High-temperature sintered painted sand and preparation method thereof

A technology of high temperature sintering and colored sand, applied in the field of colored sand, can solve the problems of difficult control of color adjustment of colored sand, inconvenient for large-scale application, and difficulty in continuous production, etc., to achieve convenient large-scale application, easy adjustment and control, consistent Sexually easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

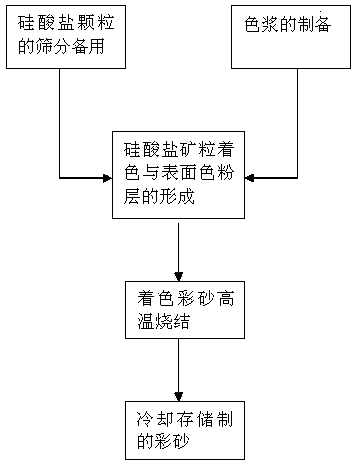

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: The preparation of yellow high-temperature sintered colored sand specifically includes the following steps:

[0032] (1) Select and screen the quartz sand ore grains: directly select 6# sand from the quartz sand ore, and screen with a sieve for spare use. The particle size distribution is: 40-120 mesh: 95%, 120-200 Mesh: 0%, below 40 mesh: 5%;

[0033] (2) Preparation of color paste: According to the required color, mix 250kg of water glass, 190kg of kaolin, 90kg of industrial borax, 70kg of inorganic titanium yellow powder and 400kg of water, and put it into a ball mill for 1.2 hours to make the fineness reach: 325 The mesh sieve residue is less than 0.5%, and the fineness is qualified and put into the storage tank for standby;

[0034] (3) Coloring of quartz sand ore particles and formation of surface toner layer: Adjust the output of the rotary drum furnace to 2 tons per hour, and continuously and evenly introduce the quartz sand ore particles into the...

Embodiment 2

[0037] Embodiment 2: The preparation of green high-temperature sintered colored sand specifically includes the following steps:

[0038] (1) Select and screen the quartz sand ore grains: directly select 6# sand from the quartz sand ore, and screen with a sieve for backup, and the particle size gradation is: 40-120 mesh: 80%, 120-200 Mesh: 20%, below 40 mesh: 0%;

[0039] (2) Preparation of root color paste: According to the required color, mix 200kg of water glass, 170kg of kaolin, 100kg of industrial borax, 80kg of chrome green powder and 450kg of water, and put it into a ball mill for 0.8 hours to make the fineness reach: 325 The mesh sieve residue is less than 0.5%, and the fineness is qualified and put into the storage tank for standby;

[0040] (3) Coloring of quartz sand ore particles and formation of surface toner layer: Adjust the output of the rotary drum furnace to 2 tons per hour, and continuously and evenly introduce the quartz sand ore particles into the rotary d...

Embodiment 3

[0043] Embodiment 3: the preparation of black high-temperature sintered colored sand specifically comprises the following steps:

[0044](1) Select and screen the quartz sand ore grains: directly select 7# sand from the quartz sand ore, and screen with a sieve for backup, and the particle size gradation is: 40-120 mesh: 60%, 120-200 Mesh: 35%, below 40 mesh: 5%;

[0045] (2) Preparation of color paste: According to the required color, mix 300kg of water glass, 170kg of kaolin, 50kg of industrial borax, 180kg of cobalt black powder and 300kg of water, and put it into a ball mill for 1.3 hours to make the fineness reach: 325 mesh The sieve residue is less than 0.3%, and the fineness is qualified and put into the storage tank for standby;

[0046] (3) Coloring of quartz sand ore particles and formation of surface toner layer: Adjust the output of the rotary drum furnace to 2 tons per hour, and continuously and evenly introduce the quartz sand ore particles into the rotary drum f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com