Lincomycin fermentation liquor treatment process

A technology of lincomycin and treatment process, which is applied to the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve problems such as environmental pollution and waste of resources, and achieve avoidance of large quantities of discharge, reduction of processing burden, and clarity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

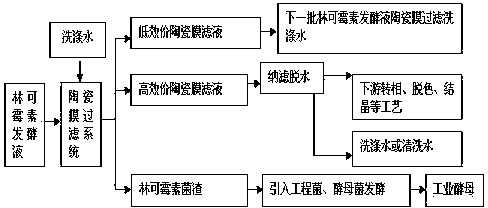

Image

Examples

Embodiment 1

[0018] Complete the lincomycin fermented liquid treatment with reference to the steps shown in the accompanying drawings, and the concrete steps are as follows:

[0019] (1) Acidify the lincomycin fermentation broth with a fermentation unit of 8000-9000u / ml, and pump it into a fully closed ceramic membrane filtration system. The precision of the ceramic membrane is 500nm, the membrane inlet pressure is 0.35-0.45MPa, and the membrane outlet pressure is 0.20 -0.30MPa, filtration temperature 50-60℃;

[0020] (2) During the ceramic membrane filtration process, when the concentration factor of the lincomycin fermentation broth is 3.5, continuously add washing water with a mass of 1.5-2.0 times the fermentation broth at a certain speed for washing until the lincomycin fermentation broth filtrate When the titer is as low as 200-300u / ml, stop the ceramic membrane filtration, and collect the ceramic membrane filtrate and bacterial residue;

[0021] (3) Concentrate and dehydrate the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com