In-situ tissue solidification engineering scaffold and preparation method thereof

A tissue engineering scaffold and in-situ curing technology, applied in the field of biomedicine, can solve the problems of low mechanical strength, unable to meet the needs of repairing load-bearing parts, etc., and achieve the effects of improved initial strength, simple preparation method and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

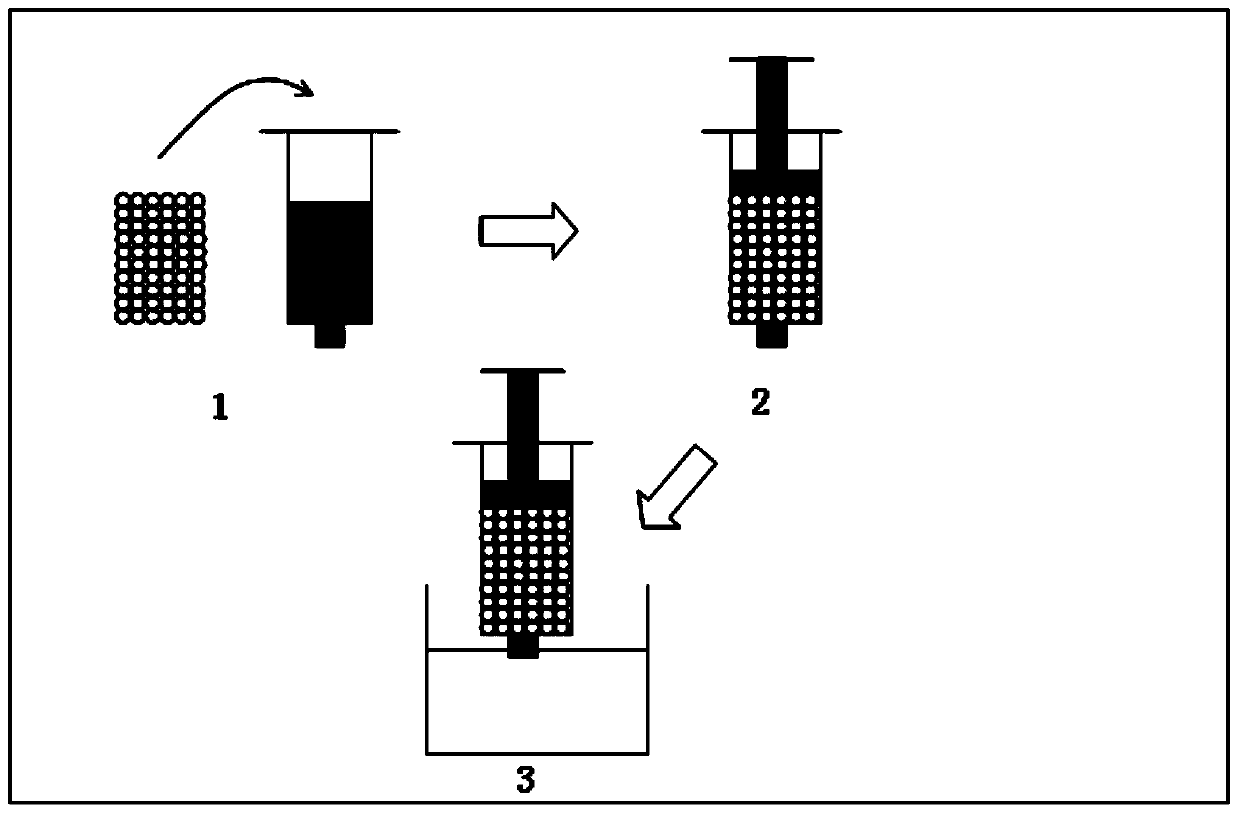

[0044] The present invention also provides a preparation method for in-situ solidified tissue engineering scaffold, comprising the following steps:

[0045] The polylactide-glycolide, biodegradable microspheres and polar organic solvents are mixed and cured in situ to obtain an in situ cured tissue engineering scaffold.

[0046] The present invention preferably mixes polylactide-glycolide (PLGA) with a polar organic solvent to obtain a PLGA solution, mixes biodegradable microspheres with the PLGA solution, and solidifies in situ to obtain in situ solidified tissue engineering stand. In order to make the obtained in-situ solidified tissue engineering scaffold applicable to bone tissue repair, the present invention preferably mixes PLGA, polar organic solvent and hydroxyapatite (HA) to obtain a PLGA solution, and mixes biodegradable microspheres with the The PLGA solution was mixed and solidified in situ to obtain an in situ solidified tissue engineering scaffold. In the prese...

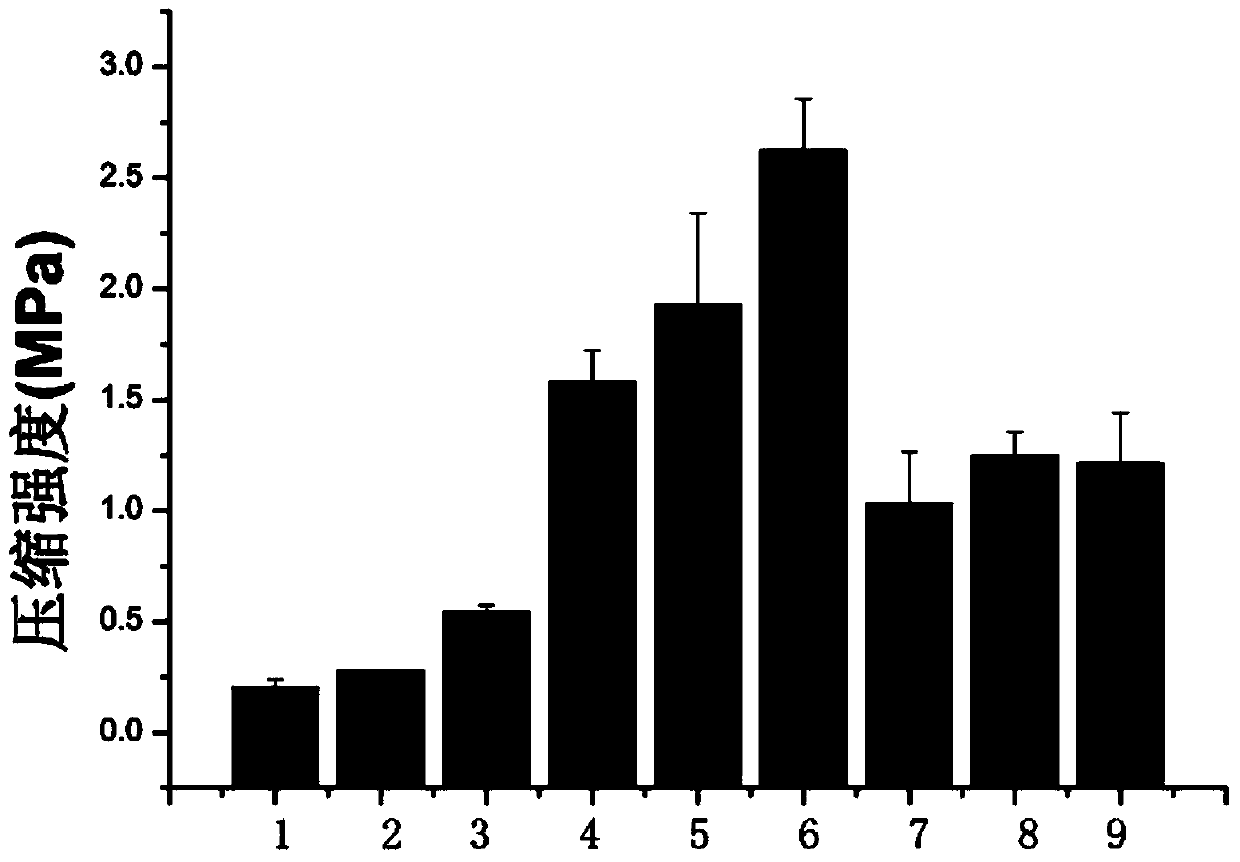

Embodiment 1

[0056] Gelatin was dissolved in deionized water at 37°C to prepare a gelatin solution with a mass concentration of 25%, and then after autoclaving at 120kPa, bone morphogenetic protein (BMP-2) was added to the gelatin solution to obtain BMP-2 A gelatin solution with a concentration of 500 ng / mL.

[0057] Add 20mL of liquid paraffin and 50μL of Span-80 into the beaker, stir evenly in a water bath at 37°C, add 10mL of gelatin solution into it, stir at 200rpm for 10min, then keep the speed constant, transfer to ice at 4°C Under bath conditions, stirring was continued for 1 h to obtain a mixture.

[0058] Filter through a filter with a pore size of 300 μm, and freeze-dry the filtered microspheres at -50° C. for 24 h.

[0059] The dried gelatin microspheres are quickly and repeatedly washed with absolute alcohol to obtain the gelatin microspheres.

[0060] At 80°C, dissolve 3g of PLGA in 10g of NMP, add 1g of HA, and stir evenly to obtain a PLGA solution.

[0061] Mix 5 g of PLG...

Embodiment 2

[0067] Gelatin was dissolved in deionized water at 37°C to prepare a gelatin solution with a mass concentration of 25%, and then after autoclaving at 123kPa, bone morphogenetic protein (BMP-2) was added to the gelatin solution to obtain BMP-2 A gelatin solution with a concentration of 500 ng / mL.

[0068] Add 20mL of liquid paraffin and 50μL of Span-80 into the beaker, stir evenly in a water bath at 37°C, add 10mL of gelatin solution into it, stir at 200rpm for 10min, then keep the speed constant, transfer to ice at 4°C Under bath conditions, stirring was continued for 1 h to obtain a mixture.

[0069] Filter through a filter with a pore size of 300 μm, and freeze-dry the filtered microspheres at -40° C. for 24 h.

[0070] The dried gelatin microspheres are quickly and repeatedly washed with absolute alcohol to obtain the gelatin microspheres.

[0071] At 80°C, dissolve 3g of PLGA in 10g of NMP, add 1g of HA, and stir evenly to obtain a PLGA solution.

[0072] Mix 6g of PLGA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com