Method for extracting catalase from ox liver

A technology of catalase and bovine liver, which is applied in the biological field, can solve the problems of no industrial production, and achieve the effects of economical and environmentally friendly enzyme activity, increased yield, and shortened extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

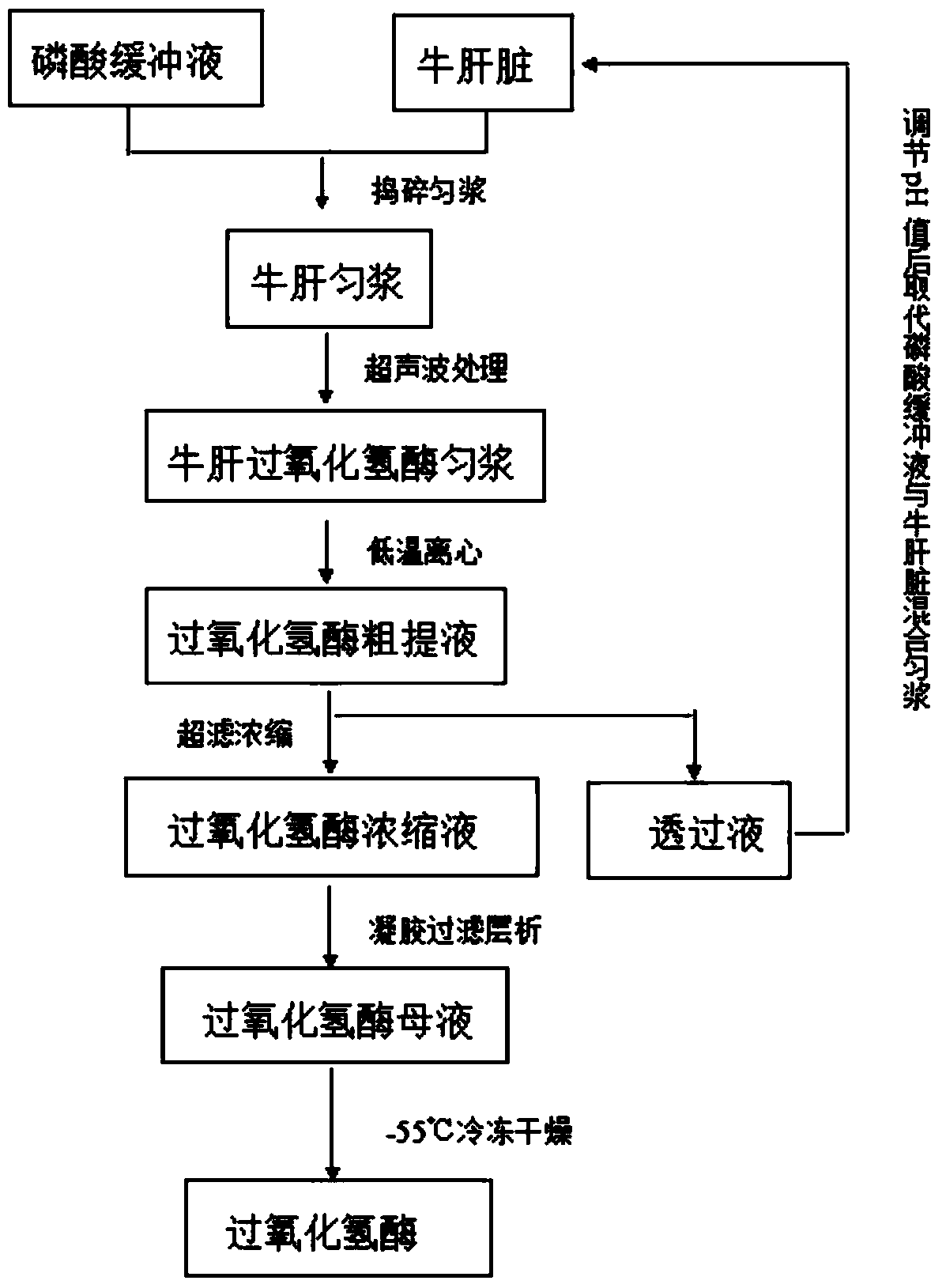

[0032] In the described method for extracting catalase from bovine liver, the preparation method of described catalase crude extract comprises the following steps:

[0033]Step 1, crush and homogenate, wash the fresh beef liver with water and chop it, mix the chopped beef liver with a phosphate buffer solution with a pH value of 7.0-7.8 according to the volume ratio of 1:6-10, and keep the temperature at 25 -30°C, use a tissue mashing homogenizer to mash for 20-30min, and the speed of the homogenizer is 2000-3000rpm to obtain bovine liver homogenate;

[0034] Step 2, ultrasonic extraction, the obtained bovine liver homogenate is ultrasonically oscillated for 10-30min, the ultrasonic intensity is 30-80W, the cells are broken, and the catalase in the cells is rapidly dissolved to obtain the bovine liver catalase homogenate;

[0035] Step 3, centrifugation, centrifuge the bovine liver catalase homogenate at 10-30°C for 15-25min in a low-temperature centrifuge, the speed of centri...

Embodiment 1

[0038] Wash 20kg of fresh beef liver with tap water, chop it, add 6 times the volume of phosphate buffer solution with a pH value of 7.2, mash it with a tissue masher homogenizer, and then extract it for 20 minutes with an ultrasonic intensity of 20W to obtain a homogenate of beef liver , take bovine liver homogenate, and then centrifuge at 6000 rpm for 20 minutes at 15°C with a low-temperature centrifuge, and the supernatant is the crude extract of catalase. Rinse the ultrafiltration equipment first, and after confirming that the pipes and containers are clean, fill the raw material tank with the feed liquid, and use Beijing Haideneng HU10-90 to conduct ultrafiltration concentration at a flow rate of 10L / h to obtain a concentrated solution of catalase. The excess liquid is recovered in the storage tank, and then adjusted to a pH value of 7.2 to replace the phosphate buffer used for crushing. The catalase concentrated solution that obtains adopts Sephacryl S-200 gel column to ...

Embodiment 2

[0040] Wash 20 kg of fresh beef liver with tap water, chop it, add 6 times the volume of phosphate buffer solution with a pH value of 7.4, mash it with a tissue masher homogenizer, and then extract it for 25 minutes with an ultrasonic intensity of 20W to obtain beef liver homogenate , take bovine liver homogenate, and then centrifuge at 6000 rpm for 20 minutes at 15°C with a low-temperature centrifuge, and the supernatant is the crude extract of catalase. Rinse the ultrafiltration equipment first, after confirming that the pipes and containers are clean, fill the raw material tank with feed liquid, and use Beijing Haideneng HU10-90 to conduct ultrafiltration concentration at a flow rate of 15L / h to obtain a concentrated solution of catalase, and through The liquid is recovered in the storage tank, and then adjusted to a pH value of 7.4 to replace the phosphate buffer used for crushing. The catalase concentrated solution that obtains adopts Sephacryl S-200 gel column to carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com