Inverted organic light emission diode and preparation method and application thereof

An electroluminescence device, an organic technology, applied in the field of electric light sources, can solve problems such as poor conductivity, difficulty in ensuring uniformity, and increased driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

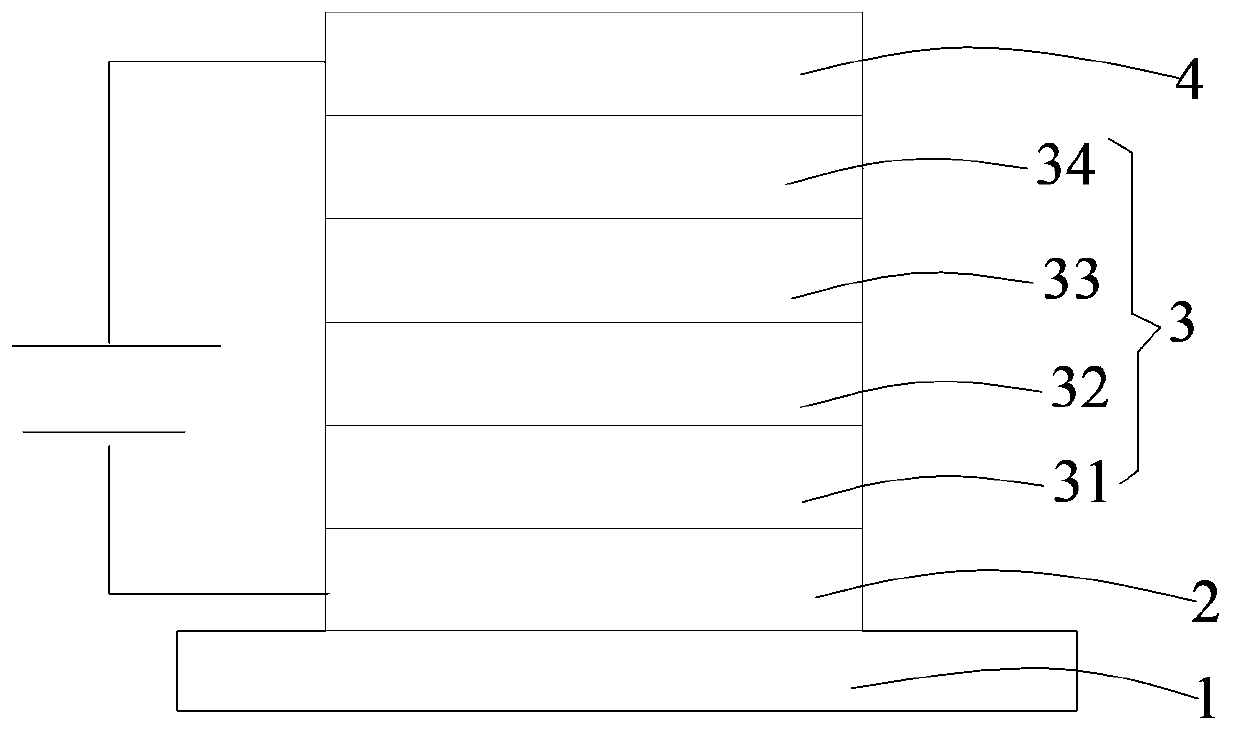

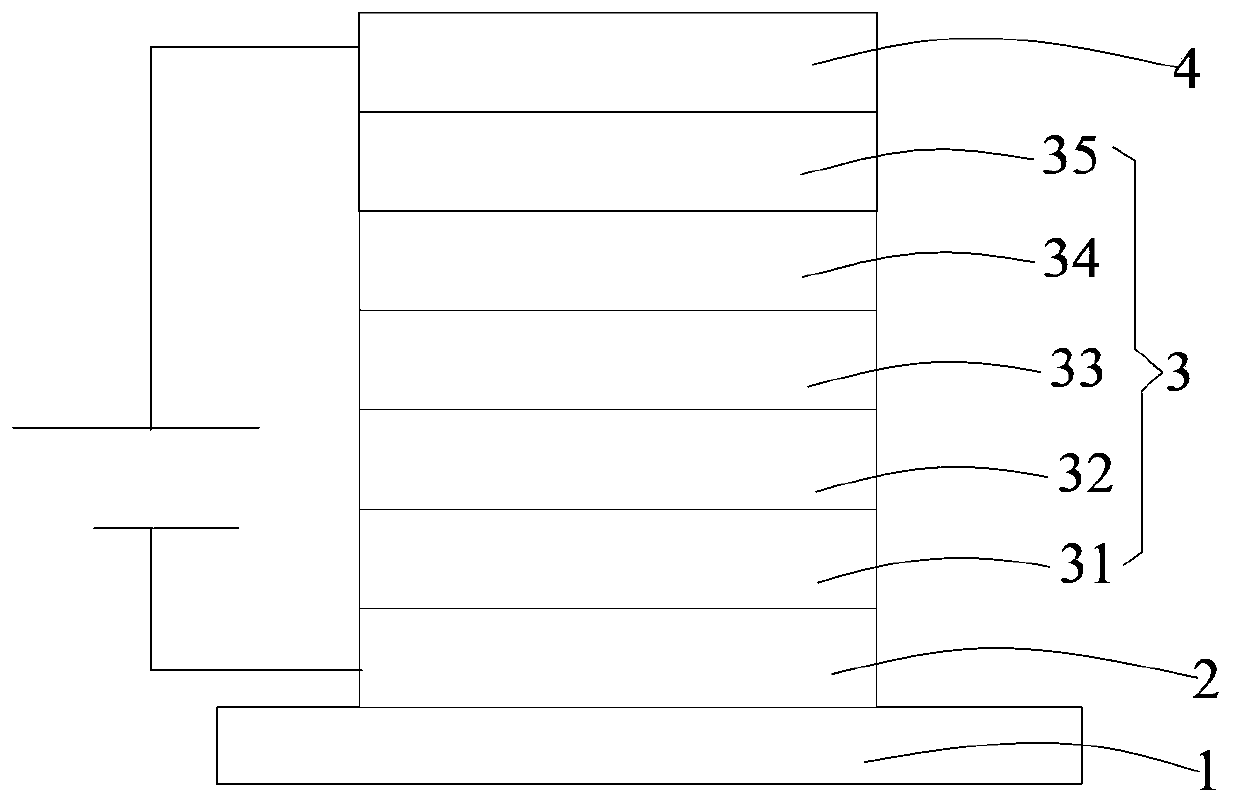

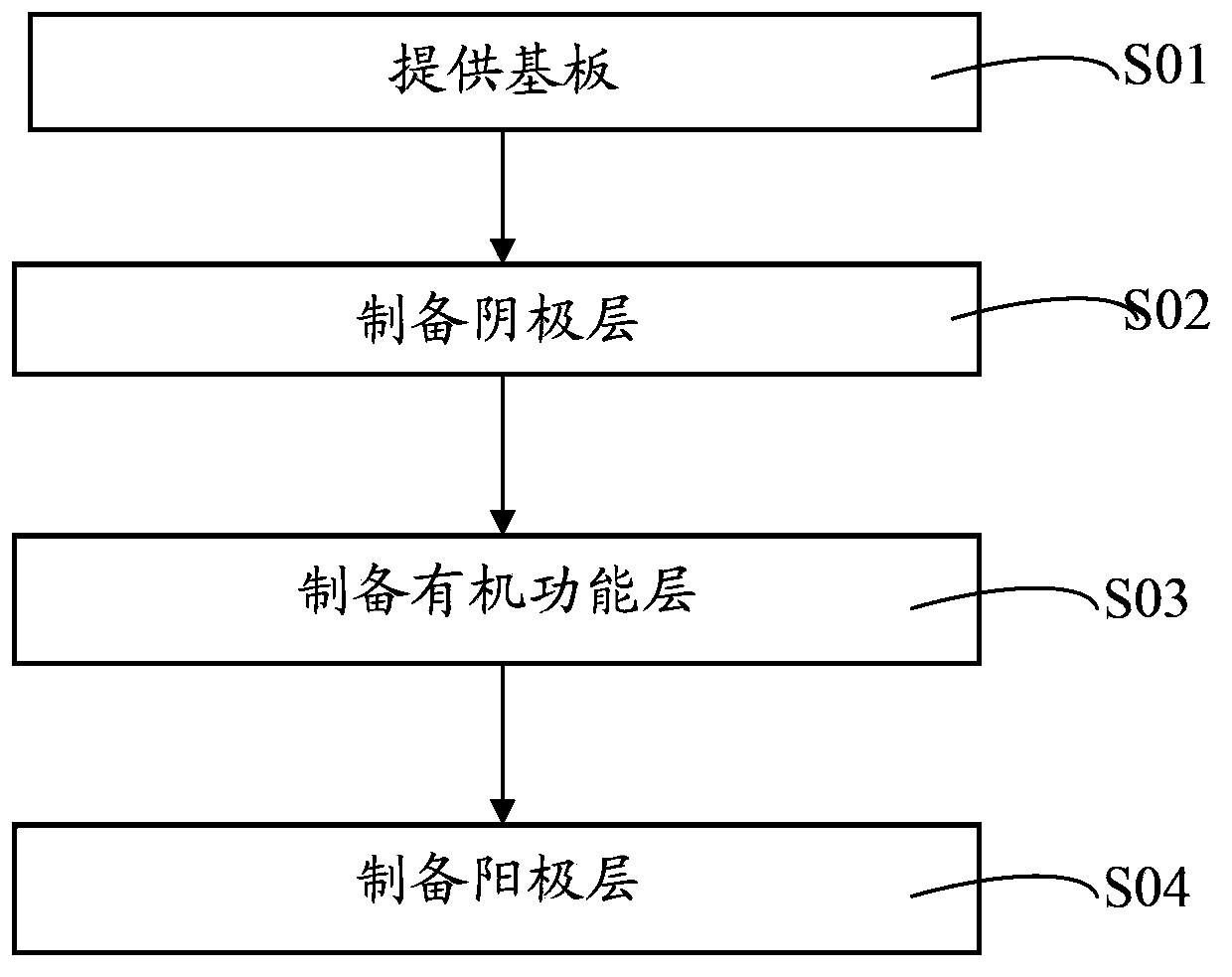

[0034] Correspondingly, the embodiment of the present invention also provides a method for preparing an inverted organic electroluminescence device as described above, the process flow of the method is as follows image 3 shown, see also Figure 1~2 . The preparation method of the inverted organic electroluminescence device comprises the following steps:

[0035] S01. Provide the substrate 1;

[0036] S02. Prepare the cathode layer 2: in a vacuum system, vapor-deposit the anode on the surface of the substrate 1 in step S01 to prepare the cathode layer 2;

[0037] S03. Preparation of the organic functional layer 3: in a vacuum system, using an electron beam evaporation process, lanthanum hexaboride is evaporated in step S02 to prepare the surface of the cathode layer 2 opposite to the surface of the light-transmitting substrate layer 1 to form electron injection. layer 31, and then sequentially prepare an electron transport layer 32, a light emitting layer 33 and a hole tran...

Embodiment 1

[0053] An inverted organic electroluminescence device, its structure is: glass substrate / Al (20nm) / electron injection layer LaB 6 (0.5nm) / electron transport layer (TPBi, 30nm) / luminescent layer (DPVBi, 10nm) / hole transport layer (TCTA, 30nm) / hole injection layer (CuPc, 10nm) / Ag (100nm). Wherein, the size of the light-emitting area of the inverted organic electroluminescence device is 3mm×3mm.

[0054] Its preparation method is as follows:

[0055] (1) At a vacuum of 10 -4 Prepared in the vacuum coating system of Pa, the glass substrate is cleaned with cleaning agent, then ultrasonically cleaned with distilled water and acetone in turn, and then in the coating system;

[0056] (2) Metal Al layers are evaporated sequentially on the substrate to form a cathode layer with a thickness of 20nm;

[0057] (3) LaB is sequentially prepared on the outer surface of the cathode layer 6 layer, TPBi layer, DPVBi layer, TCTA layer, CuPc layer, Ag layer, organic functional layer, and LaB...

Embodiment 2

[0061] An inverted organic electroluminescence device, its structure is: glass substrate / Al (20nm) / electron injection layer LaB 6 (15nm) / electron transport layer (TPBi, 30nm) / luminescent layer (DPVBi, 10nm) / hole transport layer (TCTA, 30nm) / hole injection layer (CuPc, 10nm) / Ag (100nm). Wherein, the size of the light-emitting area of the inverted organic electroluminescence device is 3mm×3mm.

[0062] For the preparation method of the inverted organic electroluminescent device, refer to the preparation method of the inverted organic electroluminescent device in Example 1. Among them, the preparation of LaB 6 The working pressure of vacuum deposition film formation is 1×10 -5 Pa, the evaporation rate of lanthanum hexaboride is 1nm / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com