Device and method for separating and purifying mixed gas of sulfur hexafluoride and nitrogen

A mixed gas and purification technology, applied in separation methods, chemical instruments and methods, sulfur and halogen compounds, etc., can solve the problems that the gas cannot be recycled and the mixed gas cannot be separated, and achieves strong practicability and device structure. The effect of reasonable and widespread promotion of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

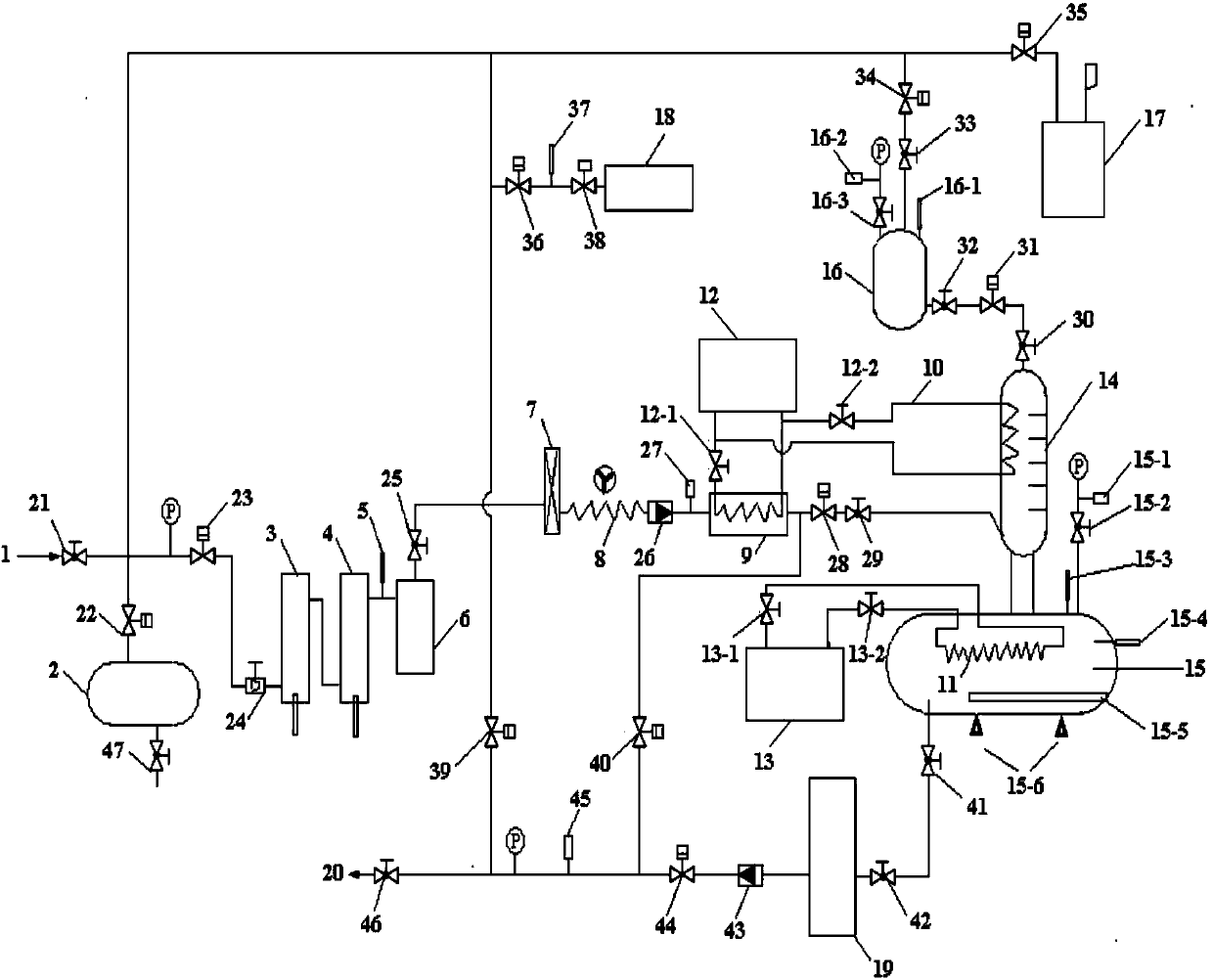

[0021] Specific implementation mode one: combine figure 1 , this embodiment is a separation and purification treatment device for sulfur hexafluoride and nitrogen mixed gas, which consists of a mixed gas inlet pipe 1, a primary dryer 3, a secondary dryer 4, a first pressure sensor 5, and a mesh filter 6 , compressor 7, air cooler 8, first heat exchanger 9 of -40°C refrigeration unit 12, second heat exchanger 10 of -40°C refrigeration unit 12, third heat exchanger of -80°C refrigeration unit 13 11. Rectification tower 14, purification tank 15, second buffer tank 16, liquid filling machine 19 and gas outlet pipe 20; mixed gas inlet pipe 1 and manual ball valve C 1 The inlet port of 21 is connected, the manual ball valve C 1 The outlet port of 21 is connected with the solenoid valve V 2 23 inlet port is connected to the manual ball valve C 1 21 with solenoid valve V 2 There is a pressure gauge between 23, solenoid valve V 2 The outlet port of 23 and the regulator valve F 1 ...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solenoid valve V 7 34 outlet port and solenoid valve V 9 The inlet port of 39 is respectively connected with the solenoid valve V 10 The inlet port of 35 is connected, the solenoid valve V 10 The outlet end of 35 is connected with lye tank 17; Described lye tank 17 is PVC material, and volume is 60L, and interior dress 5% sodium hydroxide solution. Others are the same as in the first embodiment.

[0028] The lye tank 17 is used for the absorption of harmful substances in the gas when the gas is discharged.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solenoid valve V 7 34 outlet port and solenoid valve V 9 The inlet port of 39 is respectively connected with the solenoid valve V 8 One end of 36 is connected, the solenoid valve V 8 The other end of 36 and angle solenoid valve A 1 One end of 38 is connected to the solenoid valve V 8 36 and angle solenoid valve A 1 A vacuum pressure sensor 37 is arranged between 38, and the angle solenoid valve A 1 The other end of 38 is connected with the vacuum pump 18; the vacuum pump 18 is a two-stage rotary vane type with an oil return solenoid valve, the ultimate vacuum degree is less than 0.05Pa, and the flow rate is greater than 60m 3 / h. Others are the same as in the first or second embodiment.

[0030] The vacuum pump (18) is used to evacuate the steel cylinder and the system in the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com