Gas absorption tower and application method thereof

A gas absorption and liquid absorption technology, applied in the process field, can solve the problems of unsatisfactory gas-liquid dispersion effect, affecting the production efficiency of bubble tower, and small gas-liquid phase contact area, etc., to achieve uniform size, simple structure, increase gas The effect of liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

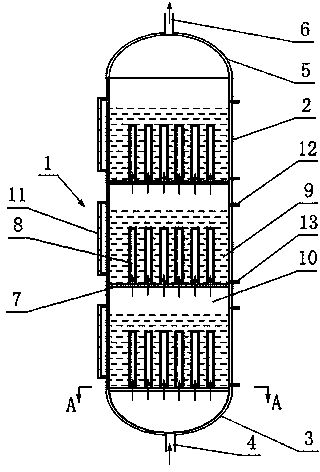

[0047] Such as Figure 1-2 As shown, the gas absorption tower of the present invention is provided with three groups of gas absorption devices 1, and the three groups of gas absorption devices 1 share the tower body 2, and the tower body 2 is vertically cylindrically arranged, and the tower body 2 and the three groups of gas absorption devices 1 all adopt Made of stainless steel;

[0048] The upper and lower sides of the tower body 2 are respectively provided with an upper tower cover 5 and a lower tower cover 3, a gas inlet 4 is provided on the lower tower cover 3, and a gas outlet 6 is provided on the upper tower cover 5;

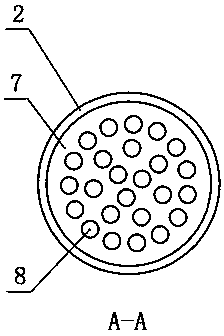

[0049] The gas absorption device 1 has an orifice 7 and more than three gas absorption pipes 8; the orifice 7 is a circular plate with mounting holes, which is horizontally arranged in the tower body 2 and fixedly connected with the inner wall of the tower body 2, so that the orifice plate 7 Divide the gas absorption device 1 into two parts, namely the g...

Embodiment 1

[0060] Gas to be absorbed: SO 2 Exhaust gas, 2000mg / m 3 .

[0061] Absorbing solution: 10-30% NaOH solution.

[0062] Gas absorption tower: made of stainless steel; the tower body is vertical, the height is 2100mm, and the tower body diameter is 1000mm; there are three sets of gas absorption devices in the tower body, each with a separate liquid level gauge, liquid replenishment port and emptying port ; 25 gas absorption tubes, 500mm high, 0.05μm absorption hole diameter.

[0063] Implementation process: pressurized, cooled SO 2 The exhaust gas continuously enters the gas absorption tower, and is respectively contacted with NaOH solution in the lower, middle and upper gas absorption devices for gas absorption, and the clean gas after three-stage gas absorption is discharged into the atmosphere.

[0064] Implementation results: SO in gas outlet exhaust 2 ≤68mg / m 3 , to meet environmental protection emission requirements.

Embodiment approach 2

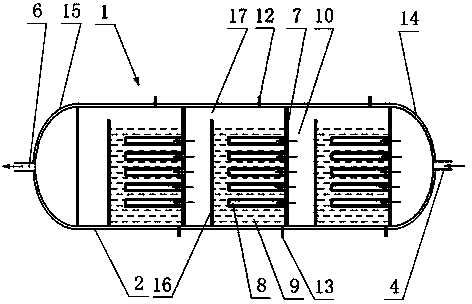

[0066] Such as image 3 As shown, the gas absorption tower of the present invention is provided with three groups of gas absorption devices 1, and the three groups of gas absorption devices 1 share the tower body 2, and the tower body 2 is vertically cylindrically arranged;

[0067] A left tower cover 15 and a right tower cover 14 are respectively provided on the left and right sides of the tower body 2, a gas inlet 4 is provided on the right tower cover 14, and a gas outlet 6 is provided on the left tower cover 15;

[0068] The gas absorption device 1 has an orifice plate 7 and more than three gas absorption pipes 8; the orifice plate 7 is a circular plate with installation holes, which is vertically arranged in the tower body 2, and is fixedly connected with the inner wall of the tower body 2 in the form of sealing welding The gas absorption tube 8 has a single-ended opening, and its open end is sealed and fixed on the mounting hole of the orifice plate 7 by means of sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com