Conditioning method of boat reverse-osmosis seawater desalinated water

A technology of reverse osmosis and desalination, which is applied in the conditioning field of ship reverse osmosis desalination water, which can solve the problems of corroded ship water supply pipes, poor stability, lack of nutrients, etc., to reduce corrosion, improve taste and use comfort, Effect of improving water quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

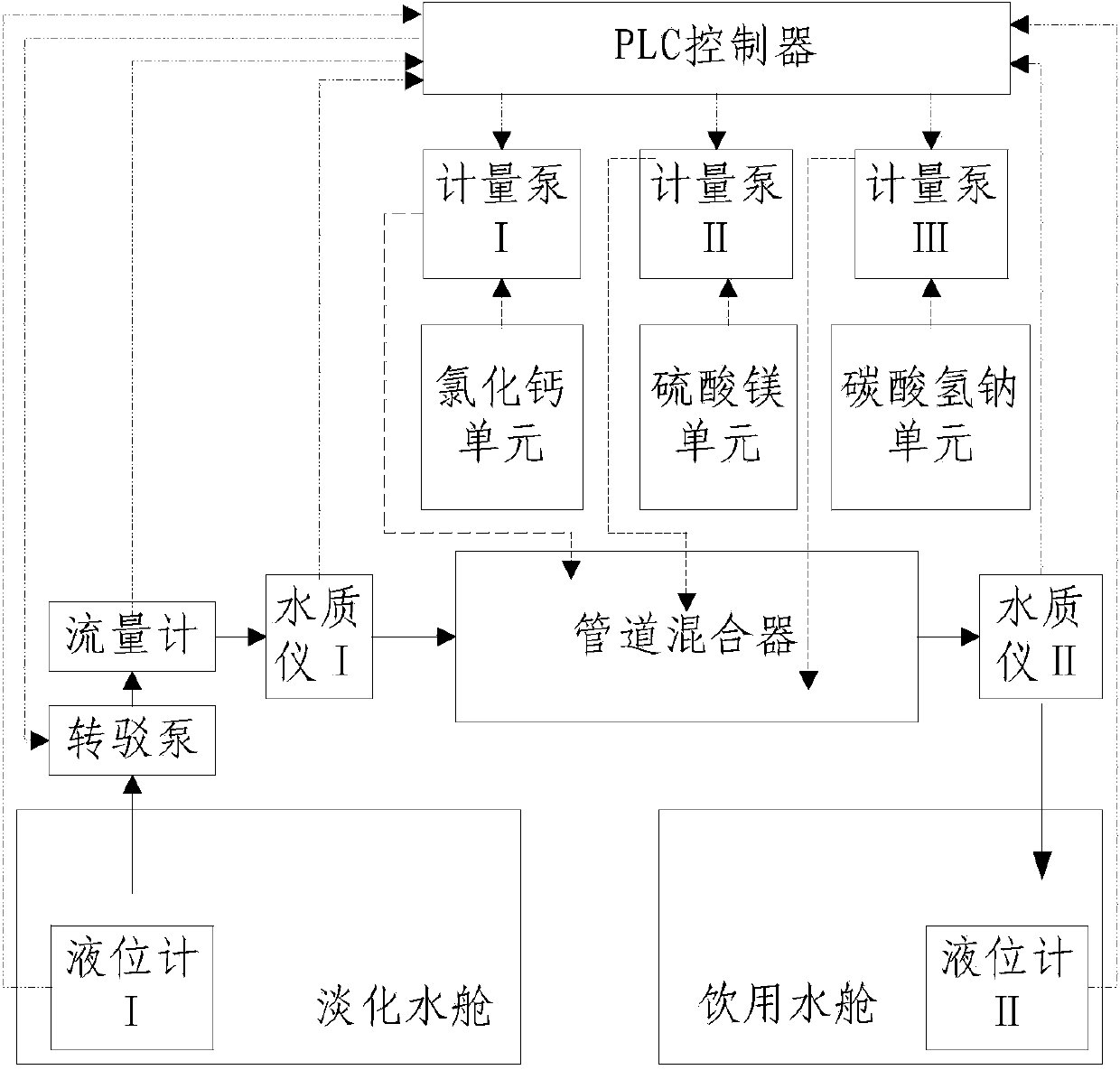

[0038] The following methods are adopted to carry out quenching and tempering treatment of reverse osmosis desalinated water of ships:

[0039] a. The transfer pump pumps the ship's reverse osmosis desalinated water from the ship's water tank;

[0040] b. The water from the transfer pump enters the flowmeter, and the monitored flow rate is 1.5m 3 / h;

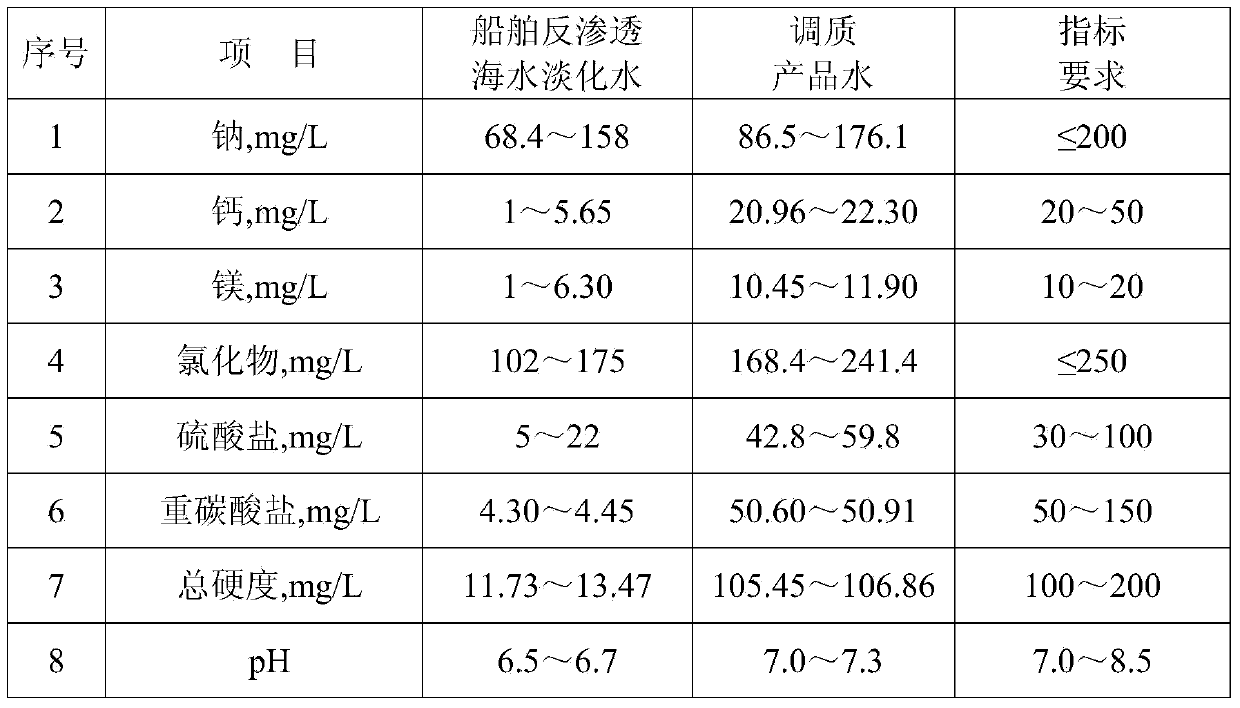

[0041] c. The water quality of the ship’s reverse osmosis desalinated water before conditioning is monitored by the water quality meter I: pH6.5~6.7, total hardness 11.73~13.47mg / L, bicarbonate 4.30~4.45mg / L;

[0042] d. The outlet water of water quality meter I enters the pipeline mixer, and the 2 / 5, 3 / 5, 4 / 5 of the pipeline mixer form an angle of 120° to each other and add calcium chloride, magnesium sulfate and sodium bicarbonate to adjust and temper in sequence along the tangential direction of the water flow agent, the conditioner is dissolved in water quality meter I effluent to form calcium chloride aqueous solution, ma...

Embodiment 2

[0046] The following methods are adopted to carry out quenching and tempering treatment of reverse osmosis desalinated water of ships:

[0047] a. The transfer pump pumps the ship's reverse osmosis desalinated water from the ship's water tank;

[0048]b. The water from the transfer pump enters the flowmeter, and the monitored flow rate is 1.5m 3 / h;

[0049] c. The water quality of the ship’s reverse osmosis desalinated water before conditioning is monitored by the water quality meter I: pH6.5~6.7, total hardness 11.73~13.47mg / L, bicarbonate 4.30~4.45mg / L;

[0050] d. The outlet water of water quality meter I enters the pipeline mixer, and the 2 / 5, 3 / 5, 4 / 5 of the pipeline mixer form an angle of 120° to each other and add calcium chloride, magnesium sulfate and sodium bicarbonate to adjust and temper in sequence along the tangential direction of the water flow agent, the conditioner is dissolved in water quality meter I effluent to form calcium chloride aqueous solution, mag...

Embodiment 3

[0054] The following methods are adopted to carry out quenching and tempering treatment of reverse osmosis desalinated water of ships:

[0055] a. The transfer pump pumps the ship's reverse osmosis desalinated water from the ship's water tank;

[0056] b. The water from the transfer pump enters the flowmeter, and the monitored flow rate is 1.5m 3 / h;

[0057] c. The water quality of the ship’s reverse osmosis desalinated water before conditioning is monitored by the water quality meter I: pH6.5~6.7, total hardness 11.73~13.47mg / L, bicarbonate 4.30~4.45mg / L;

[0058] d. The outlet water of water quality meter I enters the pipeline mixer, and the 2 / 5, 3 / 5, 4 / 5 of the pipeline mixer form an angle of 120° to each other and add calcium chloride, magnesium sulfate and sodium bicarbonate to adjust and temper in sequence along the tangential direction of the water flow agent, the conditioner is dissolved in water quality meter I effluent to form calcium chloride aqueous solution, ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com