A biological deodorization device with slow-release carbon as filler

A slow-release carbon filler, biological deodorization technology, applied in the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., to achieve good treatment effect, low price, high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

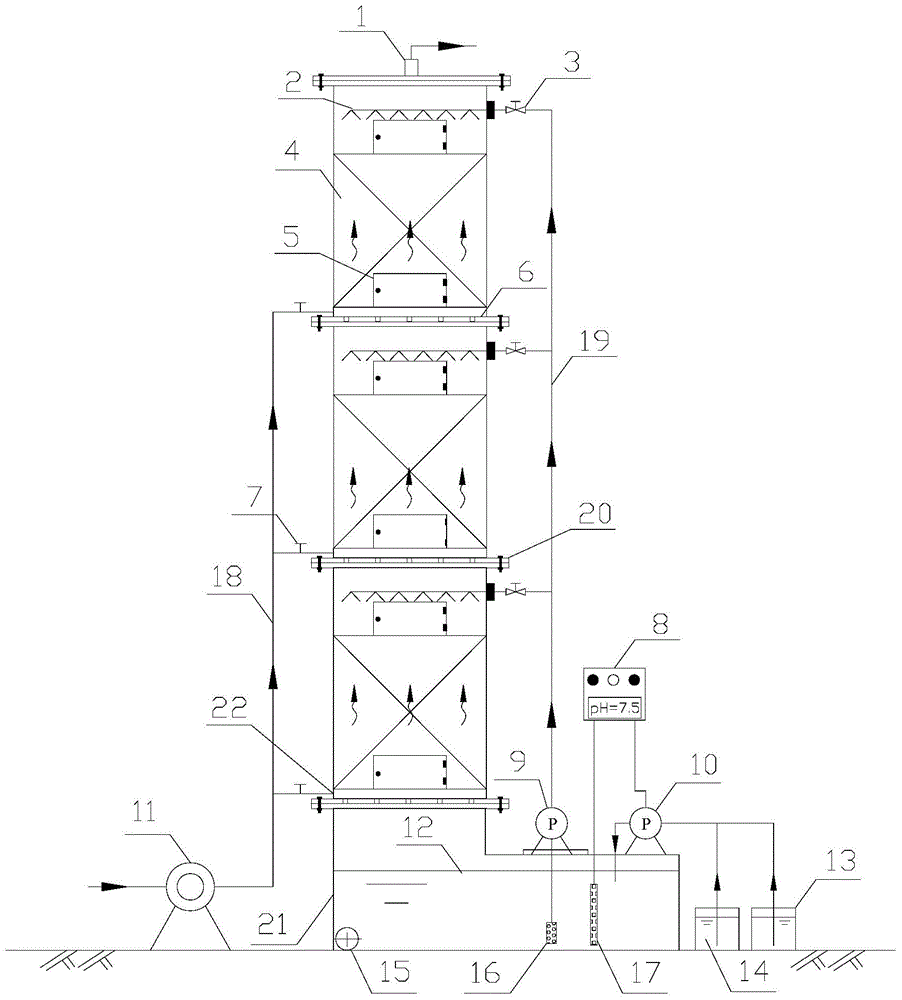

[0027] Using the above-mentioned deodorizing device, the ammonia-containing odor is transported by the air pump 11 to the air inlet 22 at the bottom of each independent deodorizing unit through the air inlet pipe 18 and the inlet valve 7, and the ammonia-containing odor flows through the perforated plate 6 and the filler The liquid phase in the layer is in contact with the microorganisms, and the purified odor is discharged from the top gas outlet 1. The spray liquid 12 in the spray liquid collection tank 21 is evenly sprayed on the surface of the slow-release carbon filler 4 through the filter 16, the spray pump 9, the spray pipe 19, the spray valve 3 and the spray device 2, and the spray density is 0.25~ 0.75m 3 Spray liquid / m 3 Filler h. The pH value of the spray liquid 12 in the spray liquid collection tank 21 is monitored by the pH probe 17, and maintained at about 7.5 ± 0.2 by the pH controller 8, the peristaltic pump 10, the sodium hydroxide solution 13 and the nitric...

Embodiment 2

[0031] Using the same device as in Example 1, the mass percentage of polylactic acid and starch in the filler of each independent deodorizing unit is greater than 90%, wherein the mass ratio of polylactic acid and starch is 4:6; the spray density is 0.5 ~ 1. 5m 3 Spray liquid / m 3 Filling h; The hydraulic retention time of the spray liquid in the biological trickling filter tower is 1 month. Other conditions are identical with embodiment 1.

Embodiment 3

[0033] Using the same device as in Example 1, the ammonia-containing odor produced only passes into the bottom of the first and second independent deodorizing units, and closes the air inlet of the third independent deodorizing unit; the spray density is 0.5 ~ 1.0 m 3 Spray liquid / m 3 Filler h. Other conditions are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com