Furan resin for cast steel and synthesis method thereof

A technology of furan resin and synthesis method, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as environmental pollution, achieve the effects of reducing production costs, smoothing the surface, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

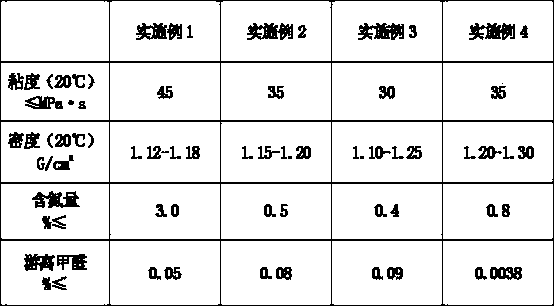

Examples

Embodiment 1

[0030] It is made from 780kg of furfuryl alcohol, 91kg of solid formaldehyde, 100kg of phenol, 6.5kg of urea, 2kg of silane coupling agent and 20.5kg of water, through the following steps:

[0031] (1) Add phenol and water into the reaction kettle, start the mixer to stir, and adjust the pH value to 8.5-9.5 with sodium hydroxide;

[0032] (2) Add urea and solid formaldehyde, add steam to raise the temperature, keep raising the temperature by 8°C every 5 minutes, then raise the temperature to 90°C, and keep it warm for 50 minutes;

[0033] (3) Cool down to below 80°C, add furfuryl alcohol, and adjust the pH value to 9.5-10.5 with sodium hydroxide;

[0034] (4) Add steam to raise the temperature to 105-115°C, keep warm and reflux for 80-100 minutes;

[0035] (5) Cool down to 50°C, add furfuryl alcohol and silane coupling agent, stir evenly to obtain the finished product.

[0036] The solid formaldehyde is paraformaldehyde with a low degree of polymerization, and the content is...

Embodiment 2

[0039] It is prepared from 712kg of furfuryl alcohol, 107kg of solid formaldehyde, 120kg of phenol, 11kg of urea, silane coupling agent X-602, 5kg of γ-aminopropyltriethoxysilane, and 45kg of water through the following steps:

[0040] (1) Add phenol and water into the reaction kettle, start the mixer to stir, and adjust the pH value to 8.5-9.5 with potassium hydroxide;

[0041](2) Add urea and solid formaldehyde, add steam to raise the temperature, keep raising the temperature by 8°C every 5 minutes, then raise the temperature to 90°C, and keep it warm for 55 minutes;

[0042] (3) Cool down to below 80°C, add furfuryl alcohol, and adjust the pH value to 9.5-10.5 with potassium hydroxide;

[0043] (4) Add steam to raise the temperature to 105-115°C, keep warm and reflux for 80-100 minutes;

[0044] (5) Cool down to 50°C, add the mixture of furfuryl alcohol, silane coupling agent X-602 and γ-aminopropyltriethoxysilane, stir well to get the finished product.

[0045] The solid...

Embodiment 3

[0048] It is made from 704kg of furfuryl alcohol, 115kg of solid formaldehyde, 130kg of phenol, 17.5kg of urea, 4kg of γ-methacryloxypropyltrimethoxysilane and 30kg of water through the following steps:

[0049] (1) Add phenol and water into the reaction kettle, start the mixer to stir, and adjust the pH value to 8.5-9.5 with melamine and sodium hydroxide;

[0050] (2) Add urea and solid formaldehyde, add steam to raise the temperature, keep raising the temperature by 8°C every 5 minutes, then raise the temperature to 90°C, and keep it warm for 60 minutes;

[0051] (3) Cool down to below 80°C, add furfuryl alcohol, and adjust the pH value to 9.5-10.5 with melamine and sodium hydroxide;

[0052] (4) Add steam to raise the temperature to 105-115°C, keep warm and reflux for 80-100 minutes;

[0053] (5) Cool down to 50°C, add furfuryl alcohol and γ-methacryloxypropyltrimethoxysilane, stir evenly to obtain the finished product.

[0054] The solid formaldehyde is paraformaldehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com