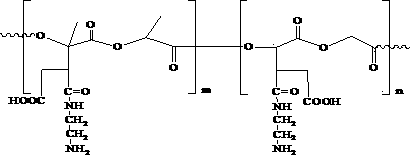

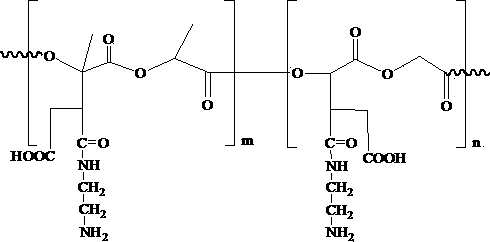

Preparation method of ethylenediamine modified maleic anhydride polylactide-glycolide polymer

A technology of maleic anhydride and polylactide, applied in the field of preparation of modified polylactide, which can solve the problems of skin and nervous system irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 10g of MPLGA in 27ml of chloroform to prepare 20wt% MPLGA in chloroform, and mix equal volumes of ethylenediamine and chloroform to prepare 38wt% ethylenediamine in chloroform. Add the chloroform of MPLGA into a three-necked flask equipped with a stirrer and a thermometer, add 2ml of ethylenediamine in chloroform under stirring, and control the system temperature below 10°C with an ice bath. After the dropwise addition was completed and kept warm for 5 min, the temperature was raised to room temperature and reacted for 60 min. The product was dropped into an excess ethanol solution to precipitate and was washed with deionized water to become neutral. The product was vacuum-dried at 40 °C to constant weight to obtain a yellow EMPLGA solid. The resulting product M w =27775, M w / M n =1.70.

Embodiment 2

[0024] 10g of MPLGA was dissolved in 16ml of chloroform to prepare a 30wt% MPLGA solution in chloroform, and equal volumes of ethylenediamine and chloroform were mixed to prepare a 38wt% ethylenediamine solution in chloroform. Add the chloroform of MPLGA into a three-necked flask equipped with a stirrer and a thermometer, add 1ml of ethylenediamine in chloroform solution under stirring conditions, and control the system temperature below 10°C with an ice bath. After the dropwise addition was completed and kept warm for 10 min, the temperature was raised to room temperature and reacted for 30 min. The product was dropped into an excess ethanol solution to precipitate and was washed with deionized water to become neutral. The product was vacuum-dried at 40 °C to constant weight to obtain a yellow EMPLGA solid. The resulting product M w =33262, M w / M n =1.65.

Embodiment 3

[0026] Dissolve 10g of MPLGA in 20ml of chloroform to prepare 25wt% MPLGA in chloroform, and mix equal volumes of ethylenediamine and chloroform to prepare 38wt% ethylenediamine in chloroform. Add the chloroform of MPLGA into a three-necked flask equipped with a stirrer and a thermometer, add 2ml of ethylenediamine in chloroform under stirring, and control the system temperature below 10°C with an ice bath. After the dropwise addition was completed and kept warm for 5 min, the temperature was raised to room temperature and reacted for 40 min. The product was dropped into an excess ethanol solution to precipitate and was washed with deionized water to become neutral. The product was vacuum-dried at 40 °C to constant weight to obtain a yellow EMPLGA solid. The resulting product M w =30347, M w / M n =1.71.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com