Non-aqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolytes, secondary batteries, etc., can solve the problems of gas escape, battery performance degradation, acceleration, etc., to achieve impact stability, deformation resistance strength The effect of improving and excellent high temperature cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

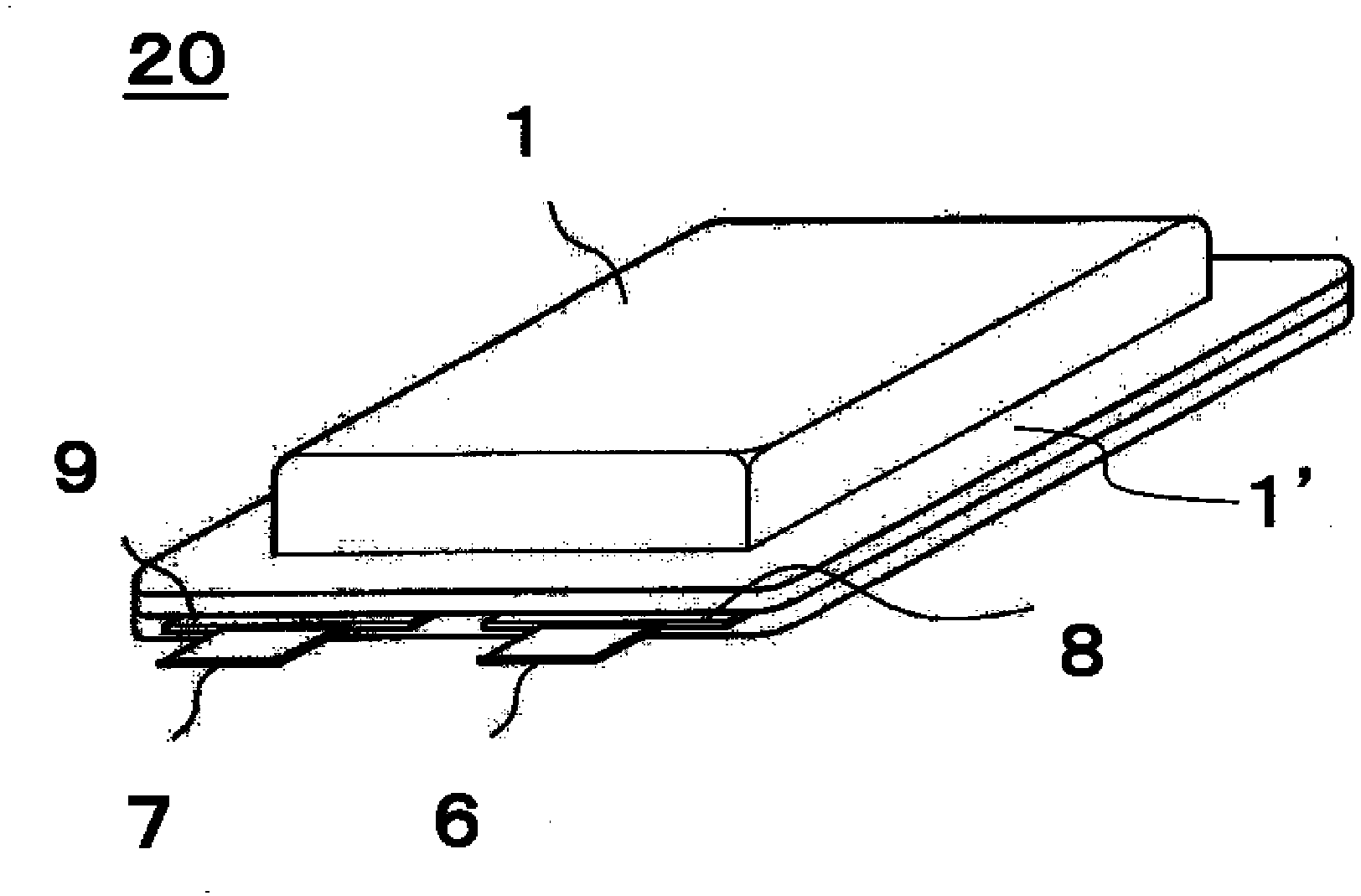

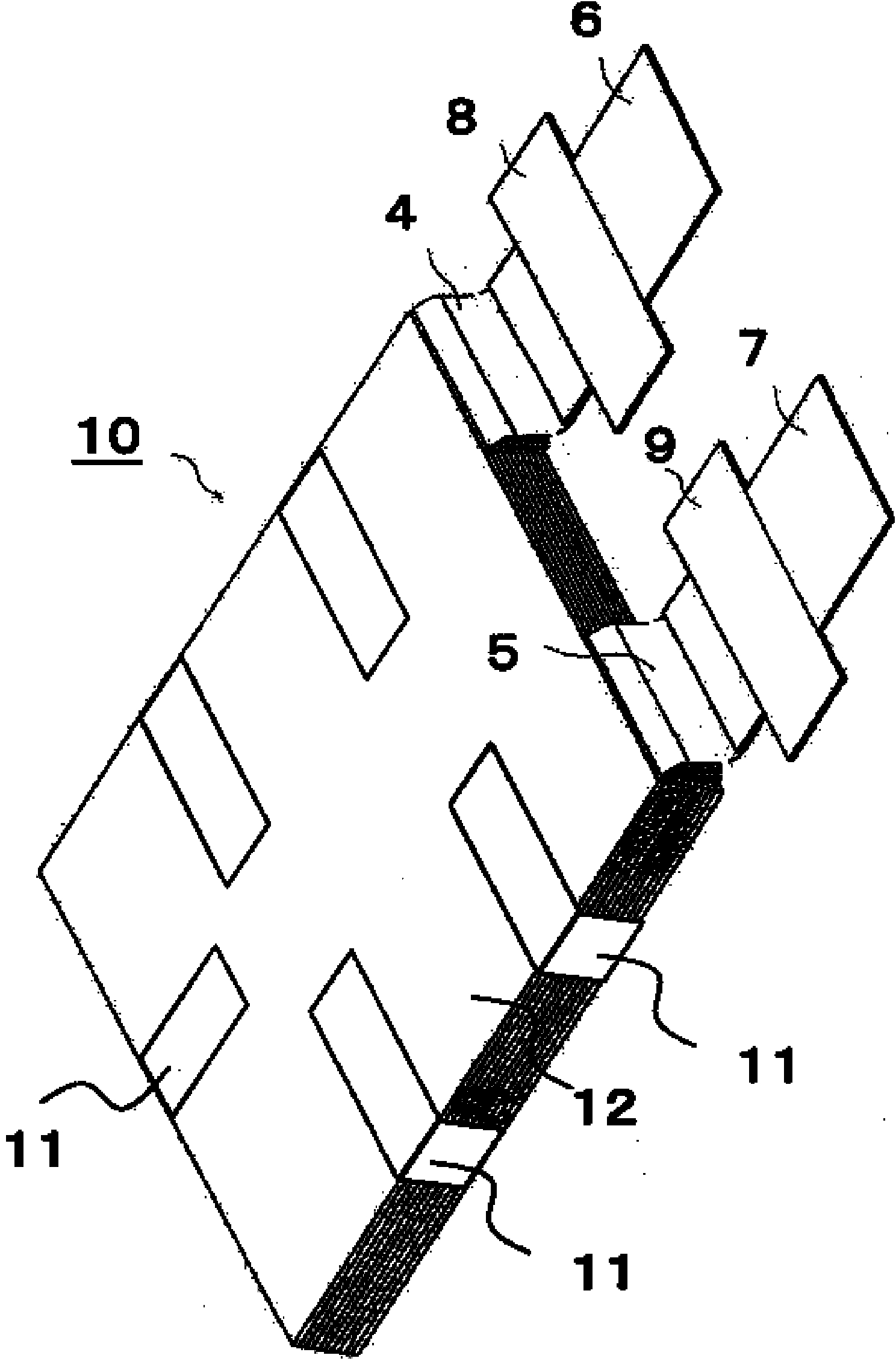

Embodiment 1

[0039]

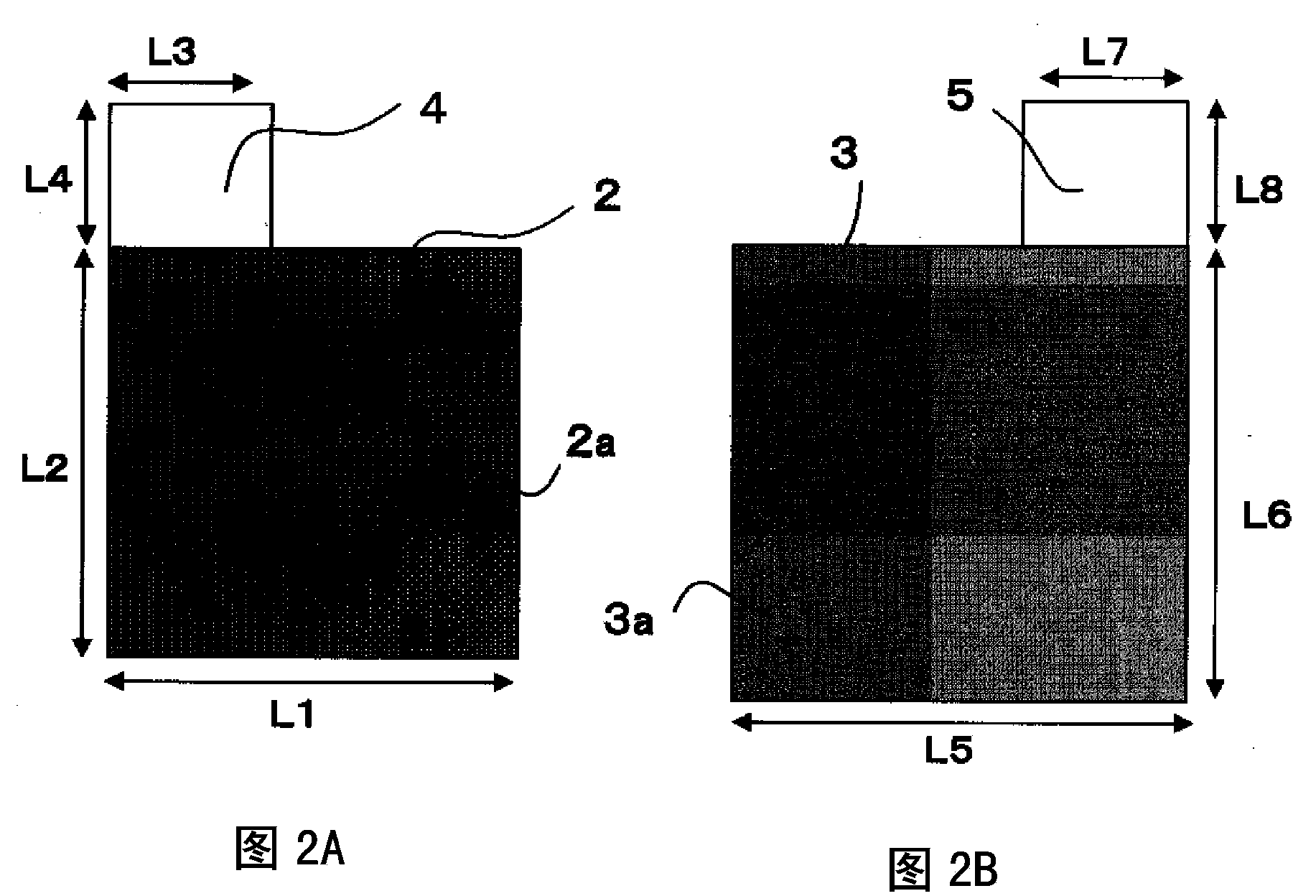

[0040] 94% by mass of Li as the positive electrode active material 1.10 (Ni 0.3 co 0.4 mn 0.3 )O 2 , 3% by mass of carbon black as a conductive agent, 3% by mass of polyvinylidene fluoride (PVdF) as a binder, and a solution of N-methyl-2-pyrrolidone (NMP) as a solvent to prepare Positive electrode mixed slurry. This positive electrode mixed slurry was coated on both surfaces of an aluminum foil (thickness: 20 μm) serving as a positive electrode core by a doctor blade method. Then, remove the solvent by heating, compress with a roller to a thickness of 0.2mm, and then, as Figure 2A As shown, cutting was performed so that the width would be L1 = 150 mm, and the height would be L2 = 150 mm, to manufacture a positive electrode plate 2 having positive electrode active material layers 2 a on both surfaces. At this time, the positive electrode core body without the positive electrode active material layer 2a protruding from the end of the positive electrode plate 2 ...

Embodiment 2

[0054] As a non-aqueous electrolyte, LiPF was dissolved at a concentration of 1.2 mol / L in a non-aqueous solvent in which EC and DEC were mixed at a volume ratio of 20:80. 6 , and added a non-aqueous electrolytic solution of 3.0% by mass of VC relative to the non-aqueous solvent, a lithium-ion battery was manufactured in the same manner as in Example 1, as a lithium-ion battery of Example 2.

Embodiment 3

[0056] As a non-aqueous electrolyte, LiPF was dissolved at a concentration of 1.2 mol / L in a non-aqueous solvent in which EC, DEC, and methyl ethyl carbonate (MEC) were mixed at a volume ratio of 30:49:21. 6 , and a non-aqueous electrolytic solution with 3.0% by mass of VC relative to the non-aqueous solvent was added, and a lithium ion battery was manufactured in the same manner as in Example 1, as a lithium ion battery of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com