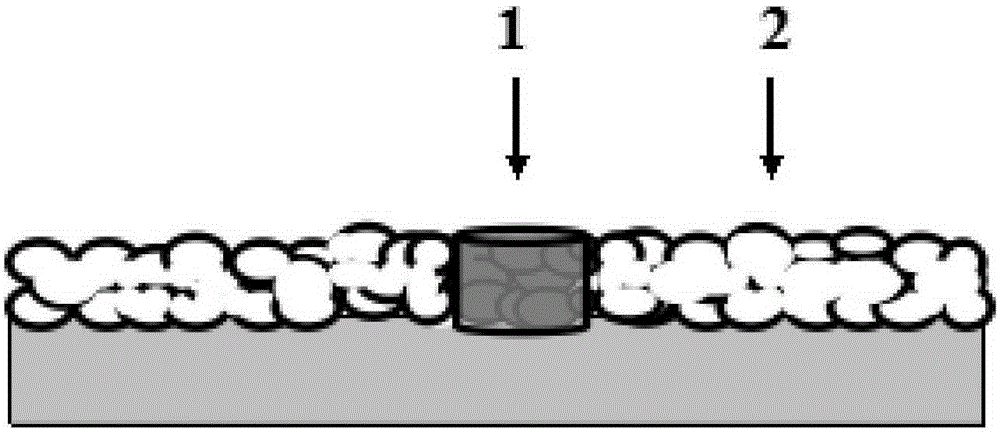

Superhydrophilic microwell sensing interface for enrichment and trace detection and its preparation method

A sensing interface and super-hydrophilic technology, applied in chemical instruments and methods, laboratory containers, color/spectral characteristic measurement, etc., can solve the problems of real-time tracking of difficult-to-target micro-droplets and easy rolling of droplets, etc. Achieve the effects of pollution-free preparation process, low cost, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

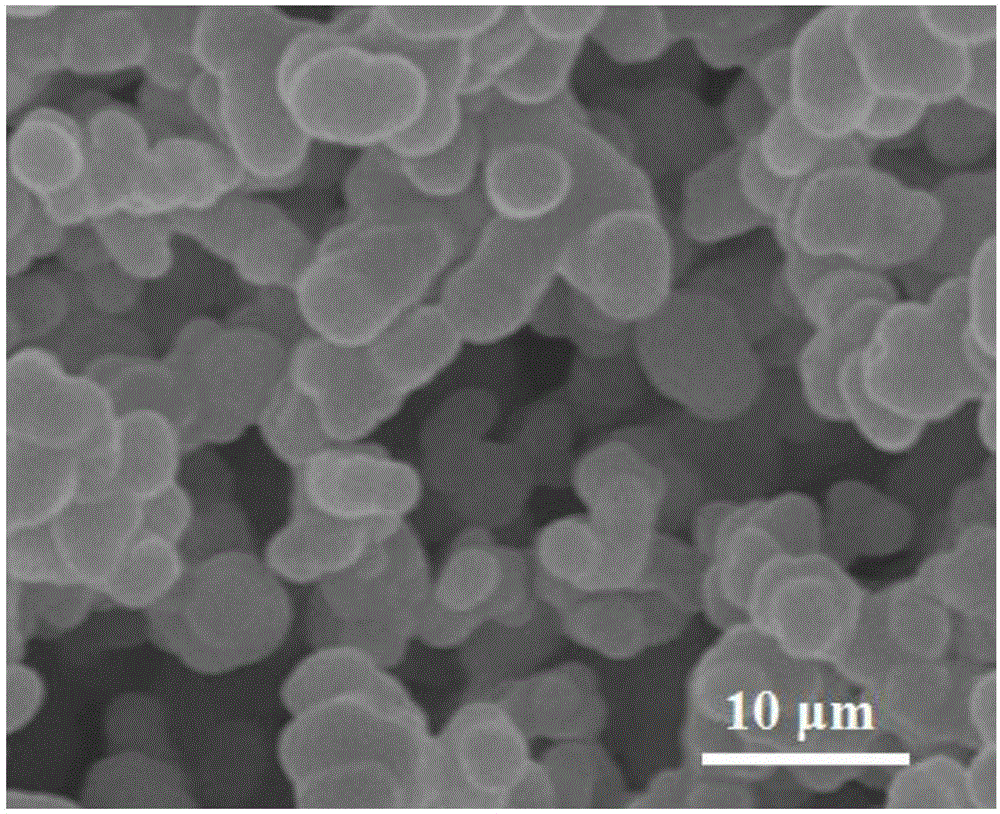

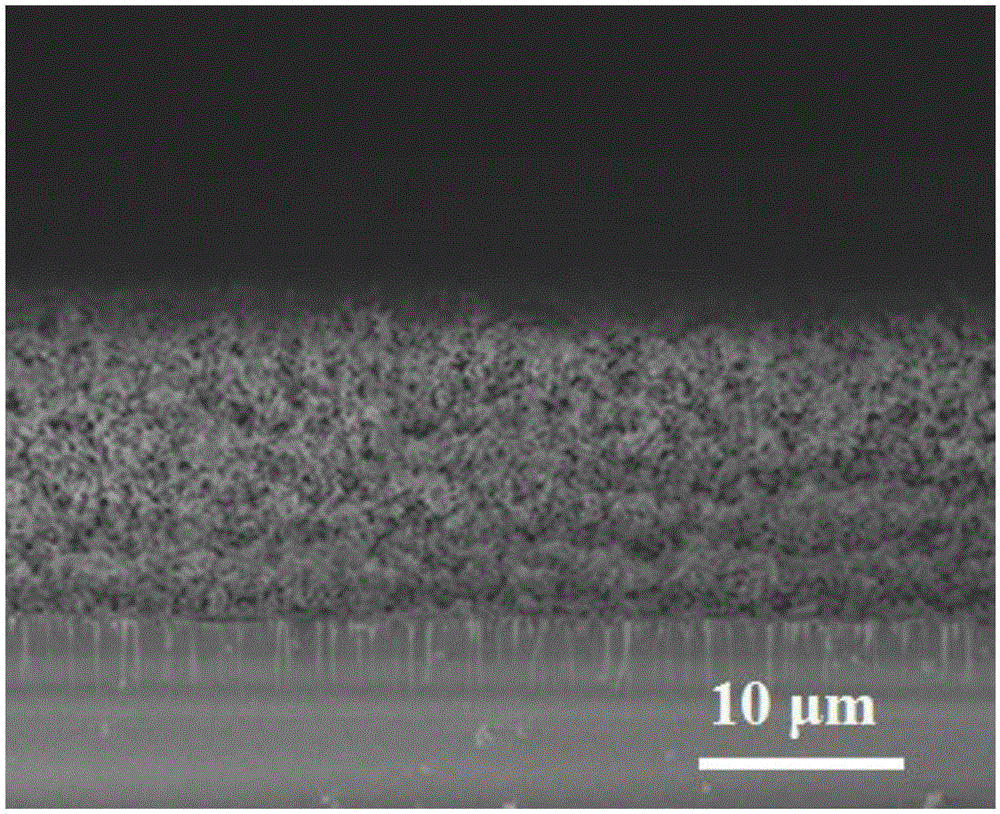

[0031] (1) Soak 2×1 square centimeter glass pieces in hot Piranha solution (98% concentrated sulfuric acid / 30% hydrogen peroxide, V / V=7:3) for 1 hour. After cooling, ultrasonically clean with acetone, ethanol, and deionized water for 10 minutes, respectively. Finally, blow it off with nitrogen and dry it in a drying oven; light the candle (avoid using the wax head for new candles, and do not use the wax tail for too short candles). After the flame is stable, use tweezers to pick up the clean glass piece at a constant speed ( 2cm / s) over the stable burning flame and repeatedly translate 7 times, the glass surface will physically deposit a layer of uniformly distributed carbon nanoparticles with a thickness of about 10 microns. Take 2 milliliters of tetraethoxysilane and 2 milliliters of ammonia water in a small beaker of 5 milliliters respectively, then put the glass sheet deposited with carbon nanoparticles and the two small beakers into a desiccator respectively, and place th...

Embodiment 2

[0040] (1) Soak a 2×1 square centimeter quartz plate in hot Piranha solution (98% concentrated sulfuric acid / 30% hydrogen peroxide, V / V=7:3) for 1 hour. After cooling, ultrasonically clean with acetone, ethanol, and deionized water for 10 minutes, respectively. Finally, blow it off with nitrogen and dry it in a drying oven; light a candle (avoid using a wax head for a new candle, and do not use a wax tail for a candle that is too short), and after the flame is stable, use tweezers to pick up a clean quartz piece at a constant speed ( 2cm / s) over the stable burning flame and repeatedly translate 7 times, the surface of the quartz plate will physically deposit a layer of uniformly distributed carbon nanoparticles with a thickness of about 10 microns. Take 2 milliliters of tetraethoxysilane and 2 milliliters of ammonia water in a small beaker of 5 milliliters respectively, then put the quartz sheet with deposited carbon nanoparticles and two small beakers into a desiccator respec...

Embodiment 3

[0049] (1) Soak 2×1 square centimeter silicon wafers in hot Piranha solution (98% concentrated sulfuric acid / 30% hydrogen peroxide, V / V=7:3) for 1 hour. After cooling, ultrasonically clean with acetone, ethanol, and deionized water for 10 minutes, respectively. Finally, blow it off with nitrogen and dry it in a drying oven; light a candle (avoid using a wax head for a new candle, and do not use a wax tail for a candle that is too short), and after the flame is stable, use tweezers to pick up a clean silicon wafer at a constant speed ( 2cm / s) over the stable burning flame and repeatedly translate 7 times, the surface of the silicon wafer will physically deposit a layer of uniformly distributed carbon nanoparticles with a thickness of about 10 microns. Take 2 milliliters of tetraethoxysilane and 2 milliliters of ammonia water in a small beaker of 5 milliliters respectively, then put the silicon wafer and two small beakers deposited with carbon nanoparticles into a desiccator res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com