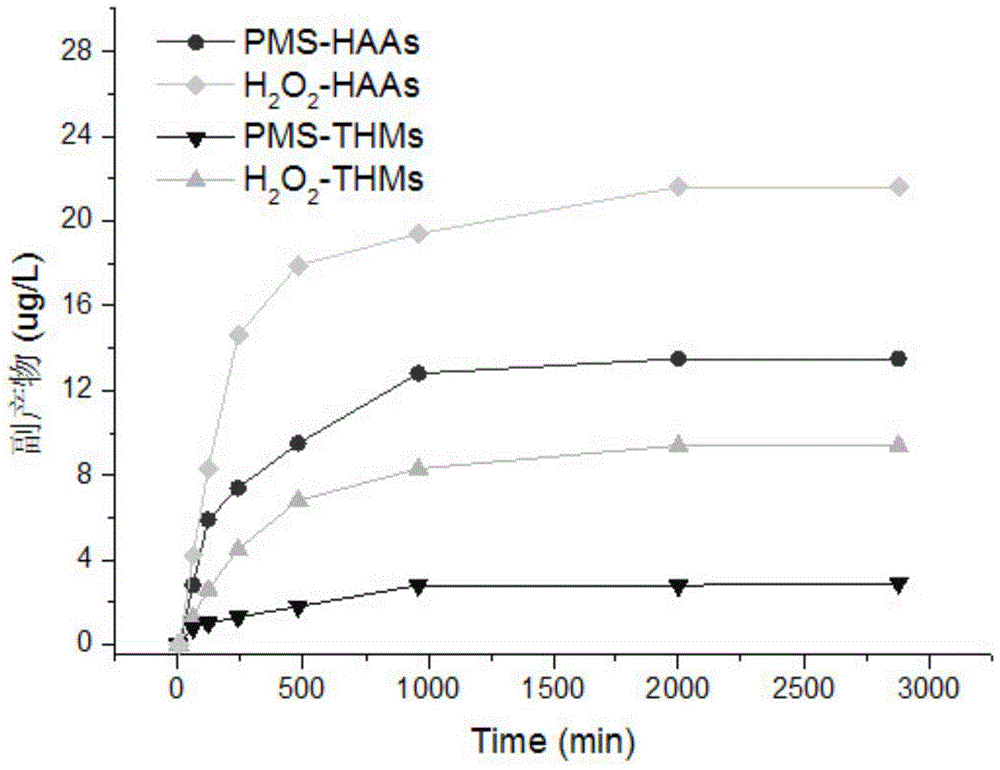

A technology of monosulfate and sulfate, which is applied in the field of medium-pressure ultraviolet disinfection enhanced by persulfate and chloramine, can solve the problem of failure to achieve effective connection of energy-saving optimization process sections, failure to ensure continuous sterilization of pipe networks, and inability to To ensure the continuous disinfection effect of the pipe network and other issues, to achieve the effect of ensuring continuous disinfection, reducing the generation of disinfection by-products, and reducing the generation of disinfection by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

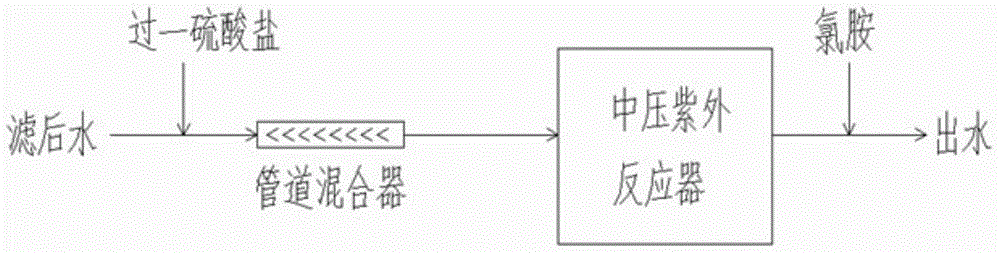

Method used

Image

Examples

Embodiment 1

[0028] Add potassium persulfate to the effluent of the water plant filter, and after mixing with a pipeline mixer, a mixed solution with a concentration of 0.2mmol / L is obtained, and the mixed solution enters a medium-pressure ultraviolet disinfection reactor for disinfection. 10mj / cm 2 , the disinfection time in the reactor is 5min, and 0.2mg / L chloramine is added at the end of the ultraviolet sterilizer, and then the effluent of the disinfection reactor is circulated in the simulated water supply pipeline for 48h, and the formation of by-products and the conditions of various bacteria and microorganisms are detected.

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is: the disinfection time in the reactor is 5min.

Embodiment 3

[0032] The difference between this example and Example 1 is that the dosing concentration of potassium persulfate is 0.4mmol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com