Roller drying system based on solar air heating

An air heating and drum drying technology, which is applied in the field of dryers and drum drying systems, can solve the problems of harmful substances entering printing and dyeing sludge, difficult to control the heating temperature, and poor drying effect, etc., and achieves easy implementation, industrial application, and drying effect Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

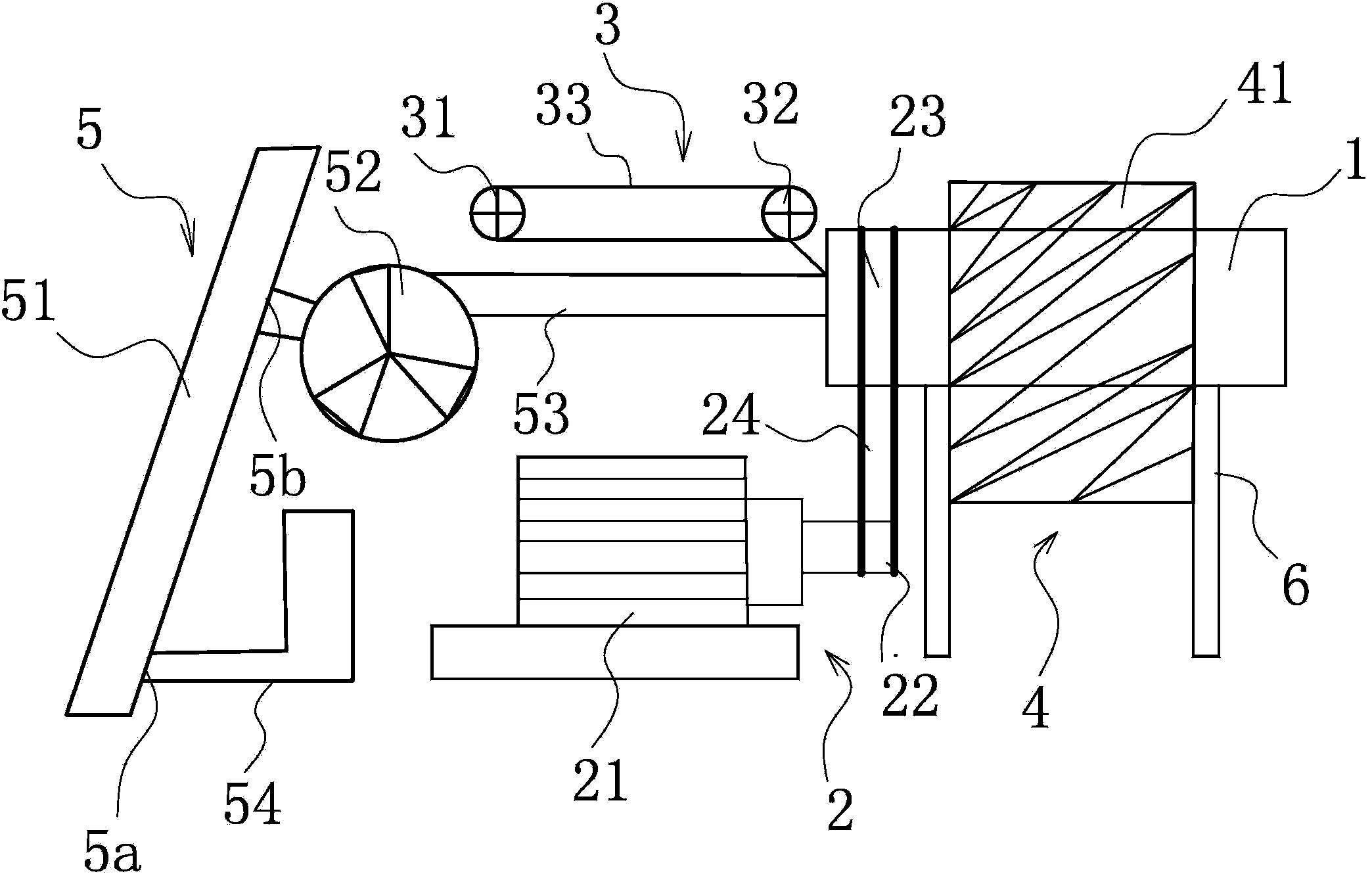

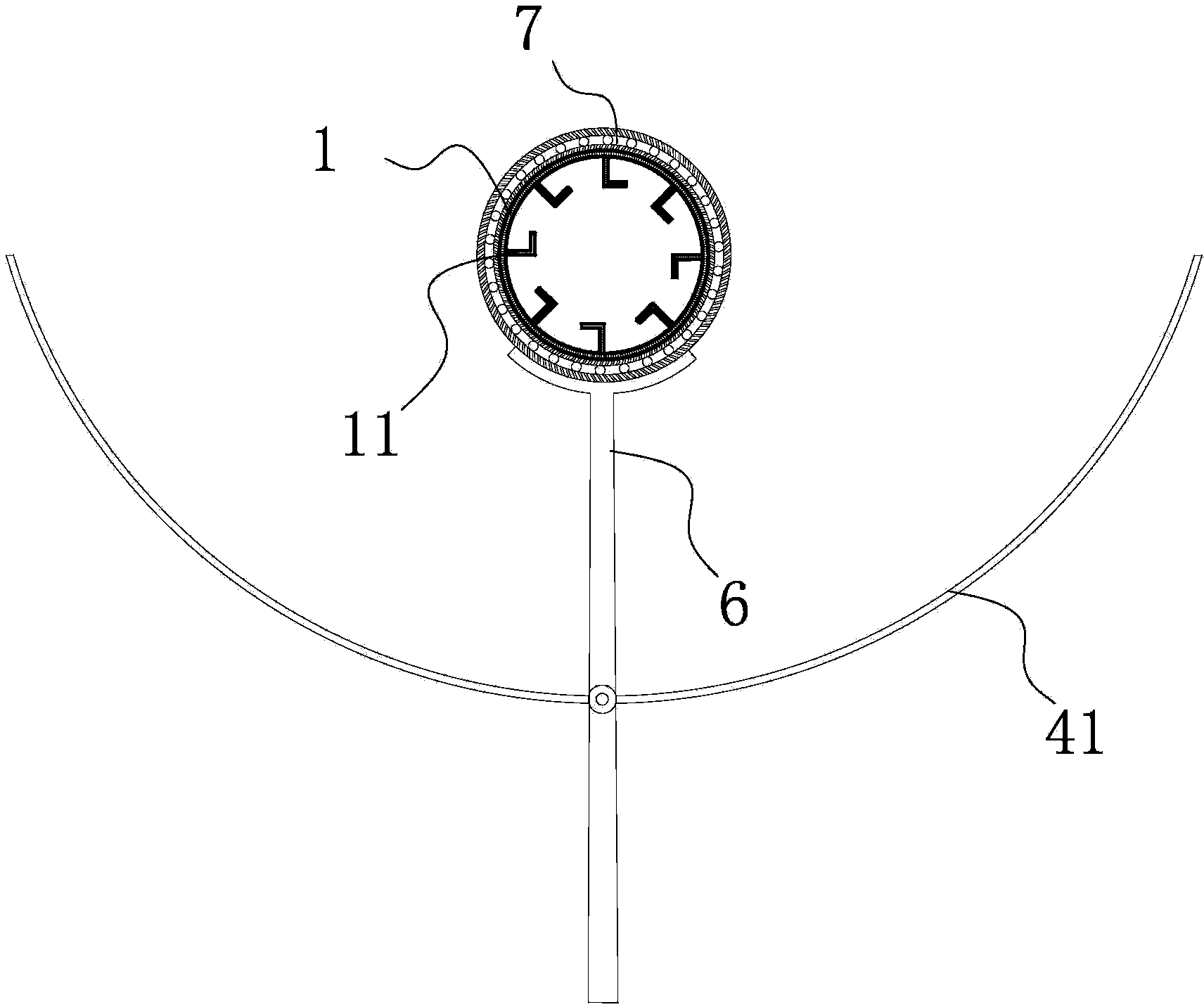

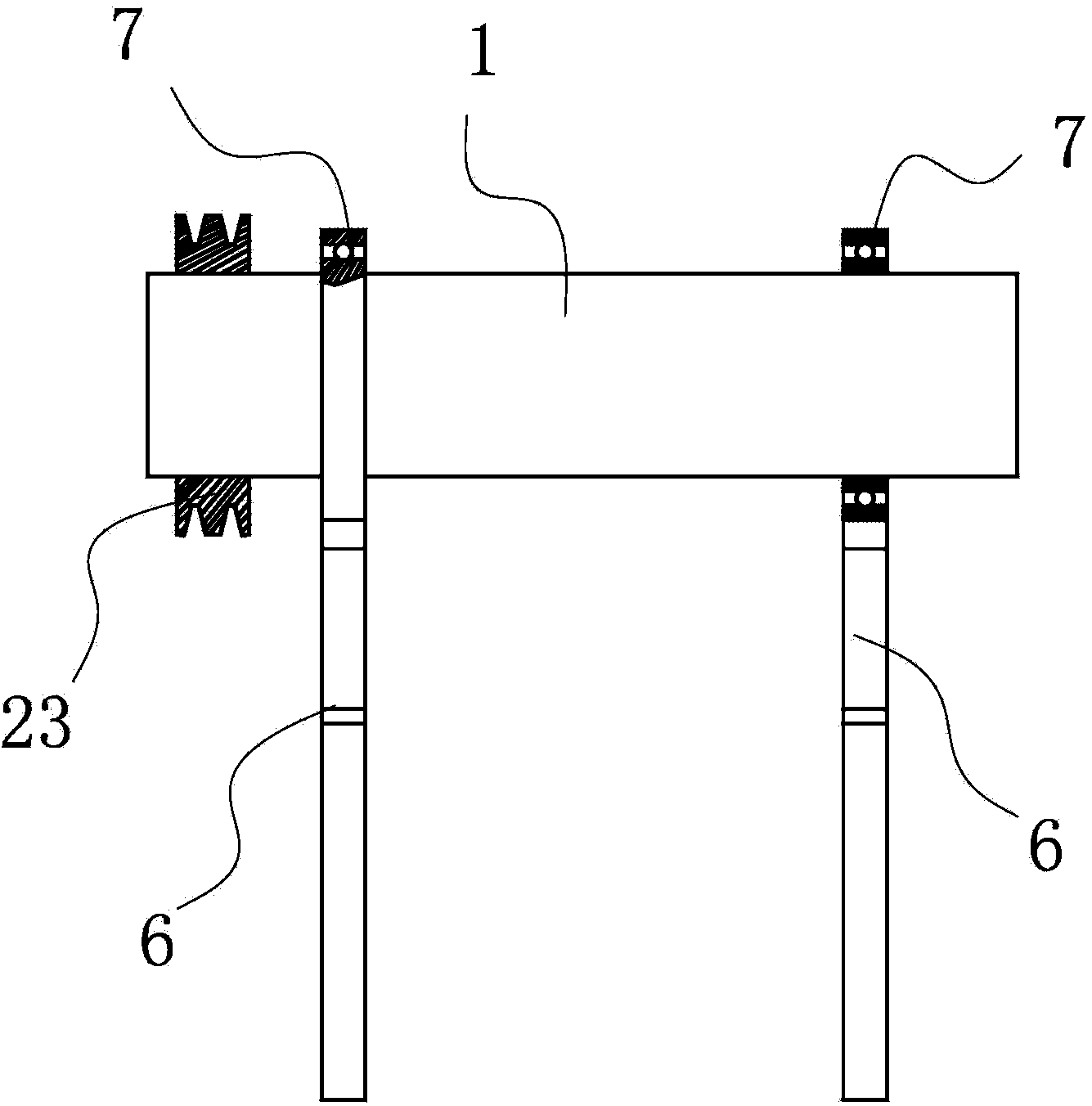

[0024] Such as Figure 1-3 As shown, the drum drying system based on solar air heating includes a drum 1, which is connected to a drive device 2 capable of driving the drum 1 to rotate, and a feeder that can transport materials into the drum 1 is provided at the feeding end of the drum 1 Material transfer device 3. Drum 1 periphery is provided with the solar heating device 4 that is used for drum 1 heating, and drum 1 one end is provided with the solar air heating device 5 that is used to deliver the thermal air flow that is heated by solar energy in drum 1. The sludge drying for the purpose of co-firing only needs to dry the sludge water content from about 85% to about 55%, so it can be achieved by solar drying. Furthermore, solar drying is at low temperature drying, and there will never be high-temperature pyrolysis of printing and dyeing sludge, which avoids the precipitation of volatile matter, not only saves the treatment of drying tail gas, but also provides higher calo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com