A precision electroforming method for making microstructure of high-frequency corrugated feed horn

A feed horn and microstructure technology, which is applied in the field of precision and ultra-precision device processing, can solve the difficulty of making high-frequency corrugated feed horn microstructures, the inability to uniformly deposit non-capsulated electroforming layers, and the difficulty in processing inner corrugated microstructures. etc. to achieve uniform electroforming deposition, ensure low roughness, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The steps of preparing the high-frequency corrugated feed horn in this embodiment are as follows: Figure 7 As shown, specifically:

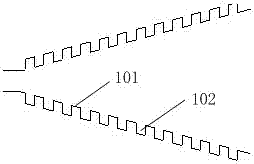

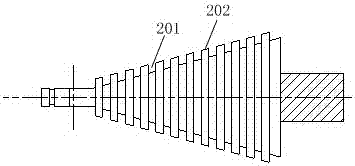

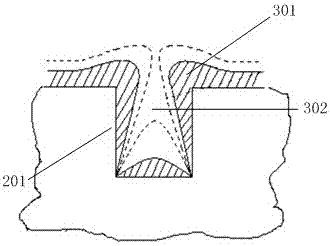

[0039] Step 1: Make the electroforming core mold of the feed speaker. Produced by machining or casting figure 1 The electroformed mandrel for the feed horn shown in figure 2 shown. in, figure 1Among them, the horn teeth 101 are 0.24mm wide, the horn grooves 102 are 0.24mm wide, the horn grooves 102 are 0.37mm deep, the number of teeth is 80, the horn input radius is 0.75mm, the output radius is 4.33mm, the total length of the horn is 47.2mm, and the corrugated feed horn frequency is 183GHz. In this embodiment, the mandrel is made of 6061 aluminum alloy material, such as figure 2 As shown, the size of the mandrel groove 201 is copied from the trumpet tooth 101, with a width of 0.24mm and a depth of 0.37mm. The size of the mandrel tooth 202 is copied from the horn groove 102, with a width of 0.24mm.

[0040] Step 2: Perform surface ...

Embodiment 2

[0055] In this embodiment, except for the size of the feed horn and the electroforming mandrel described below, and the manufacturing materials of some structures, the materials, steps and manufacturing methods of the remaining parts are the same as those of Embodiment 1, and the different parts as follows:

[0056] In step 1, create figure 1 The electroformed mandrel for the feed horn shown in , where, figure 1 The dimensions of the feed horn are as follows: the horn teeth 101 are 0.27mm wide, the horn groove 102 is 0.27mm wide, the groove depth is 0.45mm, the number of teeth is 80, the horn input radius is 2.71mm, the output radius is 20.85mm, the total length of the horn is 76.23mm, and the corrugated feed The horn frequency is 150GHz.

[0057] In this embodiment, the mandrel is made of AZ40M magnesium alloy material, such as figure 2 The size of the mandrel slot 201 shown is copied from the trumpet tooth 101, with a width of 0.27mm and a depth of 0.45mm. The size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com