Method for recycling sintered neodymium-iron-boron waste materials

A technology of waste recycling and neodymium iron boron, which is applied in the direction of recycling technology, can solve the problems of many production processes, low recovery rate and high cost, and achieve the effect of simple process, resource saving and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

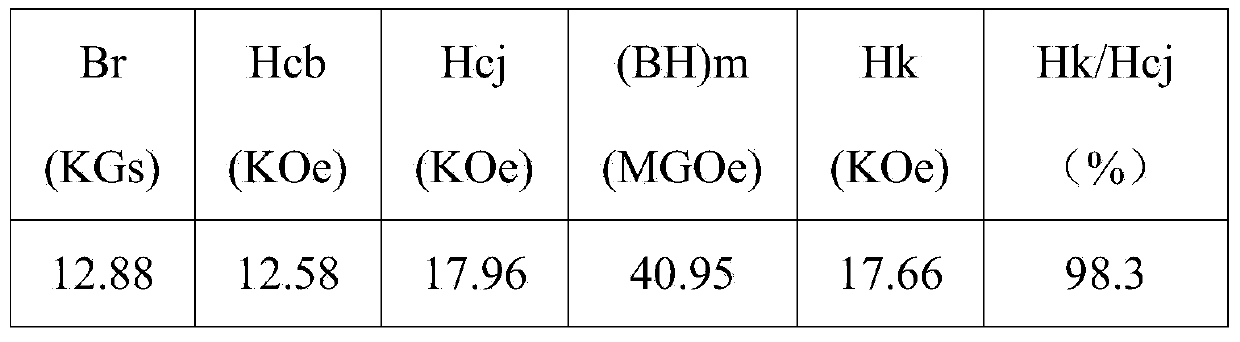

Embodiment 1

[0033] 1) Classify the unqualified NdFeB waste generated in the production process and the leftovers generated by post-processing according to the performance grades, collect and store the NdFeB wastes with the performance grade 40H.

[0034] 2) Each time, put 80kg of NdFeB waste with performance grade 40H and 60kg of white corundum abrasive with a specification of 25x25 into the vibrating finishing machine each time, and then add FX-1 metal cleaning agent with a mass concentration of 2%. 5L, turn on the faucet after turning on the vibrator for 30 minutes, adjust the water volume to 400ml / min, continue to vibrate for 2 hours and then take out the waste.

[0035] 3) Take 15kg of the above-mentioned waste materials that have been treated by vibration and finishing each time and put them into the cleaning drum, place them in the YQ-1004 ultrasonic cleaning tank with a capacity of 80L in the washing machine, start cleaning, and the cleaning drum rotates at a speed of 10 rpm. Rotat...

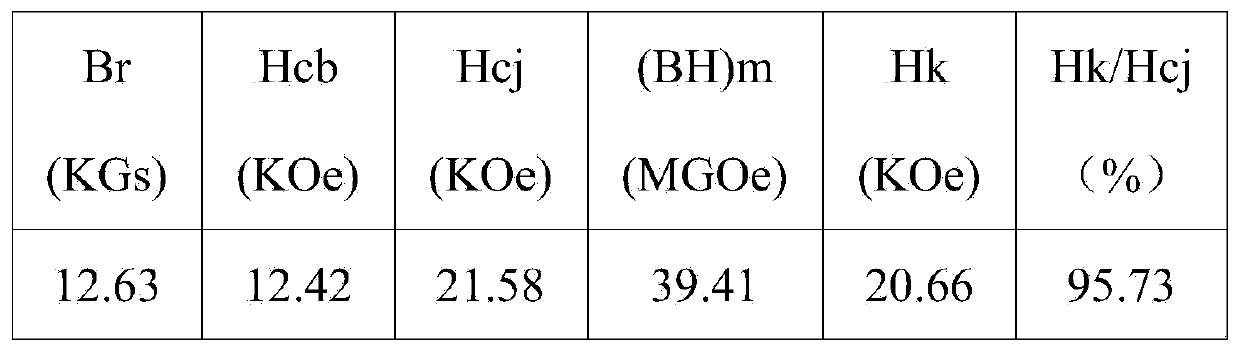

Embodiment 2

[0043] 1) Classify the unqualified NdFeB waste generated in the production process and the leftovers generated by post-processing according to the performance grades, collect and store the NdFeB wastes with the performance grade 38SH.

[0044] 2) Each time, put 90kg of NdFeB scrap with performance grade of 38SH and 65kg of white corundum abrasive with specification of 25x25 into the vibrating finishing machine each time, and then add FX-1 metal cleaning agent with a mass concentration of 4%. 10L, turn on the faucet after turning on the vibrator for 30 minutes, adjust the water volume to 400ml / min, continue to vibrate for 3 hours and then take out the waste.

[0045] 3) Take 25kg of waste materials that have been treated by the above-mentioned vibratory finishing treatment and put them into the cleaning drum, place them in the YQ-1004 ultrasonic cleaning tank of the washing machine, start the cleaning, and the speed of the cleaning drum is 10 rpm. Rotate in the cleaning tank, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com