Activation method of graphite felt applied to cathode of Electro-Fenton system

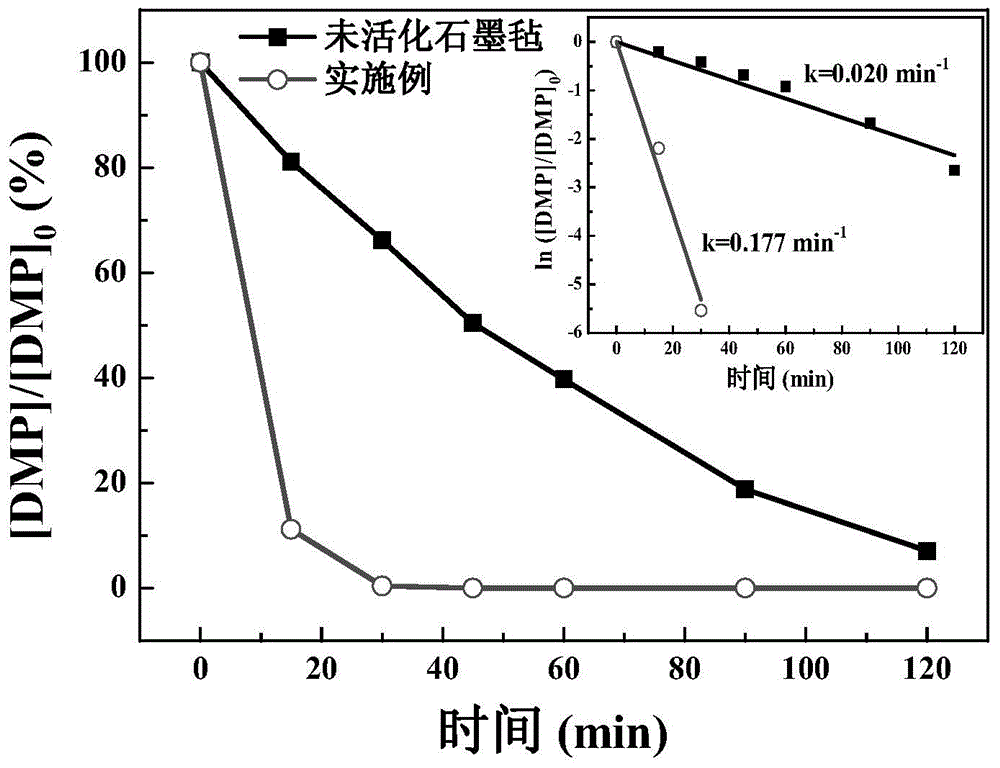

An activation method, graphite felt technology, applied in electrochemical water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of reducing material stability and service life, severe oxidation of graphite felt fiber surface, unsuitable for large-scale applications and other problems, to achieve the effect of increasing and improving reaction active sites, excellent oxygen reduction electrocatalytic activity, excellent stability and reuse performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of activated graphite felt of the present invention is as follows:

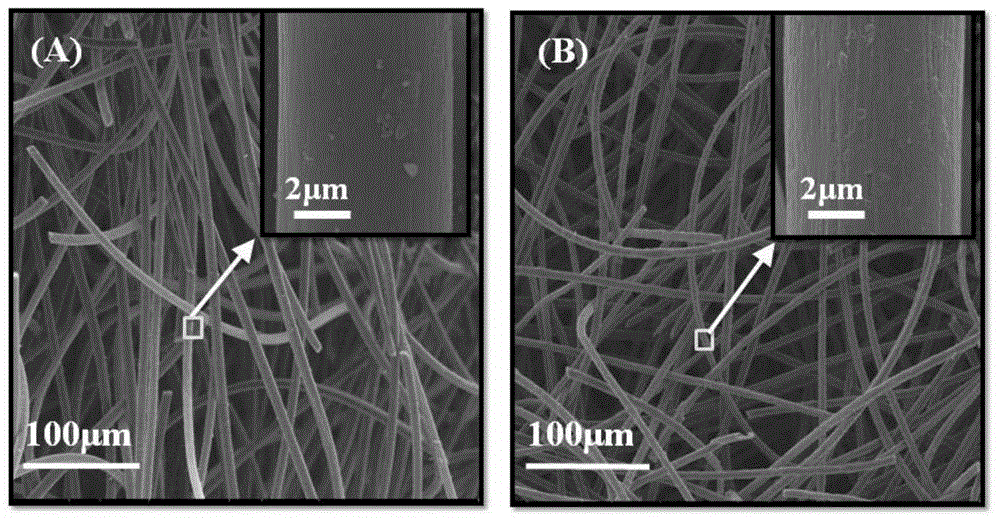

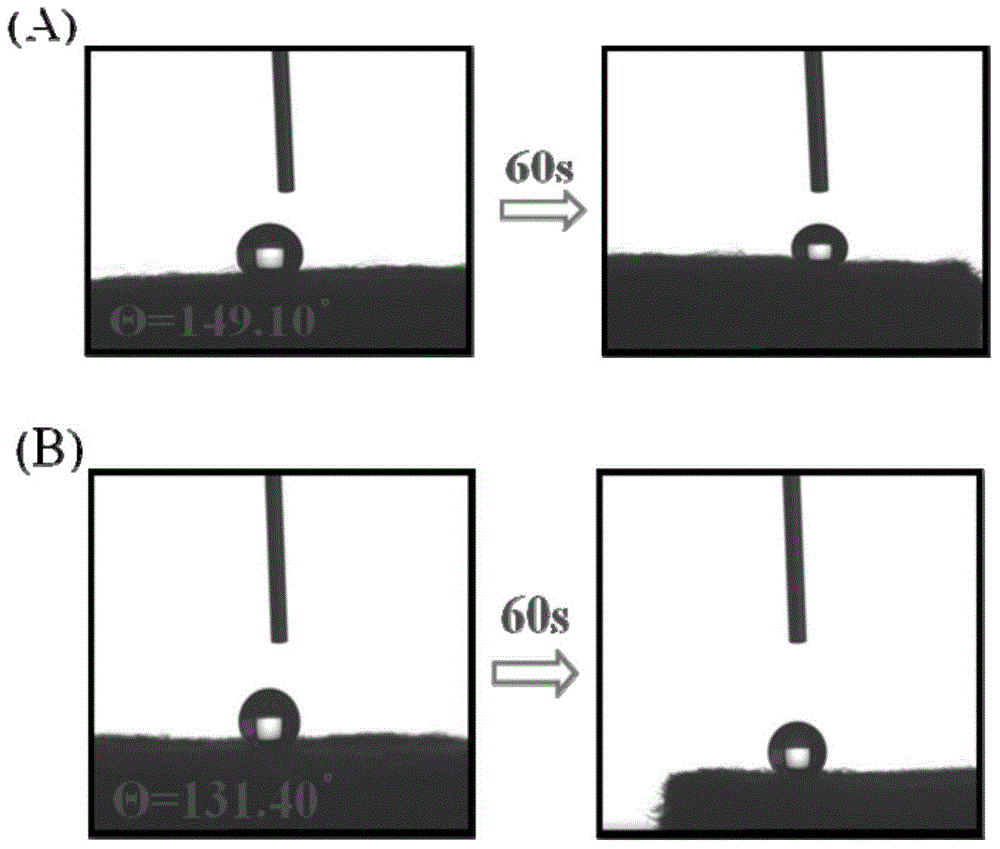

[0047] The graphite felt was soaked in acetone for 60 minutes at room temperature and ultrasonically cleaned, and then ultrasonically cleaned with deionized water to remove residual organic solvents, and dried to obtain degreasing treated graphite felt. Then soak it in an appropriate amount of 1.5mol / L KOH solution, and ultrasonically treat it for 1 hour to allow the KOH solution to fully soak the graphite felt. Heat at a constant temperature of 85°C to volatilize the solvent and precipitate KOH crystals, which are uniformly coated on the surface of the graphite felt. Put the KOH-coated graphite felt material in a high-temperature furnace, 2 Under the atmosphere protection, the temperature is raised to 900°C at 5°C / min, the temperature is kept constant for 60 minutes, and the temperature is lowered to room temperature at 10°C / min. Then soak in deionized water, and ultrasonically cl...

Embodiment 2

[0049] The preparation method of activated graphite felt of the present invention is as follows:

[0050] The graphite felt was soaked in ethanol for 30 minutes at room temperature and ultrasonically cleaned, and then ultrasonically cleaned with deionized water to remove residual organic solvents, and dried to obtain degreasing treated graphite felt. The obtained graphite felt after degreasing is immersed in an appropriate amount of 3.0 mol / L NaOH solution and ultrasonically treated for 2 hours to allow the NaOH solution to fully soak the graphite felt. Heat at a constant temperature of 85°C to volatilize the solvent and precipitate NaOH crystals, which are uniformly coated on the surface of the graphite felt. NaOH-coated graphite felt material is placed in a high-temperature furnace, 2 Under the protection of the atmosphere, the temperature is increased to 800°C at 5°C / min, the temperature is kept constant for 90 minutes, and the temperature is reduced to room temperature at 20°...

Embodiment 3

[0052] The preparation method of activated graphite felt of the present invention is as follows:

[0053] The graphite felt is immersed in a mixture solution of acetone and ethanol with a volume ratio of 1:1, ultrasonically cleaned at room temperature for 60 minutes, ultrasonically cleaned with deionized water to remove residual organic solvents, and dried to obtain degreasing treated graphite felt. The obtained graphite felt after degreasing is immersed in an appropriate amount of 4.0 mol / L KOH solution and ultrasonically treated for 2 hours to allow the KOH solution to fully soak the graphite felt. Heat at a constant temperature of 85°C to volatilize the solvent and precipitate KOH crystals, which are uniformly coated on the surface of the graphite felt. The obtained KOH-coated graphite felt material is placed in a high-temperature furnace, and under the protection of an inert atmosphere, the temperature is raised to 700° C. at 10° C. / min, and the temperature is kept constant f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com