Deoiling agent for oilfield binary composite displacement output sewage and preparation method thereof

A binary compound and degreasing agent technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the complex preparation and use process, high cost, poor degreasing effect, etc. problems, to achieve the effect of simple preparation process and use process, good economic and social benefits, and weak flocculation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Degreaser A 1 And its joint station D in Shengli Oilfield 1 Applications

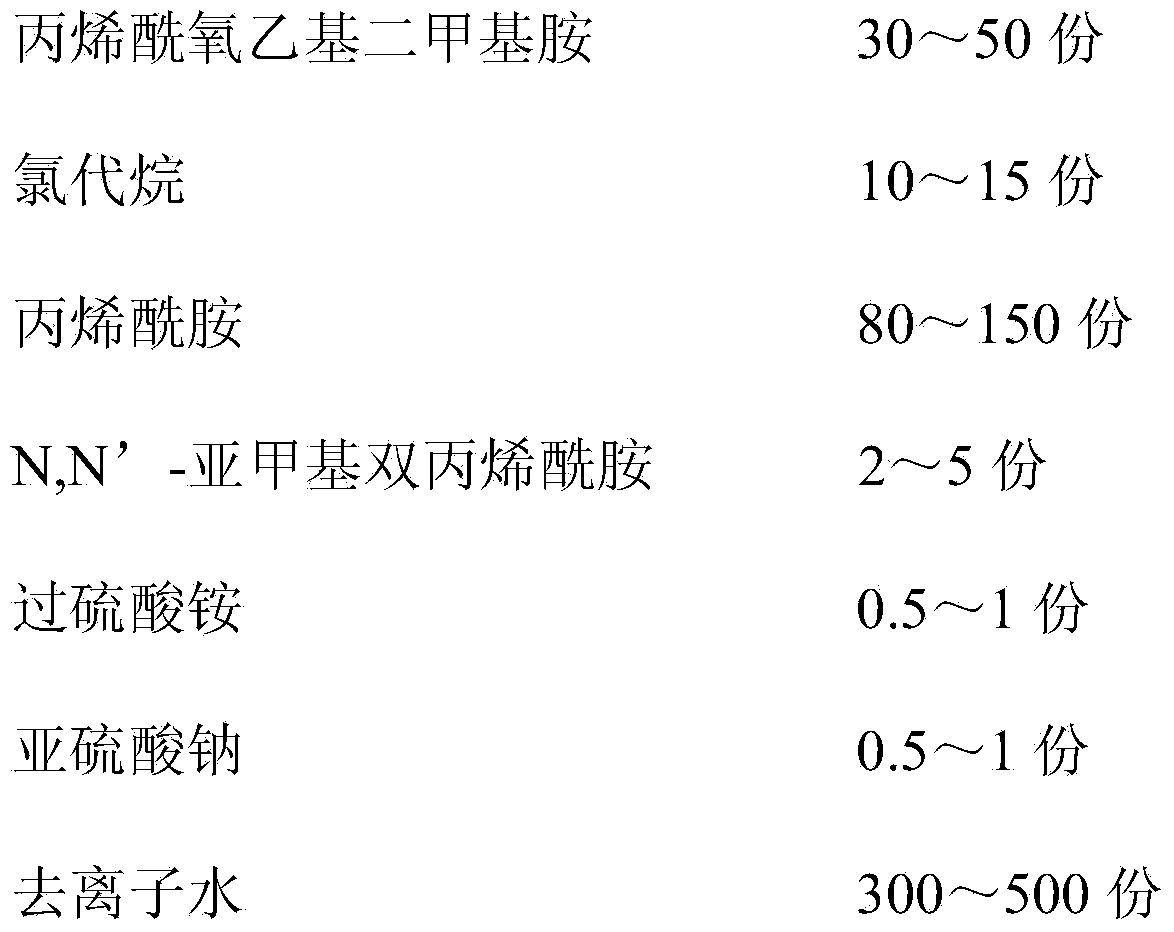

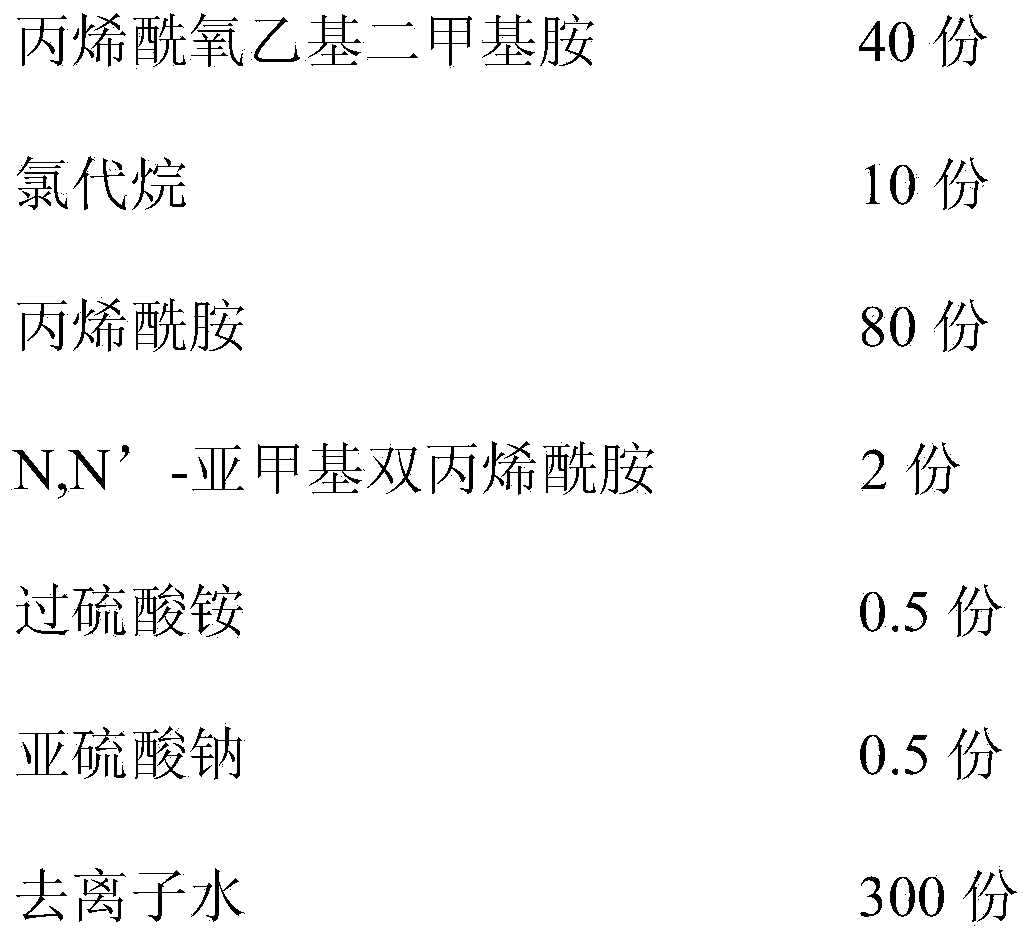

[0024] (1) Degreaser A 1 The composition and components are as follows:

[0025]

[0026] (2) Degreaser A 1 The specific preparation method is as follows:

[0027] ① React 40 parts of acryloyloxyethyl dimethylamine with 10 parts of methyl chloride to form a cationic monomer.

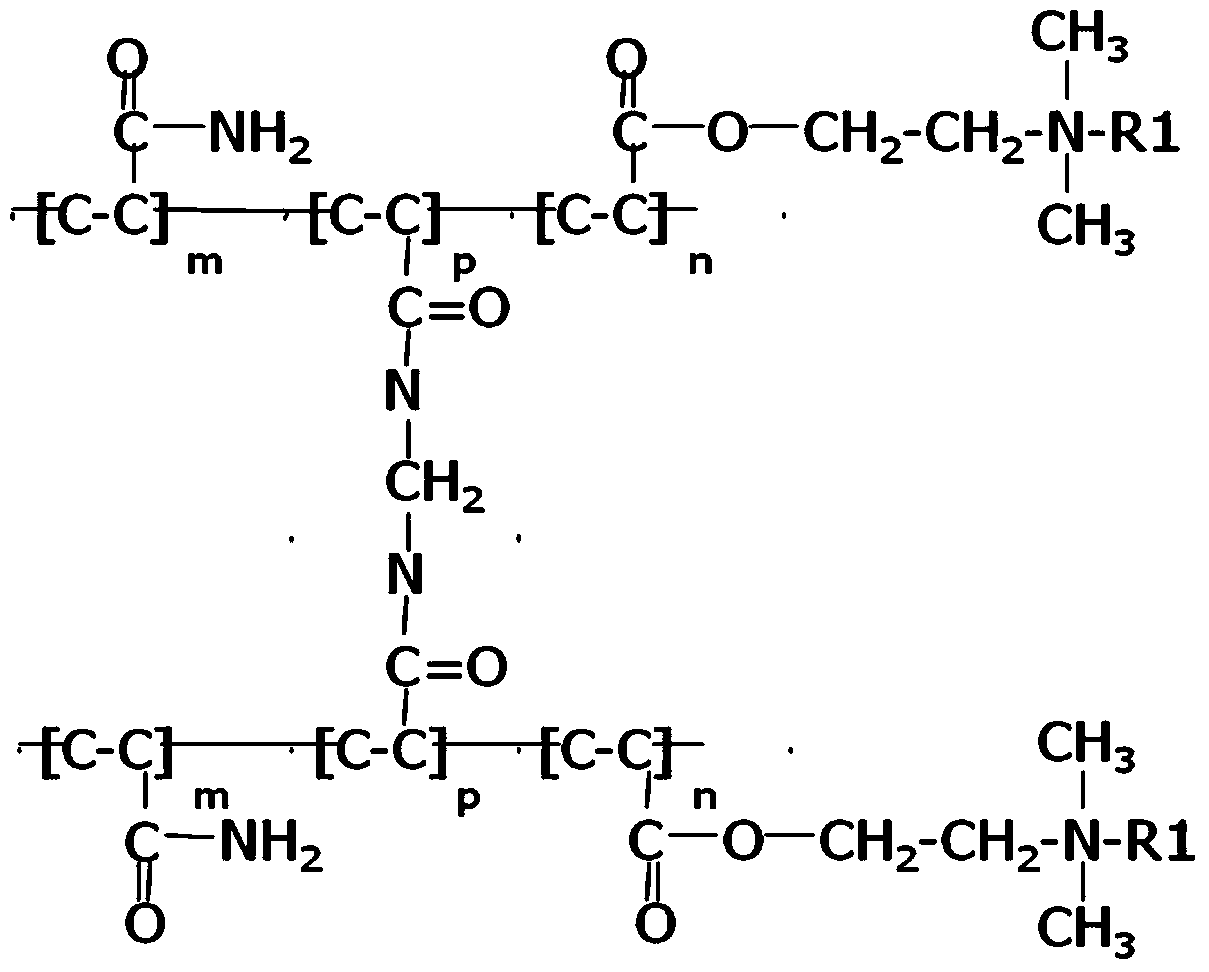

[0028] ②Mix 80 parts of acrylamide and 2 parts of N,N'-methylenebisacrylamide, add 300 parts of deionized water in 3 times, stir while adding, add the above cationic monomer after the dissolution is complete, and then add 0.5 Ammonium persulfate and 0.5 parts of sodium sulfite solution were stirred at 30°C for 5 hours to obtain degreaser A 1 , A 1 The structural formula is as follows:

[0029]

[0030] where m=10, n=3, p=0.1

[0031] Union Station D 1 The incoming water is the produced water of binary compound flooding, and the test treatment scale is 20m 3 / d, the oil content of incoming wat...

Embodiment 2

[0032] Embodiment 2: Degreaser A 2 And its joint station D in Shengli Oilfield 2 Applications

[0033] (1) Degreaser A 2 The composition and components are as follows:

[0034]

[0035] (2) Degreaser A 2 The specific preparation method is as follows:

[0036] ①React 50 parts of acryloyloxyethyl dimethylamine with 15 parts of chlorooctane to form a cationic monomer.

[0037] ②Mix 150 parts of acrylamide and 5 parts of N,N'-methylenebisacrylamide, add 500 parts of deionized water in 3 times, stir while adding, add the above cationic monomer after the dissolution is complete, and then add 1 One part of ammonium persulfate and one part of sodium sulfite solution, stirred at 45°C for 4 hours to obtain degreaser A 2 , A 2 The structural formula is as follows:

[0038]

[0039] where m=20, n=4, p=0.3

[0040] Union Station D 2 The influent water is binary compound flooding produced water, and the test treatment scale is 50m 3 / d, the oil content of incoming water is...

Embodiment 3

[0041] Embodiment 3: Degreaser A 3 And its joint station D in Shengli Oilfield 3 Applications

[0042] (1) Degreaser A 3 The composition and components are as follows:

[0043]

[0044] (2) Degreaser A 3 The specific preparation method is as follows:

[0045] ① React 30 parts of acryloyloxyethyl dimethylamine with 12 parts of chloropentane to form cationic monomers.

[0046] ②Mix 100 parts of acrylamide and 3 parts of N,N'-methylenebisacrylamide, add 500 parts of deionized water in 3 times, stir while adding, add the above cationic monomer after the dissolution is complete, and then add 0.8 One part of ammonium persulfate and 0.8 part of sodium sulfite solution, stirred at 60°C for 3 hours to obtain degreaser A 3 , A 3 The structural formula is as follows:

[0047]

[0048] where m=14, n=2, p=0.2

[0049] Union Station D 3 The incoming water is the produced water of binary compound flooding, and the test treatment scale is 20m 3 / d, the oil content of incomin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com