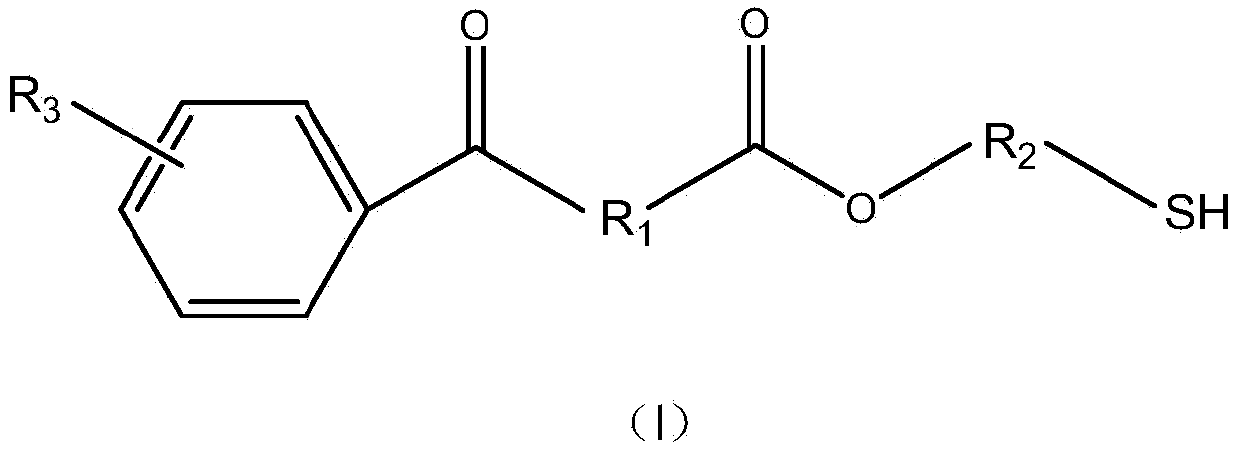

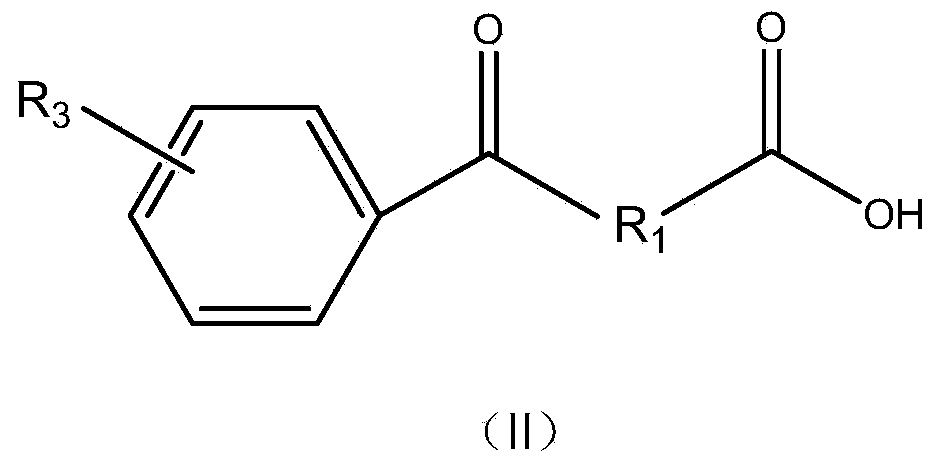

Benzoyl sulfydryl ester compound as well as preparation method and application thereof

A technology of benzoyl mercapto ester and compound, which is applied in the application of emulsion polymerization emulsifier, benzoyl mercapto ester compound and its preparation field, can solve the problems of easy bubble stability, environmental pollution, easy generation of gel, etc. Purity, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

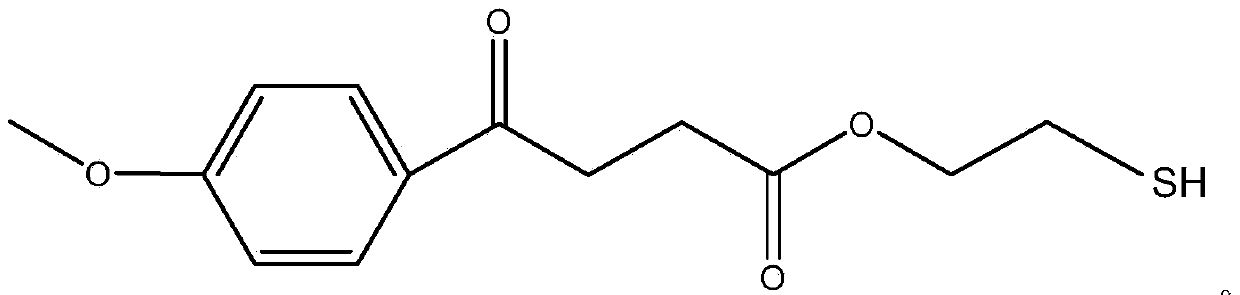

[0035] The benzoyl mercapto ester compound provided in this example is mercaptoethyl 4-p-methoxyphenyl-4-oxobutyrate, and its chemical formula is as follows.

[0036]

[0037] The preparation method of this compound is:

[0038] Add 200 parts by weight of 4-p-methoxyphenyl-4-oxobutanoic acid, 70 parts by weight of mercaptoethanol, 0.5 parts by weight of sodium hydroxide, 4 parts by weight of tin protochloride, and 0.01 parts by weight of silver powder in a four-necked flask (300 mesh), pass into nitrogen protection, reflux at 75°C for 4 hours, separate the precipitate, then add about 300 parts by weight of deionized water at 5°C and 10 parts by weight of 1N hydrochloric acid, stir for 10 minutes, and let stand for 30 minutes. And keep the solution temperature below 10°C, and white crystals are precipitated, which is mercaptoethyl 4-p-methoxyphenyl-4-oxobutanoate.

Embodiment 2

[0040] The benzoyl mercapto ester compound provided in this example is 4-mercaptopropyl 4-methoxyphenyl-4-oxobutyrate, and its chemical formula is as follows.

[0041]

[0042] The preparation method of this compound is:

[0043] Add 300 parts by weight of 4-p-methoxyphenyl-4-oxobutanoic acid, 100 parts by weight of mercaptopropanol, 1 part by weight of sodium hydroxide, 2 parts by weight of tin protochloride, 0.03 parts by weight of Silver powder (300 mesh), nitrogen protection, reflux reaction at 85°C for 3 hours, separate the precipitate, then add 300 parts by weight of deionized water at about 5°C and 10 parts by weight of 1N hydrochloric acid, stir for 10 minutes, and let stand for 30 minutes , and keep the solution temperature below 10°C, white crystals are precipitated, which is 4-mercaptopropyl 4-methoxyphenyl-4-oxobutanoate.

Embodiment 3

[0045] The benzoyl mercapto ester compound provided in this example is 4-p-methoxyphenyl-4-oxobutanoic acid-(2,2'-dimethyl)mercaptopropyl ester, and its chemical formula is as follows.

[0046]

[0047] The preparation method of this compound is:

[0048]Add 250 parts by weight of 4-p-methoxyphenyl-4-oxobutanoic acid, 85 parts by weight of (2,2'-dimethyl)-1-mercaptopropanol, 0.75 parts by weight of Sodium, 3 parts by weight of stannous chloride, 0.02 parts by weight of silver powder (300 mesh), nitrogen protection, reflux at 80 ° C for 3.5 hours, separate the precipitate, then add about 5 ° C 300 parts by weight of deionized water and 1N 10 parts by weight of hydrochloric acid, stirred for 10 minutes, allowed to stand for 30 minutes, and kept the solution temperature below 10°C, and white crystals were precipitated, namely 4-p-methoxyphenyl-4-oxobutanoic acid-(2,2'- Dimethyl) mercaptopropyl ester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com