Phosphorus-free scale and corrosion inhibitor and preparation method thereof

A phosphorus-free scale and corrosion inhibitor technology, used in chemical instruments and methods, scale removal and water softening, water/sludge/sewage treatment, etc., can solve problems such as destroying the ecological balance of water bodies, and achieve scale and corrosion inhibition. Excellent effect, excellent scale inhibition, excellent corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

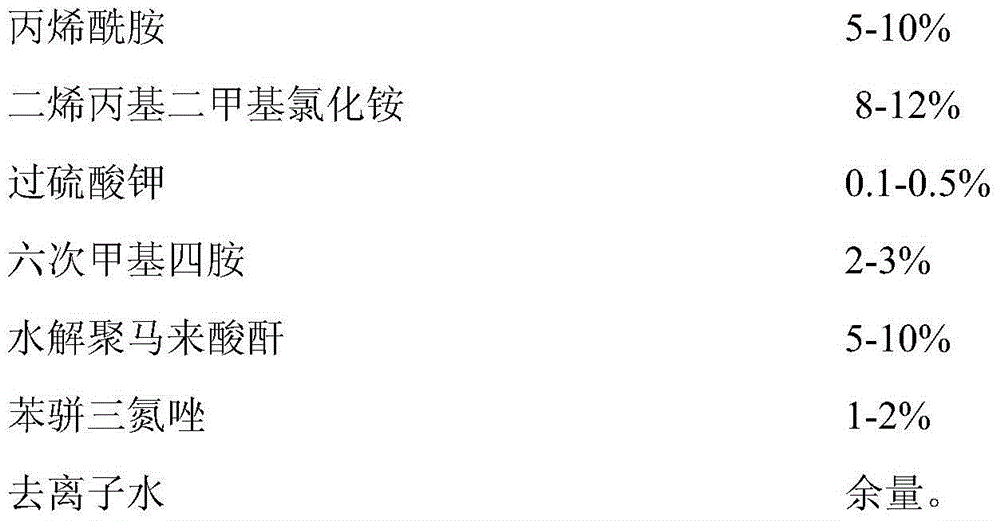

[0019] Add 50kg of acrylamide and 80kg of diallyldimethylammonium chloride into the reactor in sequence, start stirring, raise the temperature to 70°C, add 1kg of potassium persulfate in proportion, react for 3 hours, and then add 20kg of hexamethylene tetra Amine, keep warm for 2 hours, after the reaction is over, cool down to room temperature, then add 50Kg of hydrolyzed polymaleic anhydride, 10kg of benzotriazole and 789kg of deionized water in sequence, and stir for 20min to obtain the product.

Embodiment 2

[0021] Add 75kg of acrylamide and 100kg of diallyldimethylammonium chloride into the reactor in sequence, start stirring, raise the temperature to 75°C, add 2.5kg of potassium persulfate in proportion, react for 3.5 hours, and then add 25kg of hexamethylene Tetramine, keep warm for 2.5 hours, after the reaction is finished, cool down to room temperature, then add 75Kg of hydrolyzed polymaleic anhydride, 15kg of benzotriazole and 707.5kg of deionized water in sequence, and stir for 25min to obtain the product.

Embodiment 3

[0023] Add 100kg of acrylamide and 120kg of diallyldimethylammonium chloride into the reactor in sequence, start stirring, raise the temperature to 80°C, add 5kg of potassium persulfate in proportion, react for 4 hours, and then add 30kg of hexamethylene tetra Amine, keep warm for 3 hours, after the reaction is finished, cool down to room temperature, then add 100kg of hydrolyzed polymaleic anhydride, 20kg of benzotriazole and 625kg of deionized water in sequence, and stir for 30min to obtain the product.

[0024] Effect:

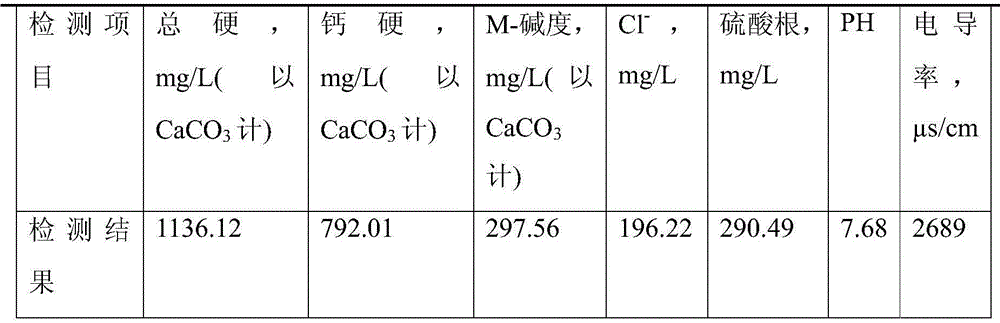

[0025] Case number one:

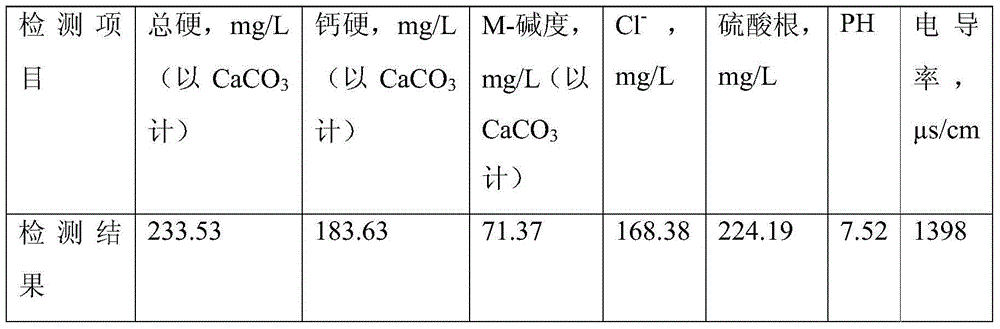

[0026] A power plant in Shenyang, Liaoning uses reclaimed water as circulating water to replenish water. The water quality analysis is shown in Table 1.

[0027] Table 1 Water quality analysis form of a power plant in Shenyang

[0028]

[0029] From the data in Table 1, it can be seen that the replenishment water of this system is of medium hardness and low alkalinity water quality. If it is operated at a higher concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com