Polyacid catalyst wrapped by cadmium-based polypyridine macro ring and preparation method thereof

A technology of acid catalyst and pyridine, which is applied in the field of multi-acid catalyst wrapped in cadmium-based polypyridine macrocycle and its preparation, can solve the problems of loading and other problems, and achieve the effects of simple preparation process, improved performance and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

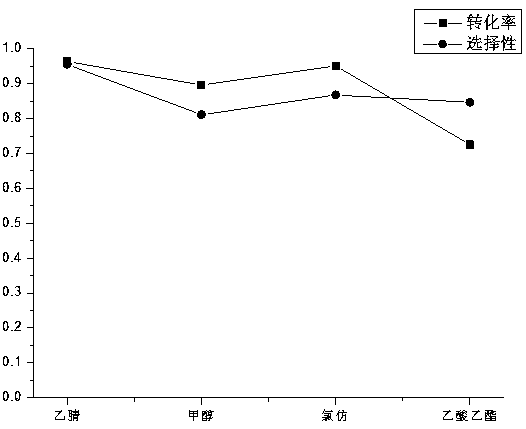

Examples

Embodiment 1

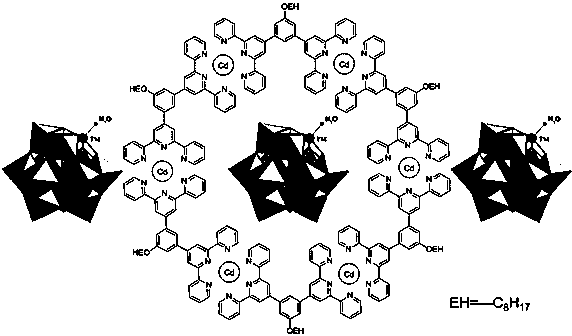

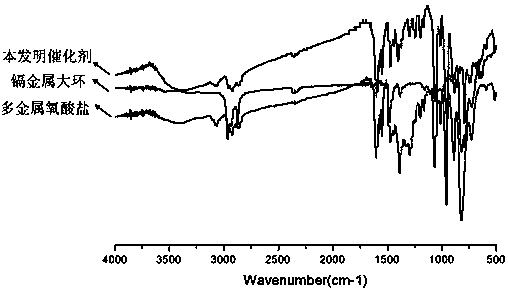

[0048] Synthesis of Quaternary Ammonium Salt of Keggin Phosphotungstic Acid Catalyst Encapsulated by Cadmium-based Polypyridine Macrocycle

[0049] Dissolve cadmium-based polypyridine macrocycle (0.008 mmol) in 10 ml of methanol and acetonitrile (1:6) mixed solvent, at the same time, [(n-C 4 h 9 ) 4 N] 4 HPW 11 M(H 2 O)O 39 (M=Ni) single transition metal substituted Keggin phosphotungstic acid quaternary ammonium salt (0.0251mmol) was dissolved in 10ml of acetonitrile to obtain acetonitrile solution of cadmium-based polypyridine macrocycle and acetonitrile solution of polyacid, under slow stirring Under normal temperature, the two solutions were mixed, stirred at room temperature for 24h, centrifuged for 10min, and the resulting solid was washed three times with acetonitrile (15ml), then twice with ethanol (10ml), and dried under natural conditions to obtain cadmium-based polypyridine Macrocyclic Nickel-Substituted Keggin Phosphotungstic Acid Catalysts. The yield is ab...

Embodiment 2

[0051] Synthesis of Quaternary Ammonium Salt of Keggin Phosphotungstic Acid Catalyst Encapsulated by Cadmium-based Polypyridine Macrocycle

[0052] Dissolve cadmium-based polypyridine macrocycle (0.0095 mmol) in 12 ml of methanol and acetonitrile (1:5) mixed solvent, at the same time, [(n-C 4 h 9 ) 4 N] 4 HPW 11 M(H 2 O)O 39 (M=Ni) single transition metal substituted Keggin phosphotungstic acid quaternary ammonium salt (0.0292mmol) was dissolved in 12ml of acetonitrile to obtain acetonitrile solution of cadmium-based polypyridine macrocycle and acetonitrile solution of polyacid, under slow stirring Under normal conditions, the two solutions were mixed, stirred at room temperature for 24 hours, and centrifuged for 12 minutes. The resulting solid was washed three times with acetonitrile (15ml), then washed twice with ethanol (10ml), and dried under natural conditions to obtain cadmium-based polypyridine Macrocyclic Nickel-Substituted Keggin Phosphotungstic Acid Catalysts....

Embodiment 3

[0054] Synthesis of Quaternary Ammonium Salt of Keggin Phosphotungstic Acid Catalyst Encapsulated by Cadmium-based Polypyridine Macrocycle

[0055] Dissolve cadmium-based polypyridine macrocycle (0.009 mmol) in 10 ml of methanol and acetonitrile (1:4) mixed solvent, at the same time, [(n-C 4 h 9 ) 4 N] 4 HPW 11 M(H 2 O)O 39 (M=Ni) single-transition metal substituted Keggin phosphotungstic acid quaternary ammonium salt (0.027mmol) was dissolved in 10ml of acetonitrile to obtain acetonitrile solution of cadmium-based polypyridine macrocycle and acetonitrile solution of polyacid, under slow stirring Under normal conditions, the two solutions were mixed, stirred at room temperature for 20 hours, centrifuged for 15 minutes, the resulting solid was washed three times with acetonitrile (20ml), and then washed twice with ethanol (10ml), and dried under natural conditions to obtain cadmium-based polypyridine Macrocyclic Nickel-Substituted Keggin Phosphotungstic Acid Catalysts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com