Synthesis method of bis-piperidinyl-2-ol

A technology of bis-piperidinyl and synthesis method is applied in the field of synthesizing bis-piperidinyl-2-ol, which can solve the problems of few product varieties and limited application coverage, achieve simple and easy reaction operation, and improve anode polarization. performance, effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

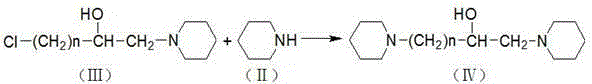

Image

Examples

Embodiment 1

[0018] In a four-necked flask equipped with a stirring device, a reflux condensing device and a thermometer, add 129 grams of benzene, add 1.1 grams of zinc chloride and 51.6 grams of piperidine, and slowly add 28 grams of chlorinated epoxypropane under stirring conditions. Reflux reaction at 80°C to 85°C for 3 hours to generate the intermediate product monopiperidinyl-2-ol, add saturated aqueous solution of potassium carbonate to the reaction mixture, then raise the temperature to 85°C to 90°C and continue the reflux reaction for 5 hours, during the reaction Use a saturated potassium carbonate aqueous solution to control the pH at 8-9 to generate bispiperidinyl-2-ol. After the reaction is completed, cool to 25-35°C, stop stirring, and let it stand. The reaction mixture is divided into two layers, and the upper layer is an organic phase. , separate and contain sediment lower layer, add water and dilute and dissolve sediment, extract twice with 51.6 grams of benzene to lower lay...

Embodiment 2

[0020] In a four-necked flask equipped with a stirring device, a reflux condensing device and a thermometer, add 120 grams of benzene, add 0.4 grams of zinc chloride, 0.32 grams of zinc hydroxide and 60 grams of piperidine, and slowly add 30 grams of chlorinated Butylene oxide, reflux at 85°C to 90°C for 4 hours to generate the intermediate product monopiperidinyl-2-ol, add 20% potassium hydroxide solution to the reaction mixture, and then raise the temperature to 90°C to 95°C to continue Reflux reaction for 3 hours. During the reaction, use 20% potassium hydroxide solution to control the pH at 8-9 to generate bispiperidinyl-2-ol. After the reaction is completed, cool to 30-40°C, stop stirring, stand still, and react The mixture is divided into two layers, the upper layer is an organic phase, and the lower layer containing the sediment is separated, and water is added to dilute and dissolve the sediment, and the diluted solution of the lower layer is extracted twice with 54 gra...

Embodiment 3

[0022] In a four-neck flask equipped with a stirring device, a reflux condensing device and a thermometer, add 134 grams of benzene, add 0.30 grams of zinc chloride, 0.22 grams of zinc hydroxide and 89 grams of piperidine, and slowly add 32 grams of chlorinated Butylene oxide, reflux at 80°C to 90°C for 3.5 hours to generate the intermediate product product monopiperidinyl-2-ol, add 20% potassium hydroxide solution to the reaction mixture, then raise the temperature to 85°C to 95°C to continue Reflux reaction for 4 hours. During the reaction, use 20% potassium hydroxide solution to control the pH at 8~9 to generate bispiperidinyl-2-ol. After the reaction is completed, cool to 20~30°C, stop stirring, stand still, and react The mixture is divided into two layers, the upper layer is an organic phase, and the lower layer containing the sediment is separated, and water is added to dilute and dissolve the sediment, and the diluted solution of the lower layer is extracted twice with 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com