Method for preparing small-granularity cerium terbium lanthanum phosphate rare earth product with high luminous efficiency

A technology of lanthanum cerium terbium phosphate and high luminous efficiency, which is applied in the field of high luminous efficiency, rare earth phosphate-lanthanum cerium terbium phosphate, and can solve the problem of hard lumps formed by particles that are difficult to sieve, different particle size distribution and crystal morphology, precipitation performance and Poor filtering performance and other problems, to achieve the effect of low production conditions, low price, and good anti-attenuation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] A method for preparing a rare earth product of lanthanum cerium terbium phosphate with high luminous efficiency and small particle size, comprising the following steps:

[0015] (1) Prepare raw materials: select more than 99.99% LaCl3, CeCl3, TbCl3 as raw materials, and accurately weigh the corresponding raw materials according to the molar ratio required by the following chemical composition formula LaxCeyTb1-x-yPO4; the general chemical composition formula is LaxCeyTb1-x-yPO4 , the value range of x and y is: X is between 0.4 and 0.6, x + y > 0.8, the composition ratio of lanthanum, cerium and terbium is formulated to a concentration of 0.2-0.5 mol / l and a rare earth with an acidity of 0.1-0.2 mol / l Chloride salt or rare earth nitrate solution.

[0016] (2) Precipitation: use 0.5-1.0 mol / l phosphate-containing precipitant solution, add the above-mentioned feed liquid to the bottom liquid at 0.1-1.0 liter / min, and use the phosphate in the precipitant to react with rare ...

Embodiment 1

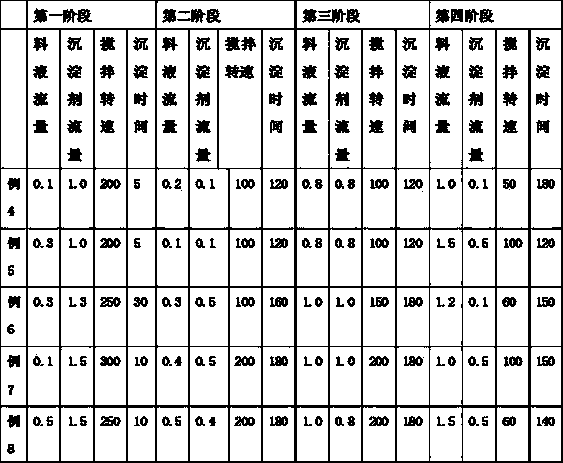

[0023] Embodiment 1: Mix evenly with the lanthanum chloride, cerium chloride and terbium chloride solution of the required ratio, adjust the concentration of the gained lanthanum chloride cerium terbium solution to 0.2~0.5mol / l, get a certain amount of diammonium hydrogen phosphate and dissolve to obtain A precipitant with a concentration of 0.5-1.0mol / l is added to the reactor with a bottom solution at a temperature of 25°C and an acidity of 0.1N, and at a stirring speed of 200 rpm, inject lanthanum cerium terbium chloride solution and dihydrogen phosphate Ammonium precipitant, the precipitation is carried out in four stages by the automatic feeding control system. At the beginning of the nucleation control stage, the flow rate of the feed liquid is controlled at 0.1 liters / minute, the flow rate of the precipitant is 1.0 liters / minute, and the precipitation time is 30 seconds after the nucleation In the transition control stage, the flow rate of the feed liquid is controlled a...

Embodiment 2

[0024]Embodiment 2: Mix evenly with the lanthanum chloride, cerium chloride and terbium chloride solution of the required ratio, adjust the concentration of the gained lanthanum chloride cerium terbium solution to 0.2~0.5mol / l, get a certain amount of diammonium hydrogen phosphate and dissolve to obtain A precipitant with a concentration of 0.5-1.0mol / l is added to the reactor with a bottom solution at a temperature of 25°C and an acidity of 0.1N, and at a stirring speed of 200 rpm, inject lanthanum cerium terbium chloride solution and dihydrogen phosphate Ammonium precipitant, the precipitation is carried out in four stages by the automatic feeding control system. At the beginning of the nucleation control stage, the flow rate of the feed liquid is controlled at 0.2 liters / minute, the flow rate of the precipitant is 1 liter / minute, and the precipitation time is 30 seconds after the nucleation In the transition control stage, the flow rate of the feed liquid is controlled at 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com