High dehydration solidification pressuring bearing plugging agent

A pressure-bearing plugging agent, high water loss technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor bridging and plugging pressure-bearing capacity, affecting the strength of filter cake, insufficient strength, etc. , to improve the pressure bearing capacity, reduce the mud leakage, and increase the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The components and mass ratio of the plugging agent: 60% inorganic mineral material, 10% fiber, 8% inorganic reinforcing agent, 20% curing agent, and 2% filter aid; the inorganic mineral material is ash calcium, and the fiber is water magnesium Stone fiber: aluminum silicate ceramic fiber cotton = 1:1, inorganic reinforcing agent is white aluminum slag, curing agent is gypsum: K 2 CO 3 : NaCL=1:2:0.5, the filter aid is active calcium silicate.

[0041] The product can be obtained after each component is mixed evenly, and the above product is subjected to the following tests:

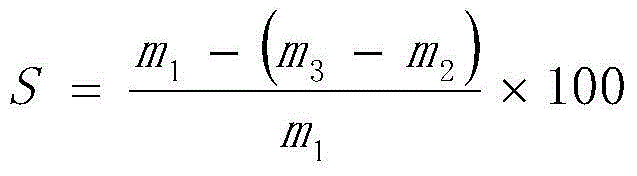

[0042] 1. Filtration time

[0043] (1) Weigh 78g of the sample (accurate to 0.01g), add it into a high stirring cup filled with 260ml of water, stir at 11000rpm for 3min, and remove the high stirring cup.

[0044] (2) Stir the sample slurry evenly and pour it into a dry and clean medium-pressure filter cup, cover the filter cover tightly, and place a 250ml beaker at the outlet of the filter to ...

Embodiment 2

[0056] The components and mass ratio of the plugging agent: 65% of inorganic mineral material, 15% of fiber, 5% of inorganic reinforcing agent, 20% of curing agent; wherein the inorganic mineral material is lime calcium: active calcium silicate = 3:1, fiber It is brucite fiber, the inorganic reinforcing agent is white aluminum slag, and the curing agent is gypsum: K 2 CO 3 : NaCl=1:2:0.5.

[0057] The product can be obtained after each component is mixed evenly, and the above product is subjected to the following tests:

[0058] 1. Filtration time

[0059] (1) Weigh 78g of the sample (accurate to 0.01g), add it into a high stirring cup filled with 260ml of water, stir at 11000rpm for 3min, and remove the high stirring cup.

[0060] (2) Stir the sample slurry evenly and pour it into a dry and clean medium-pressure filter cup, cover the filter cover tightly, and place a 250ml beaker at the outlet of the filter to receive the filtrate.

[0061] (3) Adjust the gas source to 0....

Embodiment 3

[0072] The components and mass ratio of the plugging agent: 55% inorganic mineral material, 15% fiber, 10% inorganic reinforcing agent, 15% curing agent, and 5% filter aid; the inorganic mineral material is ash calcium, and the fiber is water magnesium Stone fiber: aluminum silicate ceramic fiber cotton = 1:1; inorganic reinforcing agent is white aluminum slag, curing agent is gypsum: K 2 CO 3 : NaCL=1:2:0.5, the filter aid is light calcium carbonate.

[0073] The product can be obtained after each component is mixed evenly, and the above product is subjected to the following tests:

[0074] 1. Filtration time

[0075] (1) Weigh 78g of the sample (accurate to 0.01g), add it into a high stirring cup filled with 260ml of water, stir at 11000rpm for 3min, and remove the high stirring cup.

[0076] (2) Stir the sample slurry evenly and pour it into a dry and clean medium-pressure filter cup, cover the filter cover tightly, and place a 250ml beaker at the outlet of the filter to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com