A kind of method is the method for synthesizing mullite whisker with kalephine as raw material

A technology for synthesizing mullite and potassium nepheline, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of complicated preparation process, high preparation cost, high price and the like, and achieves simplified reaction process, The effect of reducing the reaction temperature of molten salt and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

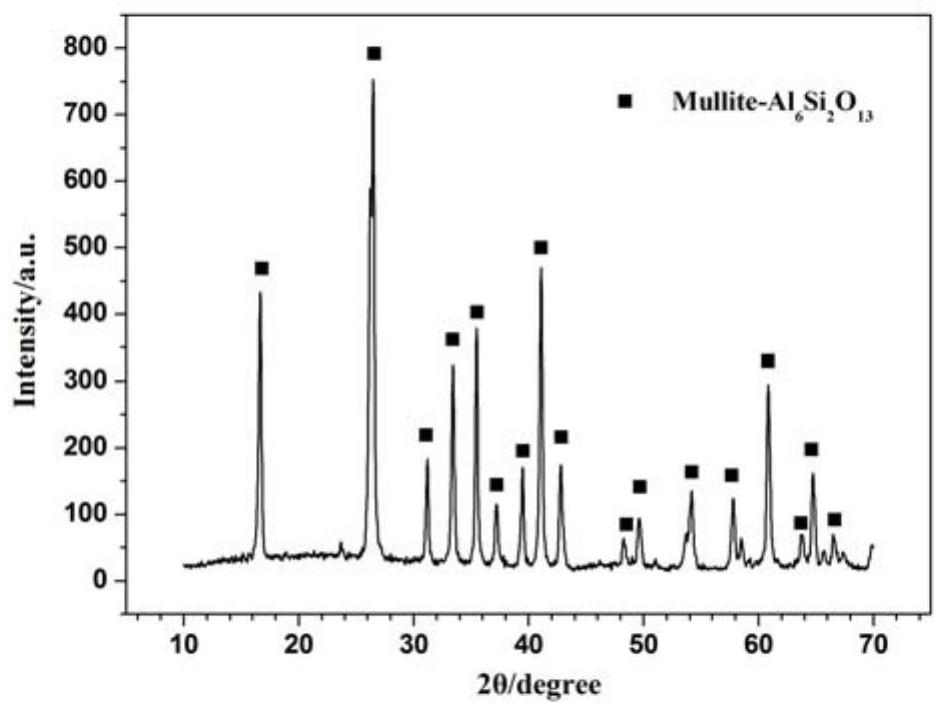

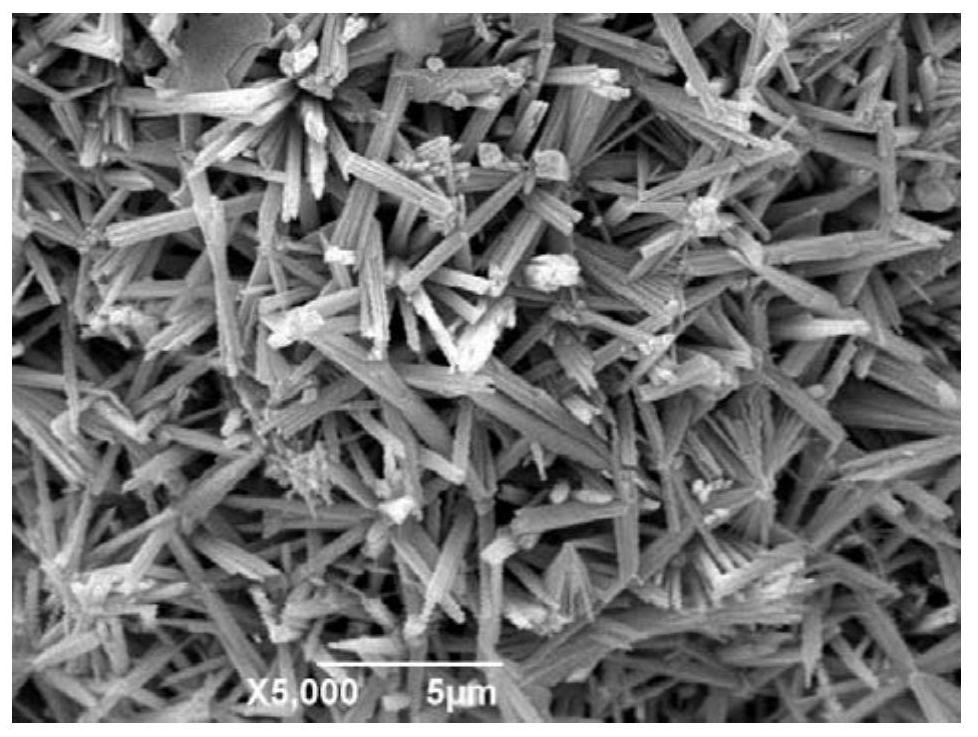

Image

Examples

Embodiment 1

[0021] Step 1: Kalnite, deionized water, H 2 SO 4 (mass concentration 98%) and Al 2 (SO 4 ) 3 Mix at a molar ratio of 1:5:0.1:0.4 to make a suspension;

[0022] Step 2: Add the prepared suspension into the reaction kettle, place the reaction kettle in a microwave hydrothermal reactor for hydrothermal reaction, the reaction temperature is 120°C, the reaction time is 80min, the filling ratio of the reaction kettle is 0.4;

[0023] Step 3: Pour the liquid in the reactor after the microwave hydrothermal reaction into an evaporating dish, and place the evaporating dish in an oven for drying; the drying temperature is 50°C, and the drying time is 10 hours;

[0024] Step 4: Put the dried product in a muffle furnace for molten salt reaction, and the reacted product is ground, washed with water, and centrifuged to remove the molten salt adsorbed on the surface, and the obtained product is mullite whisker. Wherein, the molten salt reaction temperature is 400° C., and the reaction ...

Embodiment 2

[0027] Step 1: Kalnite, deionized water, H 2 SO 4 (mass concentration 98%) and Al 2 (SO 4 ) 3 Mix at a molar ratio of 1:5:0.2:0.6 to make a suspension;

[0028] Step 2: Add the prepared suspension into the reaction kettle, place the reaction kettle in a microwave hydrothermal reactor for hydrothermal reaction, the reaction temperature is 140°C, the reaction time is 60min, the filling ratio of the reaction kettle is 0.5;

[0029] Step 3: Pour the liquid in the reactor after the microwave hydrothermal reaction into an evaporating dish, and place the evaporating dish in an oven for drying; the drying temperature is 60°C, and the drying time is 8 hours;

[0030] Step 4: Put the dried product in a muffle furnace for molten salt reaction, and the reacted product is ground, washed with water, and centrifuged to remove the molten salt adsorbed on the surface, and the obtained product is mullite whisker. Wherein, the molten salt reaction temperature is 500° C., and the reaction t...

Embodiment 3

[0035] Step 1: Kalnite, deionized water, H 2 SO 4 (mass concentration 98%) and Al 2 (SO 4 ) 3 Mix at a molar ratio of 1:5:0.3:0.8 to make a suspension;

[0036] Step 2: Add the prepared suspension into the reaction kettle, place the reaction kettle in a microwave hydrothermal reactor for hydrothermal reaction, the reaction temperature is 160°C, the reaction time is 40min, the filling ratio of the reaction kettle is 0.5;

[0037]Step 3: Pour the liquid in the reactor after the microwave hydrothermal reaction into an evaporating dish, and place the evaporating dish in an oven for drying; the drying temperature is 70°C, and the drying time is 6 hours;

[0038] Step 4: Put the dried product in a muffle furnace for molten salt reaction, and the reacted product is ground, washed with water, and centrifuged to remove the molten salt adsorbed on the surface, and the obtained product is mullite whisker. Wherein, the molten salt reaction temperature is 600° C., and the reaction ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com