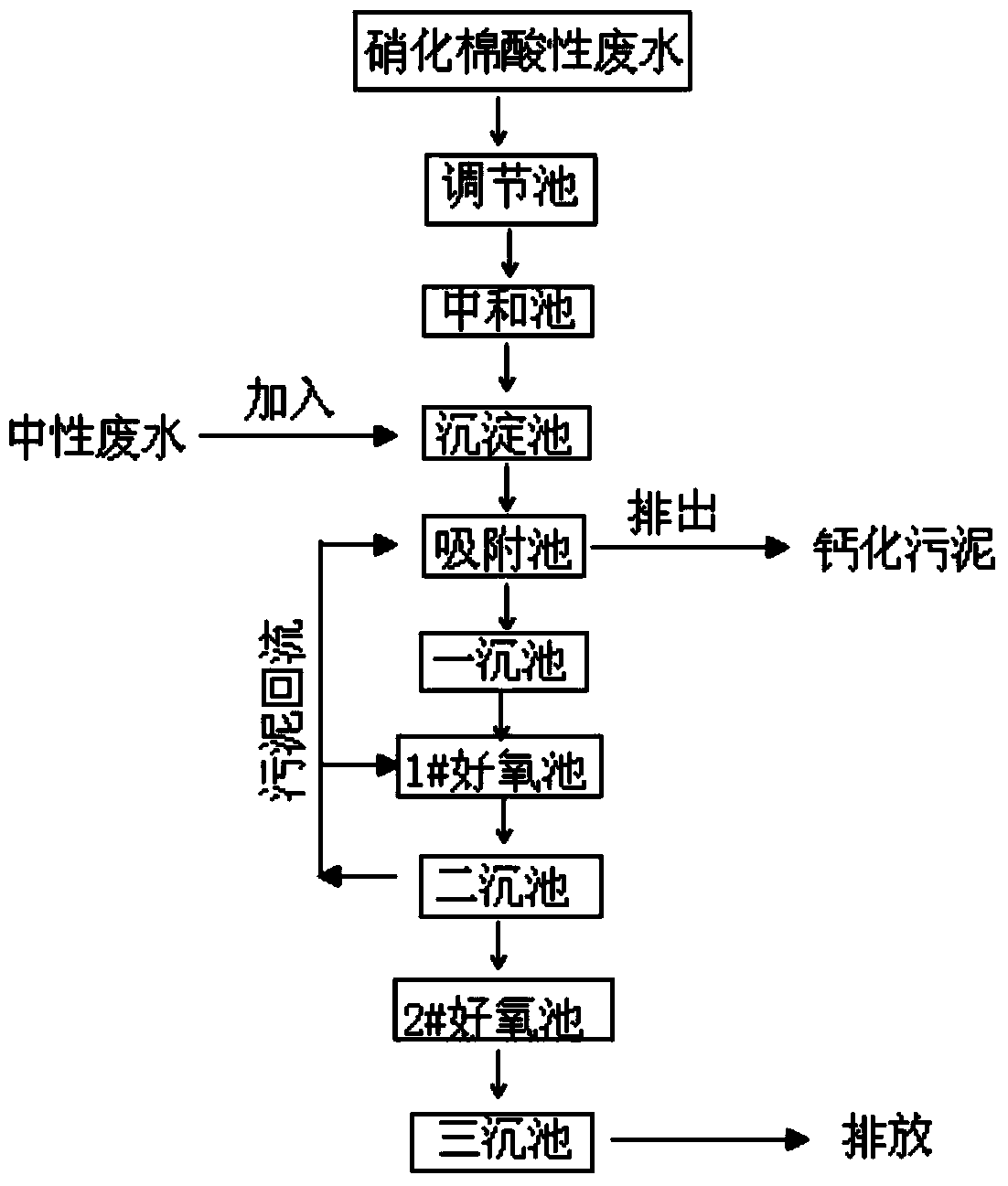

Biochemical treatment process of nitrocotton acidic wastewater

A technology for biochemical treatment and acidic wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, low discharge compliance rate, low biochemical efficiency, etc. Achieve the effect of reducing operating costs, eliminating environmental pollution problems, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 The biochemical treatment process of the nitrocellulose acid wastewater provided by the present invention operates within one month:

[0050] The nitrocellulose acid wastewater entering the treatment station first enters the regulating tank, the average COD is 454mg / L, the average acidity is 4.7g / L, and the average daily water volume is 3420m 3 After being neutralized by milk of lime (pH3.2-4.2), it enters the sedimentation tank and introduces neutral water at the same time. The average COD value of the sedimentation tank is measured to be 421mg / L, and the pH is 4.6-5.4 (lime will contain a small amount of calcium carbonate, carbonic acid Calcium participates in the neutralization of CO 2 , CO 2 Gradual release from water raises the pH; introduction of neutral water also raises the pH). Then use the pump to send water to the adsorption pool, and measure the pH of the adsorption pool to be 6.8 to 7.3 (the pH of the adsorption pool increases under the actio...

Embodiment 2

[0051] Embodiment 2 processing cost comparison

[0052] Calculated by treating 4,500 tons of wastewater per day:

[0053] The biochemical treatment process of nitrocellulose acid wastewater provided by the invention reduces the cost of PAC and PAM agents by 0.65 yuan / ton of wastewater. At the same time, the cost of medicament configuration, water and electricity consumption and facility repair and maintenance costs are reduced, and labor costs are reduced. It also reduces the chemical sludge produced by adding PAC and PAM agents, reducing the cost of this part of sludge treatment by 0.1 yuan / ton of wastewater. There is currently no good method for the disposal of chemical sludge, and the cost cannot be estimated.

[0054] The biochemical treatment process of nitrocellulose acid wastewater provided by the invention separates the neutral wastewater of the production line from the total wastewater, reduces the amount of acid water treatment, relatively increases the reaction ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com