Betel nut brine and preparation technology thereof

A brine and betel nut technology, applied in the field of betel nut brine and its preparation, can solve the problems of inconvenient production, hindering mechanized and automatic brine making, and achieve the effects of easy drying, guaranteed color and quality, and improved continuous level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

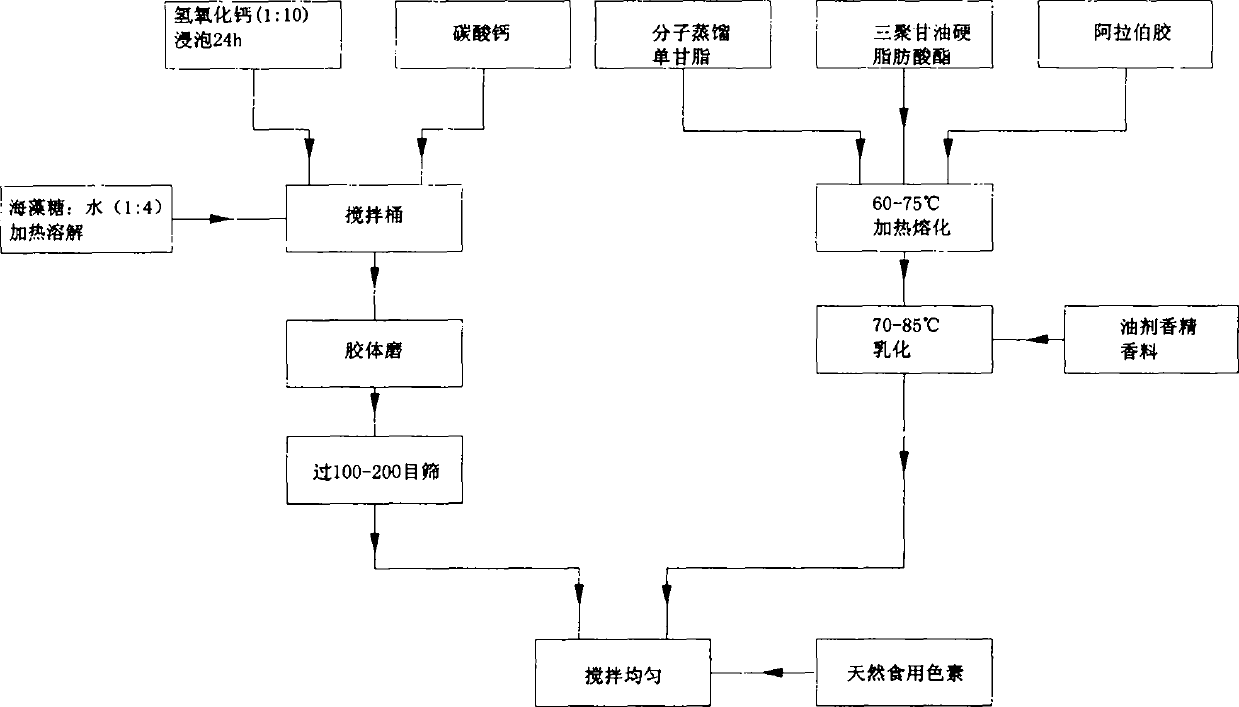

[0022] A kind of betel nut brine, which does not contain maltose in its formula, and is prepared from food-grade calcium hydroxide, food-grade calcium carbonate, trehalose, molecularly distilled monoglyceride, gum arabic, triglycerin stearate, oil essence and fragrance become. The brine preparation process flow chart is as follows figure 1 As shown, the preparation process is as follows:

[0023] (1) Dissolving and stirring: Add 5kg of food grade calcium hydroxide with water according to the material-to-water ratio of 1:10, heat, maintain the temperature at 80-100°C and soak for 24 hours, then take the supernatant and inject it into the mixing tank, and add 30kg of food grade calcium carbonate at the same time Put it into the mixing bucket, stir evenly and set aside;

[0024] (2) Dissolution of trehalose: After adding water to 10kg of trehalose according to the ratio of material to water of 1:4, heat to 60°C to dissolve;

[0025] (3) Homogenization: put the materials in ste...

Embodiment 2

[0029] A kind of betel nut brine, which does not contain maltose in its formula, and is prepared from food-grade calcium hydroxide, food-grade calcium carbonate, trehalose, molecularly distilled monoglyceride, gum arabic, triglycerin stearate, oil essence and fragrance become. The brine preparation process flow chart is as follows figure 1 As shown, the preparation process is as follows:

[0030] (1) Dissolving and stirring: add 10kg of food-grade calcium hydroxide with water according to the ratio of material to water 1:10, heat, maintain the temperature at 80-100°C and soak for 24 hours, then take the supernatant and pour it into the mixing tank, and add 40kg of food-grade calcium carbonate at the same time Put it into the mixing bucket, stir evenly and set aside;

[0031] (2) Dissolution of trehalose: add water to 15kg of trehalose according to the feed-to-water ratio of 1:4, and heat to 60°C to dissolve;

[0032] (3) Homogenization: Put the materials in step (1) and ste...

Embodiment 3

[0036] A kind of betel nut brine, which does not contain maltose in its formula, and is prepared from food-grade calcium hydroxide, food-grade calcium carbonate, trehalose, molecularly distilled monoglyceride, gum arabic, triglycerin stearate, oil essence and fragrance become. The brine preparation process flow chart is as follows figure 1 As shown, the preparation process is as follows:

[0037] (1) Dissolving and stirring: Add 5kg of food grade calcium hydroxide with water according to the material-to-water ratio of 1:10, heat, maintain the temperature at 80-100°C and soak for 24 hours, then take the supernatant and pour it into the mixing tank, and add 50kg of food grade calcium carbonate at the same time Put it into the mixing bucket, stir evenly and set aside;

[0038] (2) Dissolution of trehalose: After adding water to 20kg trehalose according to the ratio of material to water at 1:4, heat to 60°C to dissolve;

[0039] (3) Homogenization: Put the materials in step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com