WO3-ZnO composite target and preparation method thereof

A technology of target material and composite ceramics, applied in the field of inorganic non-metallic elements and their compounds, can solve the problems of affecting optoelectronic properties, difficult to sinter and dense, low self-diffusion coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

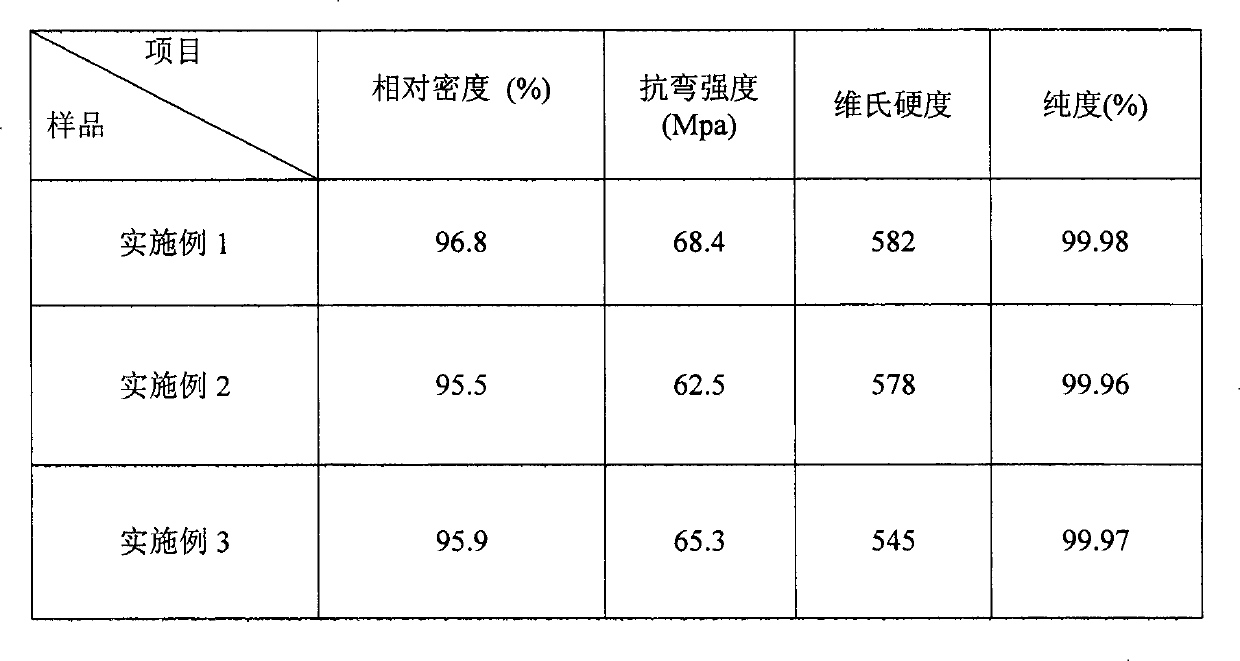

[0010] Take by weighing 200g purity 99.99% zinc oxide powder (average particle size 100 nanometers), 70g purity is 99.99% tungsten trioxide powder (average particle size 80 nanometers), and 13g purity is the polyethylene glycol 10000 of 99.9% as molding agent, Add the above-mentioned raw materials into deionized water and wet mill them in a ball mill for 24 hours, then dry the ball-milled raw materials at 60°C for 12 hours, pass through a 60-mesh sieve, and press them under a pressure of 100 MPa. After the sample was kept at 400°C for 4 hours to release the molding agent, it was continuously heated to 1250°C and sintered in the air under normal pressure for 120 minutes, and then cooled with the furnace to obtain highly dense WO. 3 -ZnO composite target, its related performance parameters are shown in figure 1 .

Embodiment 2

[0012] Take by weighing 100g purity be 99.99% zinc oxide powder (average particle size 10 microns), 23g purity be 99.99% tungsten trioxide powder (average particle size 17 microns), and 6g purity be the polyethylene glycol 10000 of 99.9% as molding agent , add the above raw materials into deionized water and wet mill them in a ball mill for 36 hours, then dry the ball milled raw materials at 80°C for 8 hours, pass through a 40-mesh sieve, press them under a pressure of 150Mpa, and press them After the molded sample is kept at 450°C for 3 hours to remove the molding agent, it is continuously heated to 1400°C and sintered in the air at normal pressure for 200 minutes, and then cooled with the furnace to obtain a highly dense WO 3 -ZnO composite target, its related performance parameters are shown in figure 1 .

Embodiment 3

[0014] Take by weighing 300g purity be the zinc oxide powder (average particle size 80 nanometers) of 99.99%, 180g purity be the tungsten trioxide powder (average particle size 5 microns) of 99.99%, and 20g purity be the polyethylene glycol 10000 of 99.9% as molding agent , add the above raw materials to deionized water and wet mill them in a ball mill for 18 hours, then dry the ball milled raw materials at 100°C for 5 hours, pass through a 50-mesh sieve, and press them under a pressure of 120Mpa. After the molded sample is kept at 500°C for 2.5 hours to remove the molding agent, it is continuously heated to 1350°C and sintered in the air under normal pressure for 180 minutes, and then cooled with the furnace to obtain a highly dense WO 3 -ZnO composite target, its related performance parameters are shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com