Production method of nickel paste for ultrahigh-capacitance MLCC (multilayer ceramic capacitor), nickel paste and MLCC

A production method and ultra-high-capacity technology are applied to the dispersion of nickel paste for ultra-high-capacity MLCC, MLCC. In the field, it can solve the problems of pressure resistance, poor HALT performance, and high-capacity nickel paste cannot achieve the dispersion effect, and achieve the effects of good pressure resistance, improved dispersion effect, and HALT performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

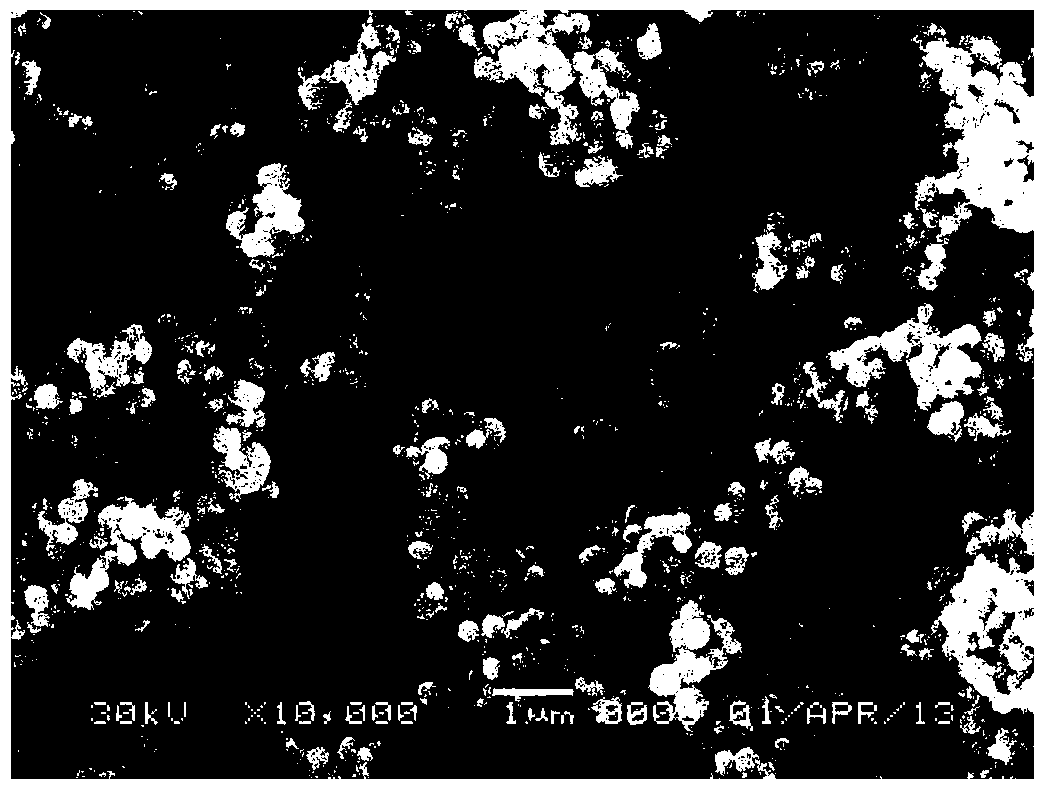

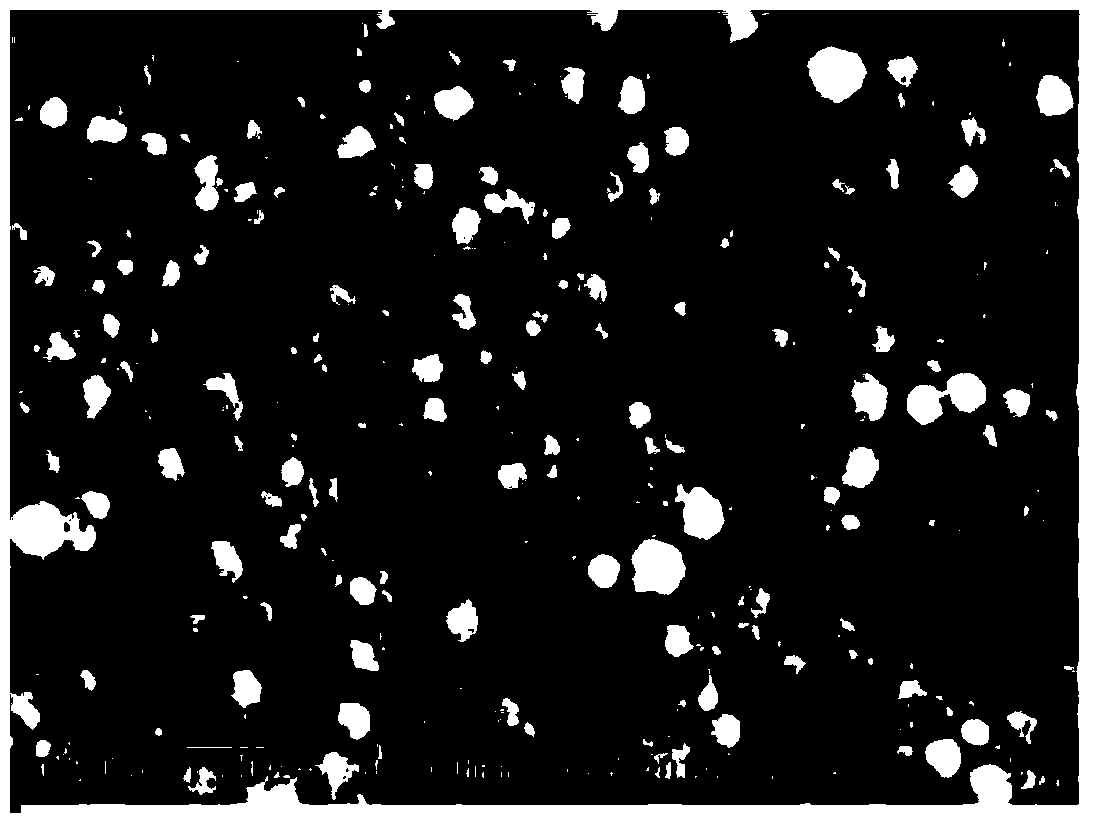

Image

Examples

Embodiment 1

[0030] Make nickel paste for ultra-high capacity MLCC as follows:

[0031] (1) Take 40 parts by weight of nickel powder, 0.3 parts of phosphate ester dispersant Hostaphat OPS 75E and 59.7 parts of dodecane, place them in a sand mill, and disperse at 1500 rpm for 2 hours.

[0032] (2) Get 40 parts by weight of barium titanate powder, 0.3 parts of phosphoric acid ester dispersant Hostaphat OPS 75E and 59.7 parts of dodecane; here, the total weight of barium titanate powder, dispersant and dodecane 10% of the total weight of the material in step (1). The material was placed in a sand mill and dispersed at 1500rpm for 2 hours.

[0033] (3) Mix the materials of steps (1) and (2), and add the binder to stir; wherein the preparation method of the binder is: dissolve the ethyl cellulose resin with dodecane, and make the ethyl cellulose The concentration (w / v) is 8%. The add-on of binding agent is 20% of step (1) material gross weight.

[0034] (4) Grinding and dispersing with a th...

Embodiment 2

[0037] Make nickel paste for ultra-high capacity MLCC as follows:

[0038] (1) Get 55 parts of nickel powder by weight, 0.5 part of phosphoric acid ester dispersant Hostaphat OPS 75E, 0.5 part of Span series dispersant S-40, 22 parts of octanol, 22 parts of terpineol, place In a sand mill, disperse at 2000 rpm for 2.5 hours.

[0039] (2) 51 parts of barium titanate powder, 0.5 parts of phosphate ester dispersant Hostaphat OPS75E, 0.5 parts of Span series dispersant S-40, 24 parts of octanol, and 24 parts of terpineol are taken by weight; The total weight of material at place is 20% of the total weight of material in step (1). The material was placed in a sand mill and dispersed at 2000rpm for 2.5 hours.

[0040] (3) Mix the materials of steps (1) and (2), and add the binder to stir; wherein the preparation method of the binder is: dissolve the ethyl cellulose resin with octanol to make the ethyl cellulose The concentration (w / v) was 15%. The add-on of binder is 30% of step...

Embodiment 3

[0044] Make nickel paste for ultra-high capacity MLCC as follows:

[0045] (1) Take 70 parts by weight of nickel powder, 2 parts of lecithin, and 28 parts of menthol, place them in a sand mill, and disperse at 2500 rpm for 1.5 hours.

[0046] (2) Take 70 parts by weight of barium titanate powder, 2 parts of lecithin, and 28 parts of menthol; the total weight of barium titanate powder, lecithin and menthol is 30% of the total weight of the materials in step (1). The material was placed in a sand mill and dispersed at 2500rpm for 1.5 hours.

[0047] (3) Mix the materials of steps (1) and (2), and add the binder to stir; wherein the preparation method of the binder is: dissolve the ethyl cellulose resin with menthol, and make the ethyl cellulose The concentration (w / v) was 20%. The add-on of binding agent is 40% of step (1) material gross weight.

[0048] (4) Grinding and dispersing with a three-roll mill for 4.5 hours.

[0049] (5) After dilution, carry out precision filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com