Combined 1.9 mu m wavelength converter of hollow-core photonic crystal fiber and seal cavity

A technology of hollow-core photonic crystal and wavelength converter, which is applied in the field of optoelectronics, can solve the problem of low conversion efficiency of 1.9 μm laser light source, and achieve the effects of improving wavelength conversion efficiency, coupling efficiency and Raman conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

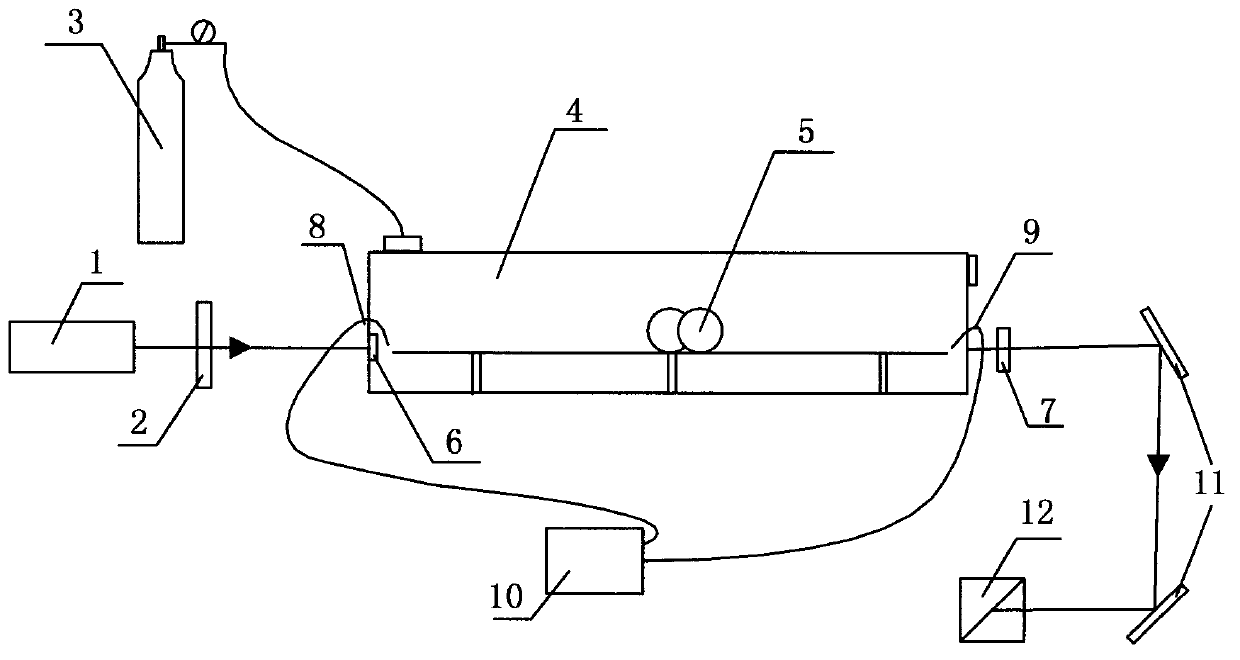

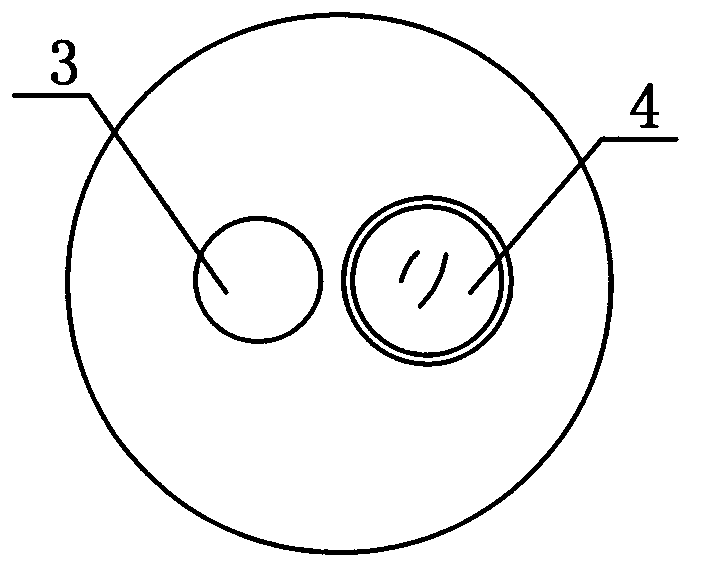

[0026] Such as figure 1 Shown is a combined 1.9 μm wavelength converter of a hollow-core photonic crystal fiber and a sealed cavity, which includes a laser (1) with a 1064nm pulse width of 5 ns and a power-tunable Nd:YAG nanosecond pulse laser with an energy lower than 330mJ; The polarization controller (2) uses a polarization device that can adjust the polarization state arbitrarily; the fiber collimator (6) adopts an aspheric fiber collimator with a focal length of 18mm, and its position is facing the hollow-core photonic crystal fiber (5); The steel cylinder (3) has a pressure reducing valve, and hydrogen gas of a certain pressure is filled into the sealed cavity (4); the sealed cavity (4) is made of stainless steel and can withstand 100 atm; the core diameter of the hollow-core photonic crystal fiber (5) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com