Method for separating mixture of catalytic cracking rich gas and methanol-to-olefin reaction product

A technology for producing olefins and reaction products from methanol, which is applied in the fields of producing hydrocarbons from oxygen-containing organic compounds, organic chemistry, refining and cracking processes only in multi-stage series, etc. To wait for the problem, to achieve the effect of reducing investment, reducing the degree of transformation, and small changes in kettle temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

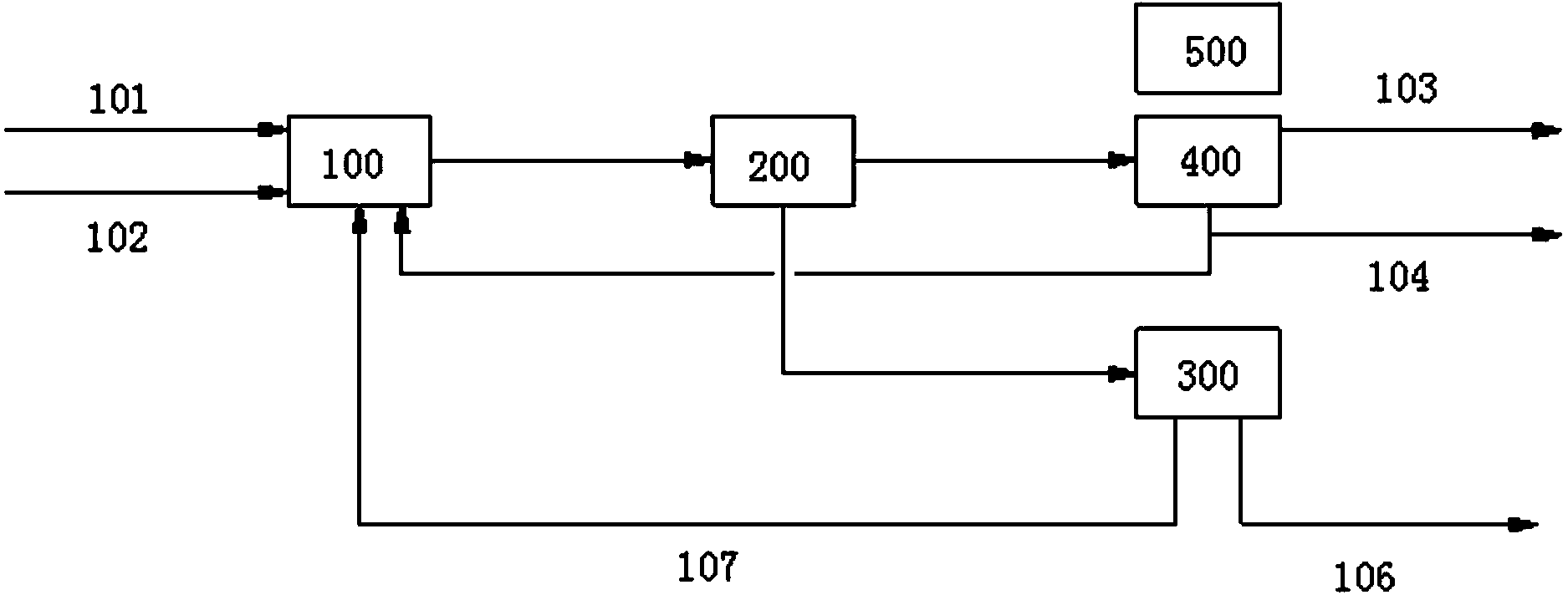

[0041] Figure 4 In the method for mixing and separating catalytic cracking rich gas and methanol-to-olefins reaction products of the present invention: 100 methanol-to-olefins reaction units, 200 compression units, 300 separation heat zones, 600 catalytic cracking units, 700 absorption stabilization units, and 800 gas fractionation units.

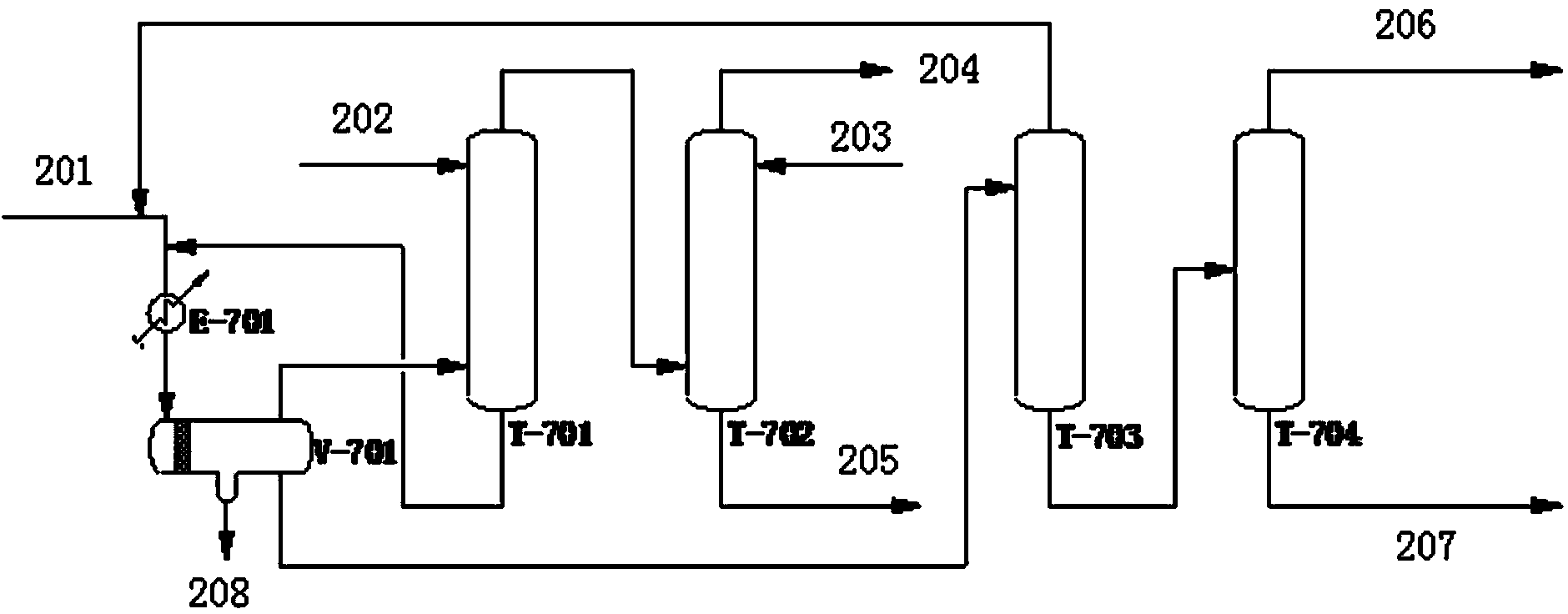

[0042] Figure 5 with Image 6 In the flow chart of the compression unit of the present invention: T-201 pre-depropanizer;

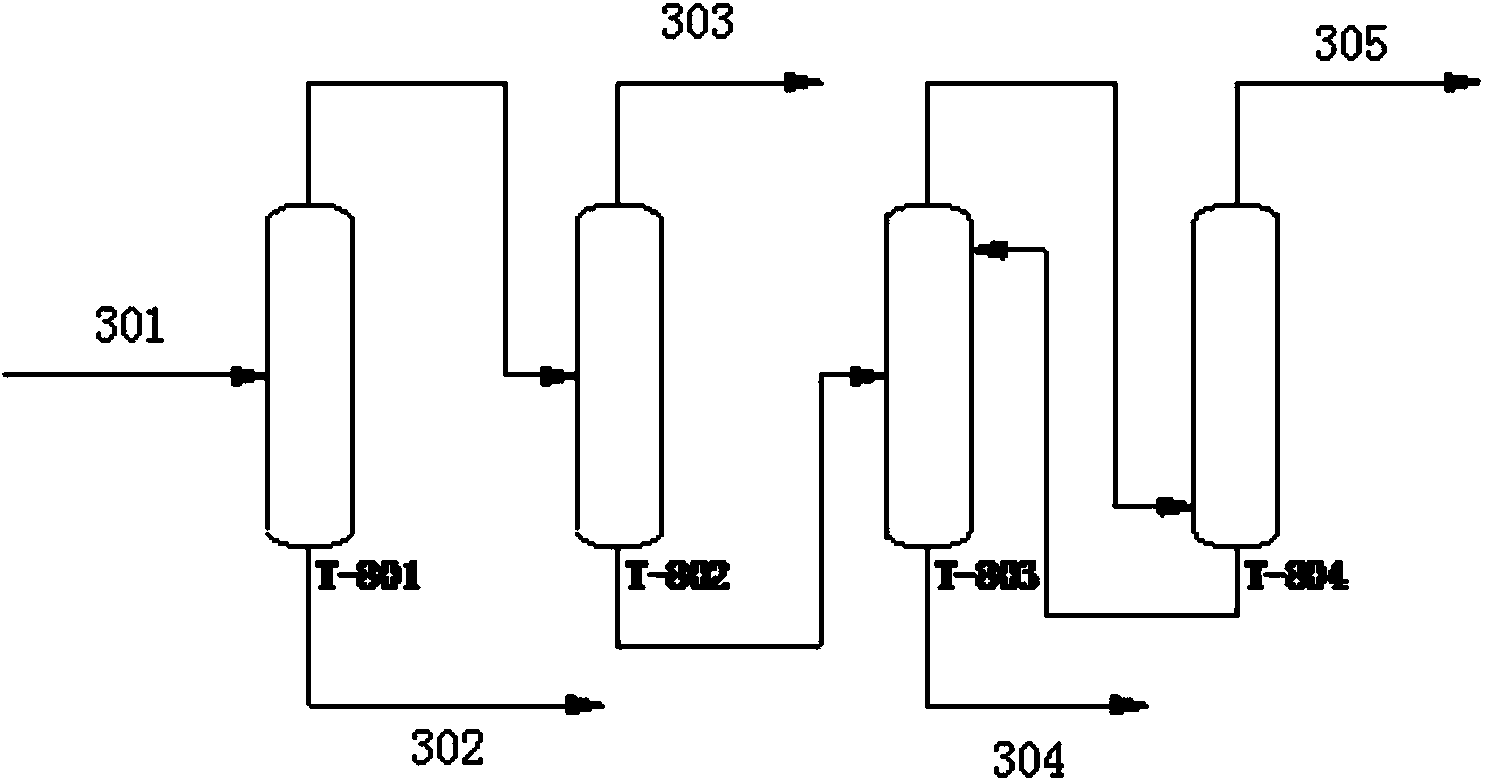

[0043] Figure 7 In the flow chart of the separation heat zone of the present invention: T-301 dehexanizer, T-302 debutanizer;

[0044] Method for mixing and separating catalytic cracking rich gas and methanol to olefins reaction products ( Figure 4 ) is: methanol to olefins reaction unit 100 uses methanol 401 as raw material, steam 402, C4-C6 circulating hydrocarbon 403 and C4 circulating hydrocarbon 417 as diluent gas to carry out catalytic reaction in an adiabatic fixed bed, and the reaction product is heat r...

Embodiment 2

[0058] Near certain 1,000,000 tons / year catalytic cracking unit, newly build a set of 250,000 tons / year methanol feedstock methanol-to-olefins unit, the flow process used adopts catalytic cracking rich gas of the present invention and methanol-to-olefins reaction product mixed separation method ( Figure 4 ). The original absorption stabilization unit 700 and gas fractionation unit 800 of the catalytic cracking unit are used to separate the reaction products of the methanol-to-olefins unit, and the methanol-to-olefins unit only needs to build a methanol-to-olefins reaction unit 100 and a compression unit 200 ( Figure 5 ) and separation hot zone 300 ( Figure 7 ).

[0059] The pressure of the rich gas produced by the catalytic cracking unit is 1.00MPaG, and the mass ratio of C3 and C4 in the rich gas is 0.50. The reaction unit of the new methanol-to-olefins plant adopts the existing disclosed technology, and the compression unit 200 adopts the following Figure 5 The flow s...

Embodiment 3

[0071] Near a certain 1,500,000 tons / year catalytic cracking unit, newly build a set of 300,000 tons / year methanol feedstock methanol-to-olefins unit, the separation process adopts the mixed separation method of catalytic cracking rich gas and methanol-to-olefins reaction product of the present invention ( Figure 4 ). Using the original absorption stabilization unit 700 and gas fractionation unit 800 of the catalytic cracking unit to replace the separation cold zone 400 and the propylene refrigeration unit 500 to separate the reaction products of the methanol-to-olefins unit, the methanol-to-olefins unit only needs to build a new methanol-to-olefins reaction unit 100, Compression unit 200 ( Image 6 ) and separation hot zone 300 ( Figure 7 ), requiring only minor modifications to the original absorption stabilization unit 700 and gas fractionation unit 800.

[0072] The pressure of the rich gas produced by the catalytic cracking unit is 0.90 MPaG, and the mass ratio of C3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com