A kind of dye-sensitized solar cell photoanode and preparation method thereof

A solar cell and dye sensitization technology, which is applied in the field of dye-sensitized solar cell photoanode and its preparation, can solve problems such as open circuit voltage loss, achieve the effect of inhibiting charge recombination and reducing dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

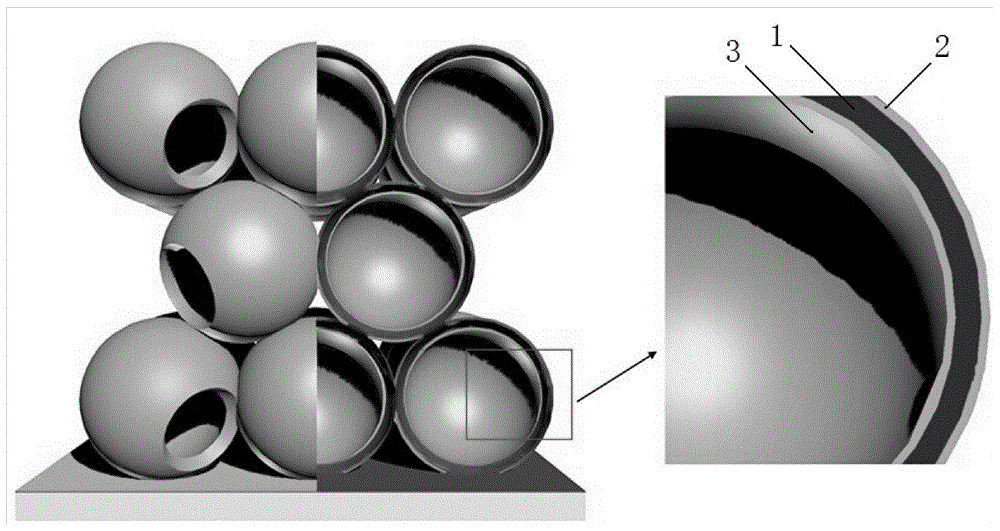

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of photoanode of dye-sensitized solar cell, its concrete steps are:

[0039] (1) Add SnCl to the glass bottle 2 2H 2 O2 2.85 mg, ammonium fluoride 4.50 mg, polystyrene (PS) microsphere suspension (diameter 300 nm) 275 μl, polyethylene glycol 60 μl (molecular weight 200), the resulting mixture was ultrasonicated for 2 hours, and mixed uniformly;

[0040] (2) Take 45 μl of the mixture from the suspension obtained above and drop it on the FTO conductive glass to form a transparent conductive oxide film with a thickness of 10 μm, and use scotch tape to define the electrode area as 1.0*1.0cm 2 ;

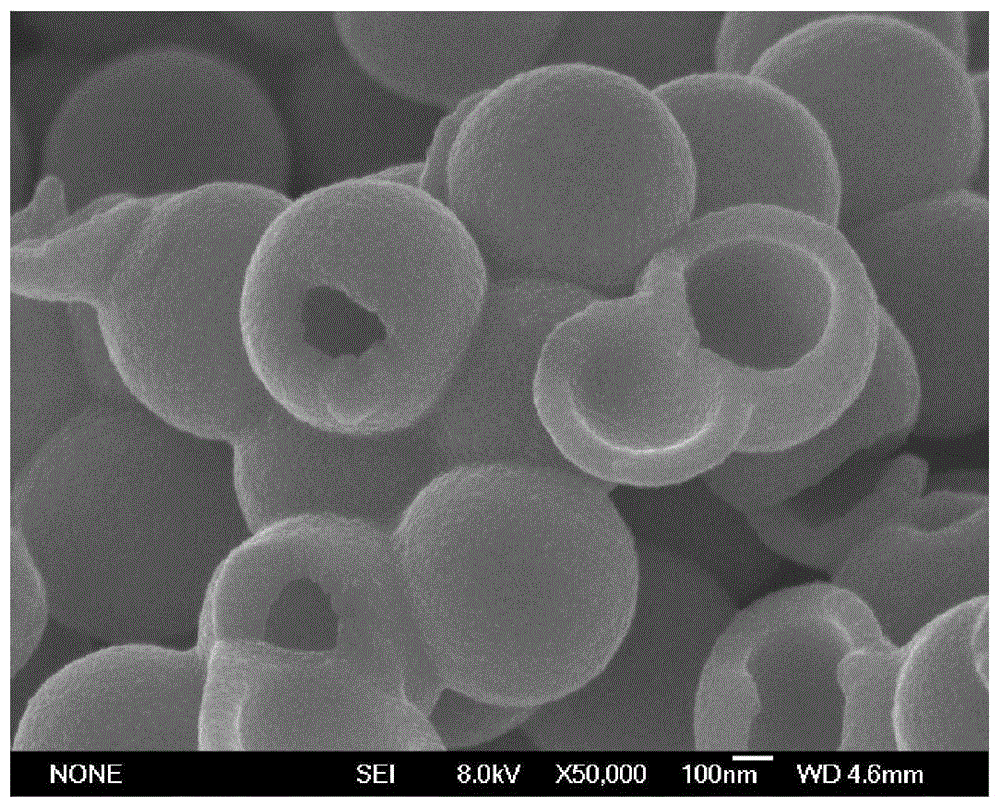

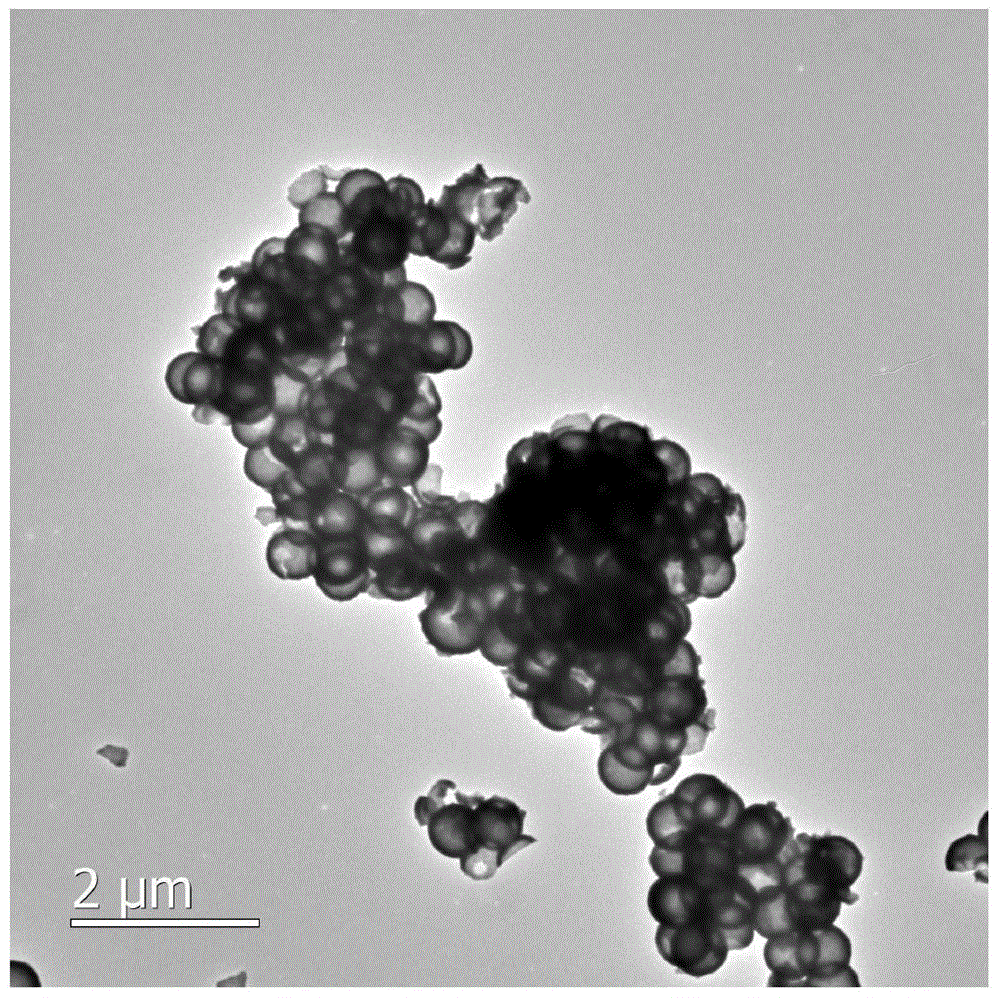

[0041] (3) The obtained electrode was dried overnight at room temperature and then placed in a muffle furnace. After rising from room temperature to 450°C, it was kept for 2 hours to completely remove the PS template to obtain a three-dimensional transparent conductive oxide hollow sphere electrode; the heating rate was 1°C / Minute;

[0042] (4) hea...

Embodiment 2

[0045] (1) Add 41.63 mg of tert-butoxide tin (IV), 4.50 mg of ammonium fluoride and 275 μl of polystyrene (PS) microsphere suspension (diameter 600 nm), 60 μl of polyethylene glycol (molecular weight 800 ), the resulting mixture was ultrasonicated for 2 hours and mixed uniformly;

[0046] (2) Take 40 μl of the mixture from the suspension obtained above and drop it on the FTO conductive glass to form a transparent conductive oxide film with a thickness of 10 μm, and use scotch tape to define the electrode area as 1.0*1.0cm 2 ;

[0047] (3) The obtained electrode was dried overnight at room temperature and then placed in a muffle furnace. After rising from room temperature to 450°C, it was kept for 2 hours to completely remove the PS template to obtain a three-dimensional transparent conductive oxide hollow sphere electrode; the heating rate was 1°C / Minute;

[0048] (4) heat-treating the obtained electrode in argon for 30 minutes to improve electrical conductivity, and the he...

Embodiment 3

[0051] (1) Add Zn(Ac) to the glass bottle 2 2H 2 O13.83mg, anhydrous AlCl 3 1. 20mg and polystyrene (PS) microsphere suspension (diameter 526nm) 275μl, polyethylene glycol 60μl (molecular weight 200), the resulting mixture was ultrasonicated for 2 hours, and mixed uniformly;

[0052] (2) Take 40 μl of the mixture from the suspension obtained above and drop it on the FTO conductive glass to form a transparent conductive oxide film with a thickness of 10 μm, and use scotch tape to define the electrode area as 1.0*1.0cm 2 ;

[0053] (3) The obtained electrode was dried overnight at room temperature and then placed in a muffle furnace. After rising from room temperature to 450°C, it was kept for 2 hours to completely remove the PS template and form a transparent conductive oxide film with a thickness of 10 μm, which was defined with scotch tape The electrode area is 1.0*1.0cm 2 ;The heating rate is 1°C / min;

[0054] (4) heat-treating the obtained electrode in argon for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com