Fenton fluidized bed biochemical tail water advanced treatment method

A kind of advanced treatment, fluidized bed technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problem of not maximizing the utilization rate of chemicals, a small amount of iron sludge, etc. The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

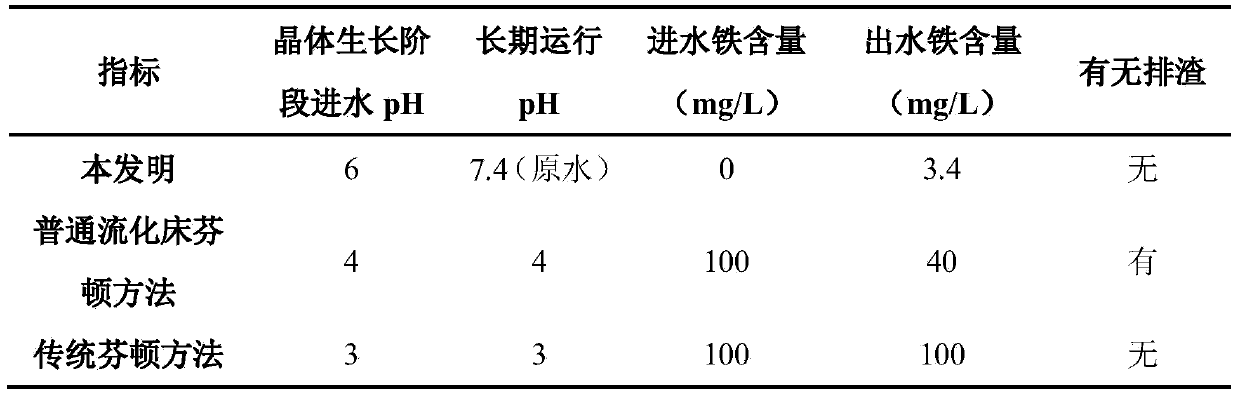

Embodiment 1

[0032] A method for advanced treatment of biochemical tail water in a Fenton fluidized bed, the steps of which are:

[0033] (1) Add 80g / L yellow sand with a particle size of 0.2mm in the fluidized bed;

[0034] (2) Adjust the pH of the influent to 6.0, control the influent flow rate, and keep the residence time in the fluidized bed at 30 minutes;

[0035] (3) Control the rising velocity of the liquid in the fluidized bed to be 30m / h by returning the water outlet part from the top of the fluidized bed to the bottom, and add hydrogen peroxide and ferrous sulfate solution in the fluidized bed to react respectively, and the dosage of hydrogen peroxide is 2mM, the hydrogen peroxide with a mass fraction of 30% was diluted 10 times before adding, and the dosage of ferrous sulfate in the crystal growth stage was 100mg / L;

[0036] (4) Maintain conditions (1)-(3), and run continuously for 2 weeks to carry out crystal growth on the filler surface (crystal growth stage);

[0037] (5) A...

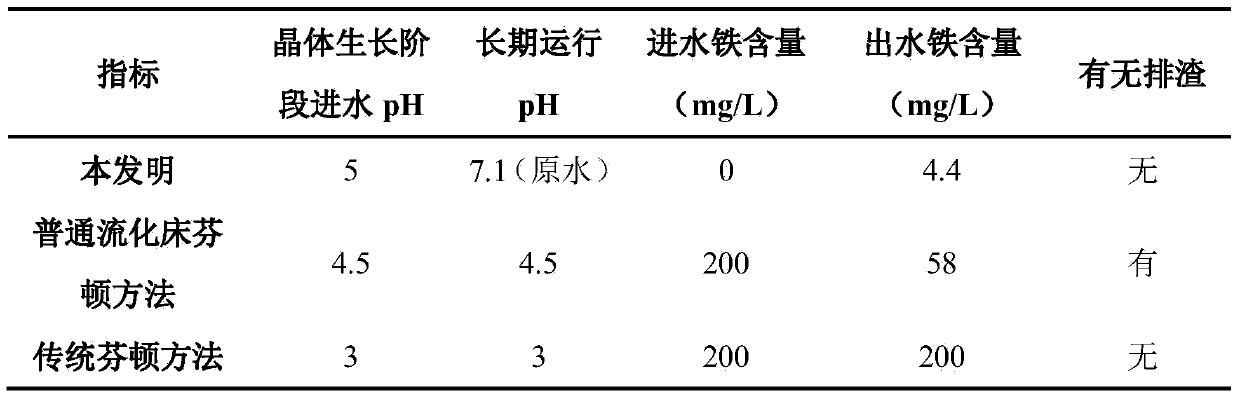

Embodiment 2

[0044] A method for advanced treatment of biochemical tail water in a Fenton fluidized bed, the steps of which are:

[0045] (1) Add 100g / L quartz sand with a particle size of 0.4mm in the fluidized bed;

[0046](2) Adjust the pH of the influent to 5.0, control the influent flow, and keep the residence time in the fluidized bed at 45 minutes;

[0047] (3) Control the ascending flow rate of the liquid in the fluidized bed to 50m / h by returning the water outlet part from the top of the fluidized bed to the bottom, and add hydrogen peroxide and ferrous sulfate solution in the fluidized bed to react, and the dosage of hydrogen peroxide is 5mM, the hydrogen peroxide with a mass fraction of 30% was diluted 10 times before adding, and the dosage of ferrous sulfate in the crystal growth stage was 200mg / L;

[0048] (4) Maintain conditions (1)-(3), and operate continuously for 3 weeks for crystal growth (crystal growth stage);

[0049] (5) After the crystal growth ends, the pH of the ...

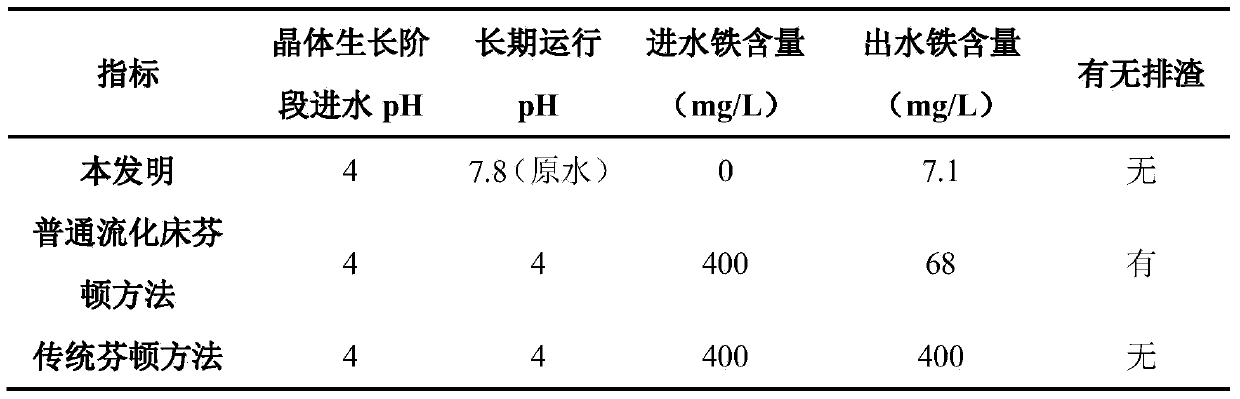

Embodiment 3

[0056] A method for advanced treatment of biochemical tail water in a Fenton fluidized bed, the steps of which are:

[0057] (1) Add 120g / L zeolite in the fluidized bed with a particle size of 0.6mm;

[0058] (2) Adjust the pH of the influent to 4.0, control the influent flow rate, and keep the residence time in the fluidized bed at 60 minutes;

[0059] (3) Control the ascending flow rate of the liquid in the fluidized bed to be 80m / h by returning the water outlet part from the top of the fluidized bed to the bottom, and add hydrogen peroxide and ferrous sulfate solution in the fluidized bed to react, and the dosage of hydrogen peroxide is 10mM, the hydrogen peroxide with a mass fraction of 30% was diluted 10 times before adding, and the dosage of ferrous sulfate in the crystal growth stage was 400mg / L;

[0060] (4) Maintain conditions (1)-(3), and operate continuously for 4 weeks for crystal growth (crystal growth stage);

[0061] (5) After the crystal growth ends, the pH o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com