Preparation method of strontium titanate nano powder

A technology of nano-powder and strontium titanate, which is applied in the field of nanotechnology, can solve the problem that the shape control of strontium titanate nano-powder at the reaction temperature cannot be taken into account, and achieve the goals of lowering the molten salt reaction temperature, low production cost, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

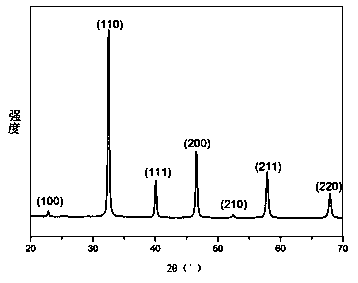

Image

Examples

Embodiment 1

[0033] A preparation method of strontium titanate nanopowder, specifically comprising the following steps:

[0034] (1) At room temperature, grind and mix 1.48g strontium source, 0.8g titanium source, 1.14g NaCl, 1.14g KCl and 1.14g tertiary molten salt in an agate mortar and put them in a corundum crucible, then place The corundum crucible was placed in a muffle furnace to control the temperature at 650°C for molten salt reaction for 6 hours, and after the reaction was completed, it was naturally cooled to room temperature to obtain a reaction solution;

[0035] The amount of strontium source, titanium source, NaCl and KCl used in the above reaction process is calculated by mass ratio, that is, the total mass of strontium source and titanium source: the total mass of NaCl and KCl is 1:1;

[0036] Among them, the strontium source and titanium source are calculated according to the molar ratio of strontium and titanium, that is, strontium: titanium is 1:1;

[0037] The amount ...

Embodiment 2

[0045] A preparation method of strontium titanate nanopowder, specifically comprising the following steps:

[0046] (1) At room temperature, grind and mix 1.48g strontium source, 0.8g titanium source, 1.14g NaCl, 1.14g KCl and 1.14g tertiary molten salt in an agate mortar and put them in a corundum crucible, then place The corundum crucible was placed in a muffle furnace to control the temperature at 650°C for molten salt reaction for 6 hours, and after the reaction was completed, it was naturally cooled to room temperature to obtain a reaction solution;

[0047] The amount of strontium source, titanium source, NaCl and KCl used in the above-mentioned reaction process is calculated by mass ratio, i.e. the total mass of strontium source and titanium source: the total mass of NaCl and KCl is 1:1;

[0048] Among them, strontium source and titanium source are calculated according to the molar ratio of strontium and titanium, that is, strontium:titanium is 1:1;

[0049] The amount...

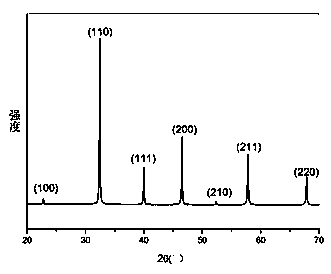

Embodiment 3

[0057] A preparation method of strontium titanate nanopowder, specifically comprising the following steps:

[0058] (1) At room temperature, grind and mix 1.77g strontium source, 0.8g titanium source, 1.285g NaCl, 1.285g KCl and 1.285g tertiary molten salt in an agate mortar and put them in a corundum crucible, then put The corundum crucible was placed in a muffle furnace to control the temperature at 550°C for molten salt reaction for 8 hours, and after the reaction was completed, it was naturally cooled to room temperature to obtain a reaction solution;

[0059] The amount of strontium source, titanium source, NaCl and KCl used in the above reaction process is calculated by mass ratio, that is, the total mass of strontium source and titanium source: the total mass of NaCl and KCl is 1:1;

[0060] Among them, strontium source and titanium source are calculated according to the molar ratio of strontium and titanium, that is, strontium:titanium is 1.2:1;

[0061] The amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com