A membrane bioreactor

A membrane bioreactor and filter membrane technology, applied in the field of water purification treatment, can solve the problems of restricting the development of membrane bioreactor technology, high cost per ton of water treatment, high energy consumption, etc., and achieve effective cleaning and unit energy consumption. Low, fast backwash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

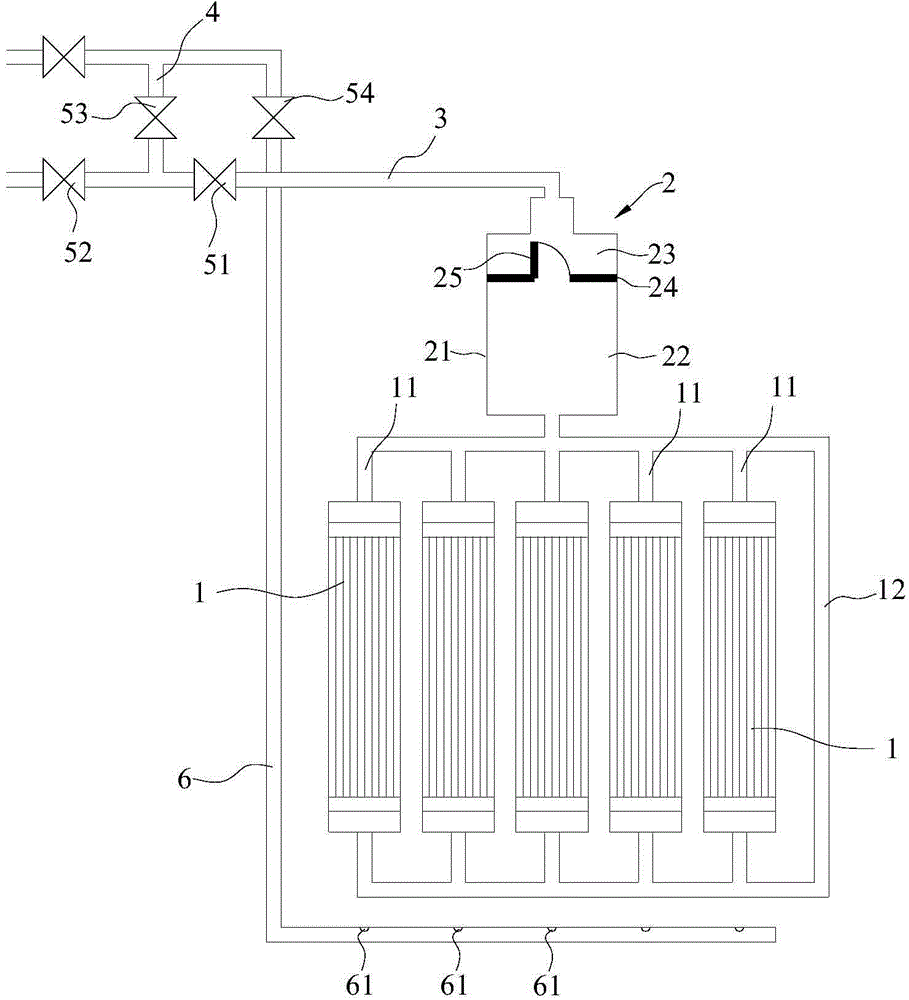

[0024] refer to figure 1 , the present invention provides a membrane bioreactor, including a membrane module 1 and a gas-water separation device 2 that can be placed in the mud-water mixture, the membrane module 1 includes an ultrafiltration membrane and the product water formed by the filtration membrane chamber, the inner cavity of the water production is communicated with the gas-water separation device 2 through the water production pipe, and the gas-water separation device 2 includes a piston cylinder 21 and is arranged in the piston cylinder 21 and the inner cavity of the piston cylinder 21 Divided into the piston 24 of the front chamber 22 and the rear chamber 23, the piston 24 is provided with a one-way valve 25 that can lead the direction of the front chamber 22 to the rear chamber 23, and the water production pipe communicates with the front chamber 22 of the piston barrel 21 , communicate with the rear cavity 23 of the piston barrel 21 and be provided with an outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com